What is Cold Forging

Cold forging is a widely used metal forming process carried out at room or near-room temperature. By applying immense pressure without heating, it reduces oxidation and saves energy. The method is ideal for producing precise, durable cold forged parts such as bolts, nuts, gears, and shafts with excellent surface finish and strength. Thanks to its efficiency and accuracy, cold forging applications are common in automotive, aerospace, hardware, and industrial sectors, where high-performance and cost-effective components are required. Together with other forging techniques, it plays a vital role in meeting modern manufacturing demands.

Understanding Cold Forging

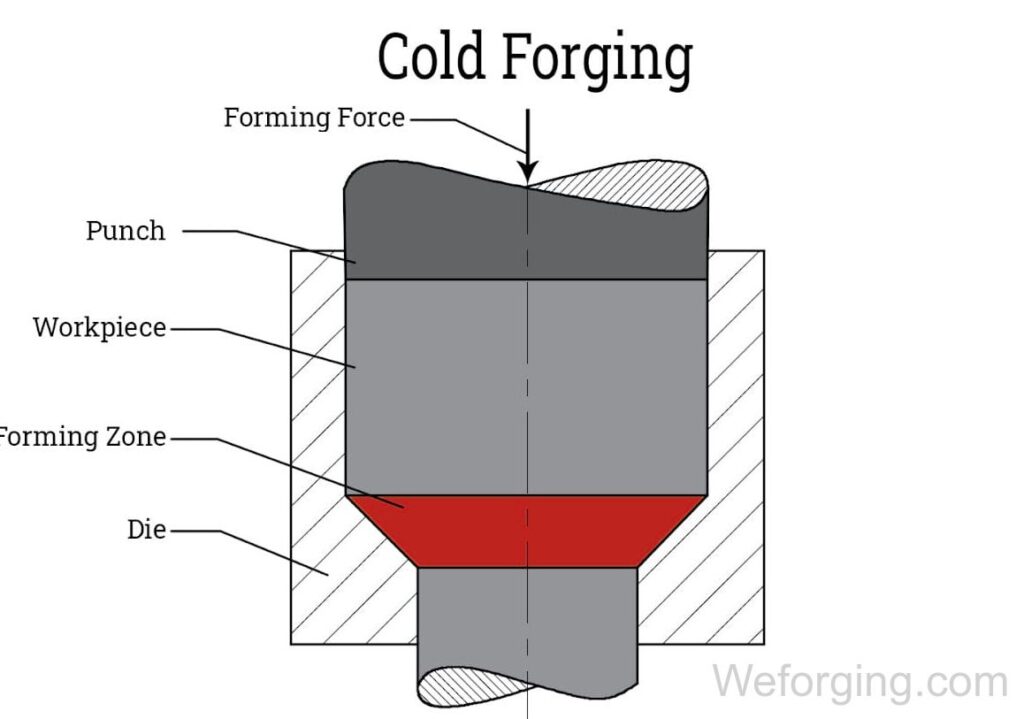

Cold forging is a specialized metal forming process performed below the metal’s recrystallization temperature. Instead of heating the material, manufacturers apply extremely high pressure through dies and presses to shape the metal. This allows the production of cold forged parts with outstanding strength, hardness, and dimensional accuracy.

Because the process avoids high-temperature exposure, parts produced through cold forging have smoother surfaces and tighter tolerances, often requiring little or no secondary machining. In addition, the grain structure of the material is refined during deformation, which enhances durability and performance.

The Cold Forging Process

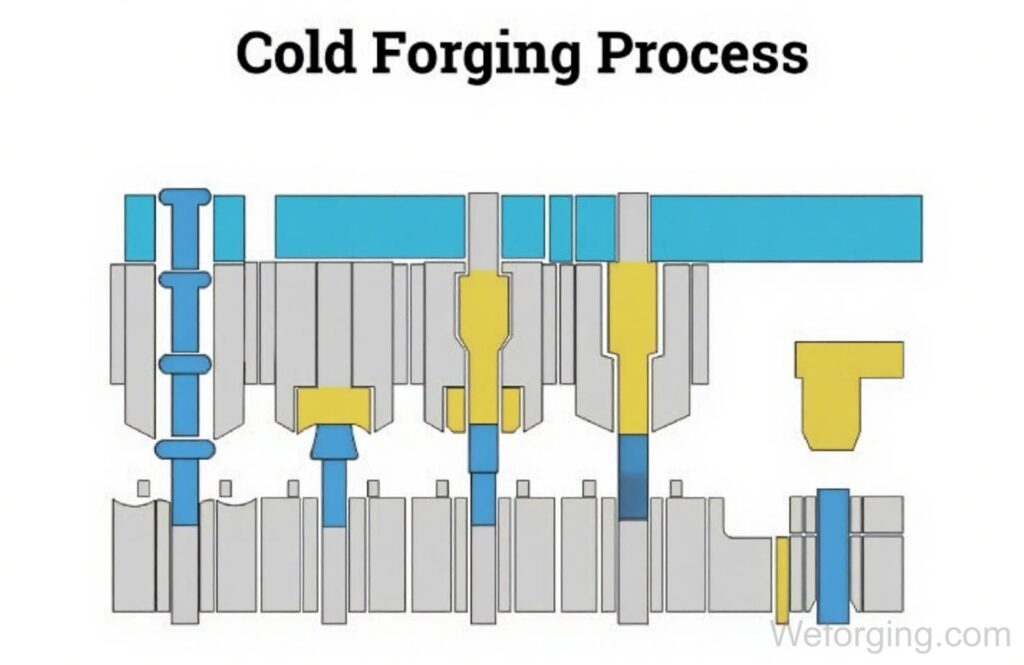

The process typically involves three main stages: billet preparation, die forming, and post-processing. It is one of the most widely used forging techniques in mass production because it delivers high material efficiency, excellent mechanical properties, and consistent part quality.

The steps include:

- Billet preparation – The raw metal is cleaned, pickled, and lubricated to reduce friction and protect the tooling.

- Die forming – The billet is placed into a precision die and shaped under immense compressive force.

- Post-processing – Additional treatments such as heat treatment, deburring, or surface finishing are applied to enhance performance and appearance.

Advantages of Cold Forging

Cold forging offers several advantages that make it ideal for high-volume production:

High accuracy and surface quality — Delivers tight tolerances and smooth finishes for precision parts.

Energy efficiency — Operates without heating, reducing energy use and lowering production cost.

Excellent material utilization — Uses nearly all material with minimal waste.

Improved mechanical properties — Cold working strengthens grain structure, increasing hardness and long-term durability.

Limitations to Consider

Despite its benefits, cold forging has some limitations:

– Works best with ductile materials (mild steel, aluminum, copper).

– High tooling costs due to die strength requirements.

– Shape complexity may require secondary machining.

– Best suited for high-volume production runs.

Explore our engineering & mining solutions:Engineering & Mining Components

Industrial Applications

Key cold forging applications include:

– Automotive – gears, bolts, nuts, shafts, bearings.

– Aerospace – high-strength fasteners, connectors, structural parts.

– Hardware & Tools – wrenches, sockets, durable hand tools.

– Electronics – copper and aluminum cold forged parts for connectors and terminals.

– Fastening Systems – wing nuts, commonly used in equipment, machinery, and structural assemblies where frequent adjustments or hand tightening is required.

At Weforging, we supply custom forgings ranging from 0.05 kg to 150 kg, serving industries such as engineering machinery, mining equipment, wind power, aerospace, high-speed rail, and bridges.

See real customer projects:Forged Cases

Forging: Cold vs Hot

Criteria | Cold Forging | |

Temperature | Room or near-room temperature | Above recrystallization temp |

Accuracy & Finish | High precision, smooth surface | Lower, needs machining |

Material Utilization | High, minimal waste | Medium, flash and scrap common |

Mechanical Properties | Stronger, harder, work-hardened | Ductile, better elongation |

Cost | Higher die cost, lower energy | Lower die cost, higher energy |

Conclusion

Cold forging is a proven metal forming process that delivers strong, precise, and cost-effective results. From everyday fasteners to aerospace components, cold forged parts remain essential across industries. With growing demand for sustainability and high-performance manufacturing, the scope of cold forging applications and innovative forging techniques will only continue to expand.

As a leading exporter of forged products, Weforging Manufacturing is committed not just to manufacturing, but to acting as your product manager—helping you reduce costs while delivering superior quality.

F.A.Q.

Cold forging increases surface hardness through work hardening, making it ideal for high-strength small components. Hot forging provides better internal ductility and impact resistance, suitable for larger or complex parts.

Cold forging delivers high dimensional accuracy and near-net-shape results with minimal machining. Hot forging can form complex shapes but generally needs more machining due to thermal expansion.

U.S. OEMs outsource cold forging to lower tooling and production costs, shorten lead times, and work with suppliers offering integrated forging, CNC machining, heat treatment, and testing.