What Is Open Die Forging?

What is open die forging, and why is it so critical for industries requiring large, high-strength, and high-performance components? From aerospace to energy and heavy machinery, the process plays a pivotal role in producing durable parts. Unlike closed die forging, which uses enclosed molds, open die forging shapes metal in an open mold, enabling the creation of large parts with excellent adaptability. This flexibility makes it a preferred method for applications such as aircraft engines, turbine shafts, and mining equipment.

What Is Open Die Forging?

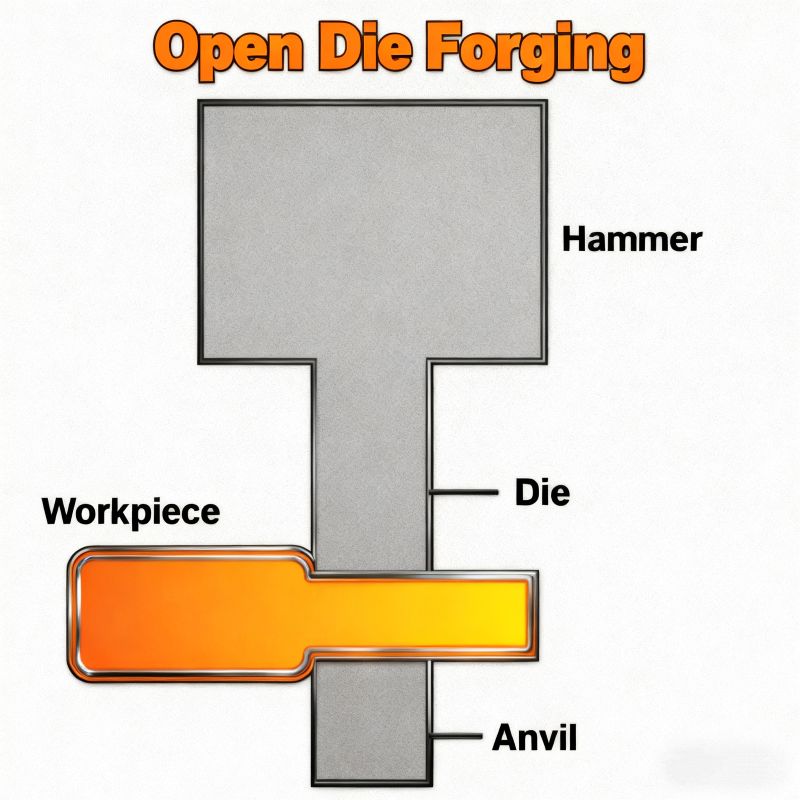

Open die forging is a metal forming process where a heated billet is placed between two dies that do not completely enclose the material. Under controlled pressure, the billet is hammered or pressed repeatedly until it achieves the desired shape. Because the metal can freely flow, this process is especially suited for producing large or custom components that casting or closed die methods cannot easily achieve.

The method typically involves heating the billet to forging temperature and applying repeated strikes or compressions. This controlled deformation not only improves grain structure but also enhances strength and fatigue resistance. As a result, it is widely used in aerospace, energy, and heavy machinery, where durable and precision-engineered components are critical.

The Open Die Forging Process

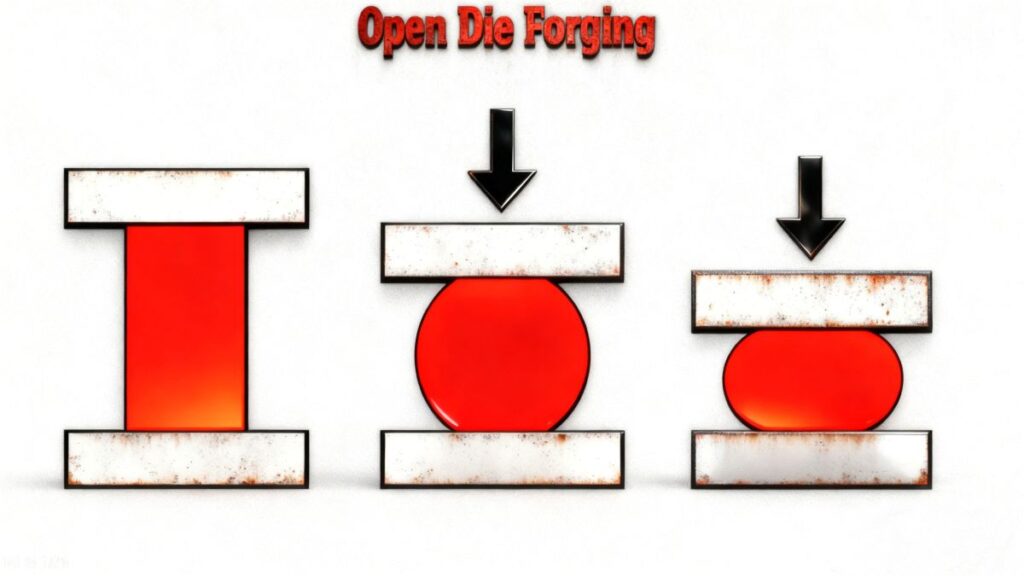

The open die forging process begins with heating a metal billet to the ideal temperature for forming. Once heated, the billet is positioned between the open dies, where controlled pressure shapes the material through repeated strikes or gradual compression. This method not only creates the desired geometry but also refines the internal grain structure, enhancing overall strength and durability.

The main stages of the forging process include:

- Heating – The billet is brought to the proper temperature, improving its plasticity and making it easier to form.

- Forging – Under precise pressure, the heated billet is shaped between the dies. The metal gradually takes form, achieving the required dimensions while maintaining excellent structural integrity.

- Cooling and Heat Treatment – After shaping, the part is cooled in a controlled manner. Additional processes such as quenching and tempering may be applied to further improve hardness and performance.

- Final Processing – To achieve exact specifications, post-forging operations such as CNC machining or surface finishing are carried out, ensuring accuracy, smoothness, and readiness for application.

Advantages

Open die forging provides major advantages in strength, flexibility, and material efficiency.

Strength and Reliability: Refined grain flow improves tensile strength and fatigue performance.

Large Part Capability: Suitable for oversized components like turbine shafts and press columns.

Efficient Material Use: Produces less waste than casting, reducing overall material costs.

Customizable Shapes: Supports tailored dimensions and performance based on engineering requirements.

Common Defects in Open-Die Forgings

Although open-die forging greatly enhances internal grain flow and mechanical strength, certain metallurgical challenges may arise if process control is not carefully managed. Typical considerations include:

Porosity or insufficient consolidation, often related to limited deformation under compression

Surface discontinuities, which may occur if the forging temperature exceeds optimal limits

Segregation tendencies, especially in large cross-section steel ingots where uniform cooling is critical

Residual inclusions, influenced by initial raw material cleanliness

Layer separation, which can appear when billet reduction steps are not properly optimized

With a well-designed forging process, appropriate deformation ratios, and precise temperature control, these potential issues can be minimized or fully eliminated—resulting in a more stable, high-performance forged component ready for machining and final assembly.

Non-Destructive Testing (UT & MPI) for Open-Die Forgings

To ensure structural integrity and traceable quality assurance, Weforging conducts full NDT (Non-Destructive Testing) on all critical forged components according to global industrial standards.

Ultrasonic Testing (UT)

Ultrasonic Testing is used to detect internal defects such as porosity, disbonds, and shrinkage cavities in thick-section or high-strength components.

-

Test standard reference: ASTM A388 / EN10228-3

-

Suitable for shafts, cylinders, rings, blocks, and heavy-duty engineering parts

-

Typical acceptance level: Level 2 or better

Magnetic Particle Inspection (MPI)

Magnetic Particle Inspection reveals surface or near-surface defects, such as fatigue cracks or forging laps.

-

Standard reference: ASTM E709 / ISO 9934

-

Applied to machined surfaces or final-forging surfaces

-

Suitable for alloy steel, carbon steel, and tool steel forgings

In metal forming, open die forging and closed die forging are two primary methods, each with its own unique advantages and applications.

Feature | Open Die Forging | Closed Die Forging |

Process | Uses open molds where the metal is free to flow, suitable for large and complex parts. | Uses fully enclosed molds, ideal for mass production with precise dimensions. |

Advantages | Flexible, ideal for custom production and small batch runs, produces larger parts. | Suitable for mass production, highly accurate and consistent, faster for standard parts. |

Applications | Aerospace, energy, heavy machinery, custom parts. | Automotive, electronics, high-volume standard parts. |

Applications and Types

Open die forging is widely used to manufacture large, high-strength components as well as medium-sized parts that benefit from reliable durability. During deformation, the process refines the metal’s grain structure, supporting improved toughness and fatigue performance. As a result, open die forging is commonly applied in industries with high safety and performance expectations, including aerospace, wind power, automotive, and heavy equipment.

From a geometric perspective, this forging method is particularly well suited for the following component categories:

Cylindrical components – shafts, bars, and spindles

Flat shapes – forged discs and plate-like parts

Hollow forms – rings, sleeves, and tubular components

Contoured parts – hubs, stepped shafts, and structural forgings

In practical applications, open die forged products such as discs, hollow rings, gear rings, and structural components are widely used in power generation, mining equipment, and construction machinery.

How to Choose the Right Open Die Forging Company

When selecting an open die forging supplier, procurement teams should consider several key factors to ensure quality and long-term performance.

Material Quality: Using high-grade raw materials helps ensure durable, reliable forged parts. A trustworthy supplier maintains stable metallurgical performance throughout production.

Technical Capability: With strong engineering expertise, the right forging partner can produce large or complex components while maintaining precision and structural integrity.

Reliable Delivery: In addition, a consistent delivery record helps keep projects on schedule and reduces downtime across production lines.

Testing and Certification: More importantly, suppliers that perform ultrasonic testing, hardness checks, and metallographic analysis can ensure compliance with international safety and performance standards.

By evaluating these aspects, procurement teams can build a dependable partnership with a capable forging company that supports efficient operations and long-term project success.

Conclusion

Open die forging provides excellent strength, flexibility, and customization, making it ideal for large, high-performance components in industries like automotive, mining, and energy. Its high efficiency and low material waste ensure lasting value in modern manufacturing.

At Weforging, we combine advanced forging equipment, CNC precision, and strict testing to deliver reliable open die forging solutions. Whether standard or custom parts, we support your project with durable, high-quality components.

📩 Contact us to learn how our open die forging can support your needs.