What Is Forging? A Complete Guide to Metal Forging Processes

Forging is one of the oldest metal forming processes, used for centuries to create strong and durable components. But what is forging, and why does it remain vital for industries needing performance and reliability? To define forging simply, it’s shaping metal with localized compressive forces, producing components with excellent mechanical properties.

In today’s industry, forging engineering has advanced significantly. By combining traditional expertise with CNC machining and modern hydraulic presses, manufacturers deliver precise and consistent parts. These capabilities support critical applications in automotive, energy, heavy equipment. This article explains the forging manufacturing process, introduces major forging methods, and highlights the benefits of hot forging and cold forging.

Define Forging – Understanding the Basics

To define forging is to describe the process of shaping heated metal by mechanical force, whether through hammering, pressing, or rolling. Unlike casting, where molten metal is poured into molds, forging deforms solid metal to improve its internal structure and performance.

The forging metal definition emphasizes durability: the grain structure is refined, voids are eliminated, and fatigue resistance is enhanced. As a result, forged parts are used in demanding applications such as gears and shafts, flanges, and fasteners.

Forging Engineering Principles

Forging engineering combines material science and mechanical principles to optimize how metal responds to pressure and heat. By carefully managing temperature, applied force, and deformation speed, manufacturers can produce components with excellent hardness, toughness, and long-term fatigue resistance.

For example, forged steel offers consistent performance and enhanced structural integrity, making it highly suitable for demanding applications. This strength and reliability are key reasons why industries such as automotive transmissions, aerospace systems, and energy equipment rely on forged parts as a foundation for safe and efficient operation.

The Forging Manufacturing Process

The forging manufacturing process includes four key stages that ensure strength, precision, and reliability in every forged part.

Heating – The metal is raised to the ideal temperature, making it malleable and prepared for accurate shaping.

Forming – Hydraulic presses or precision hammers apply controlled force to shape the metal into the required geometry.

Trimming and Cooling – Material is refined, and the component is cooled under controlled conditions to enhance structural integrity.

Finishing – With precision machining, surface treatment, and inspection, the forged part achieves required accuracy and performance.

Forging Methods and Applications

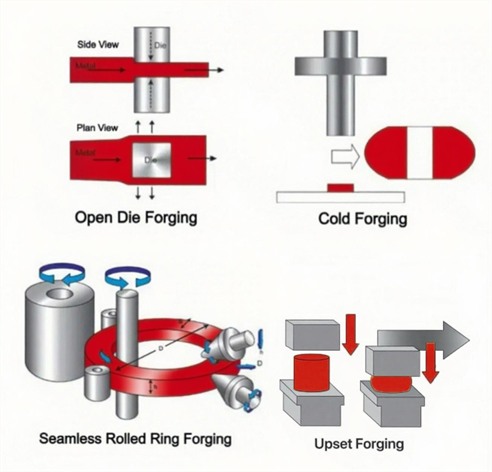

Several forging methods are commonly used:

– Open Die Forging – for large shafts and blocks.

– Closed Die Forging – for precision automotive and aerospace parts.

– Rolled Ring Forging bearings and gear rings.

– Upset Forging – for bolts, nuts, and flanges.

Each method offers advantages depending on the required strength, geometry, and production volume. Forged gear shafts and flanges, for example, provide higher reliability and longer service life than parts produced by casting or welding.

Forging Processes Based on Temperature

Forging processes are commonly classified based on forming temperature, which directly influences material flow behavior, dimensional accuracy, tooling load, and downstream machining requirements. Selecting the appropriate temperature range allows manufacturers to balance performance, cost, and production efficiency.

Hot forging is performed above the material’s recrystallization temperature, enabling excellent plasticity and grain flow control. It is widely used for large or complex components where shape flexibility and internal structural integrity are priorities.

Warm forging operates at intermediate temperatures, offering a compromise between forming force and dimensional precision. This process is often selected for parts requiring improved accuracy while maintaining reasonable deformation capability.

Cold forging is carried out near room temperature and is typically applied to smaller components produced in high volumes. It delivers superior surface finish, dimensional consistency, and material utilization, making it suitable for precision parts and fasteners.

By evaluating temperature effects early, OEMs can align forging processes with component geometry, performance requirements, and total manufacturing cost.

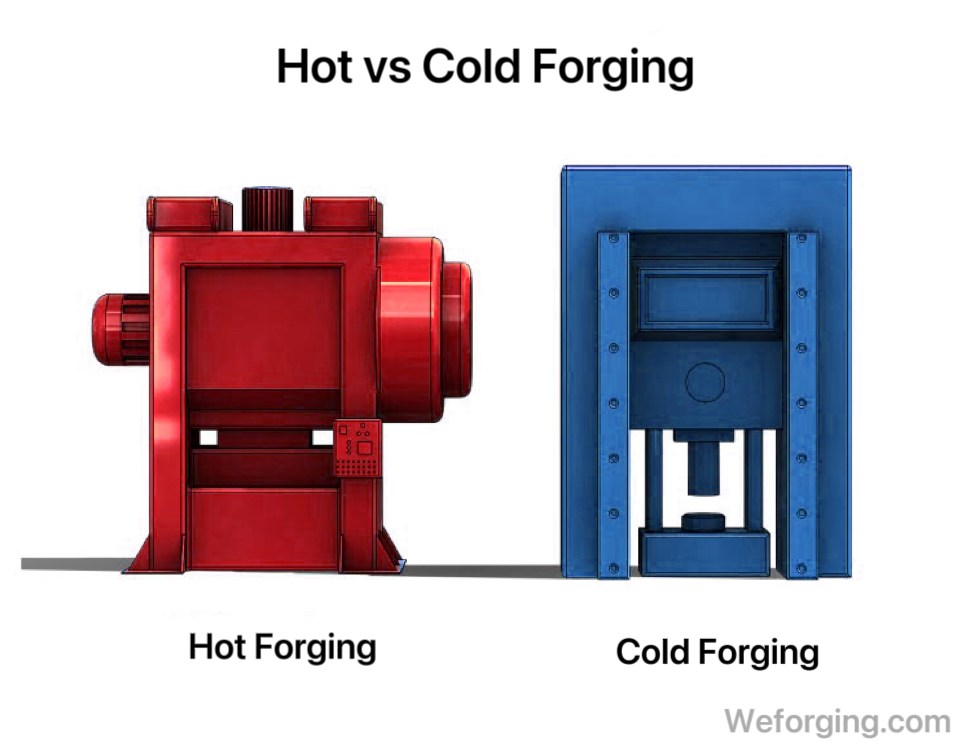

Hot Forging vs. Cold Forging

A key distinction in forging methods is whether the process occurs at high or low temperatures. Hot forging heats metal above its recrystallization point, making it malleable and easier to shape. This method is widely applied for flanges, gear shafts, and heavy-duty fasteners, as high temperatures enhance ductility and allow complex geometries.

By contrast, cold forging takes place at or near room temperature. It delivers smoother surface finishes, greater dimensional accuracy, and increased strength through strain hardening. As a result, cold forging is ideal for smaller components like nuts and bolts, bushings, and precision automotive parts where accuracy is essential.

Ultimately, the choice between hot forging and cold forging depends on material type, tolerance needs, and production volume. In many industries, manufacturers combine both methods with machining to achieve the best balance of strength, accuracy, and efficiency.

Forging Metal Process in Modern Industry

The forging metal process continues to be central in industries that require durability and safety. While casting remains useful for certain designs, forging ensures a stronger grain structure and greater resistance to impact and fatigue.

With the addition of CNC machining, forged parts achieve both structural integrity and precise tolerances, making them essential for critical applications across automotive, marine, aerospace, and heavy equipment manufacturing.For reference, industry guidelines can be found in forging standards published by ASM International.

Conclusion

Forging is a vital process in modern metalworking, valued for strength, accuracy, and reliability. To define forging is to describe shaping heated metal with controlled compressive forces. Forging engineering applies material science to optimize performance and ensure durable components. The forging manufacturing process covers heating, forming, cooling, and finishing for consistent quality. Different forging methods, including hot forging and cold forging, provide tailored advantages for today’s industries.

At Weforging, we integrate advanced forging technology, CNC machining, and strict quality testing to provide dependable solutions for global buyers. Whether you require standard designs or customized specifications, our team is ready to support your project needs.

Contact us today to discuss your requirements or request a quote.

F.A.Q.

Forging involves shaping solid metal by applying mechanical force, resulting in stronger components with superior mechanical properties. Casting, on the other hand, involves melting the metal and pouring it into molds to form shapes. Forged parts generally have higher density and better mechanical properties, making them ideal for high-performance applications.

Common forging materials include:

Carbon Steel: Grades like 1000, 1100, 1200, and 1500 series.

Alloy Steel: Grades such as 4000 to 9000 series.

Stainless Steel: Including 300 and 400 series, and PH grades like 13.8, 15.5, and 17.4.

Aluminum Alloys: Grades such as 2000, 6000, and 7000 series.

Forged parts offer several advantages:

High Strength and Durability: Forging improves the grain structure of the metal, enhancing its tensile strength and fatigue life.

Superior Mechanical Properties: The deformation process eliminates casting defects, such as porosity and inclusions, leading to stronger, more reliable parts.

Reliability: Ideal for critical applications in industries such as automotive, aerospace, energy, and heavy machinery.