What are CNC and NC?

In-depth research on the precision manufacturing and high-quality forging solutions in the forging industry, combined with precise CNC processing, promotes the continuous upgrading of modern industry. These comprehensive capabilities enable us to meet the increasingly complex demands of modern manufacturing. But what exactly is CNC? In this comprehensive guide, we explore the history, technology, applications and advantages of CNC, especially the significance and background of why it is necessary to discuss CNC in the context of the forging industry.

What are CNC and NC?

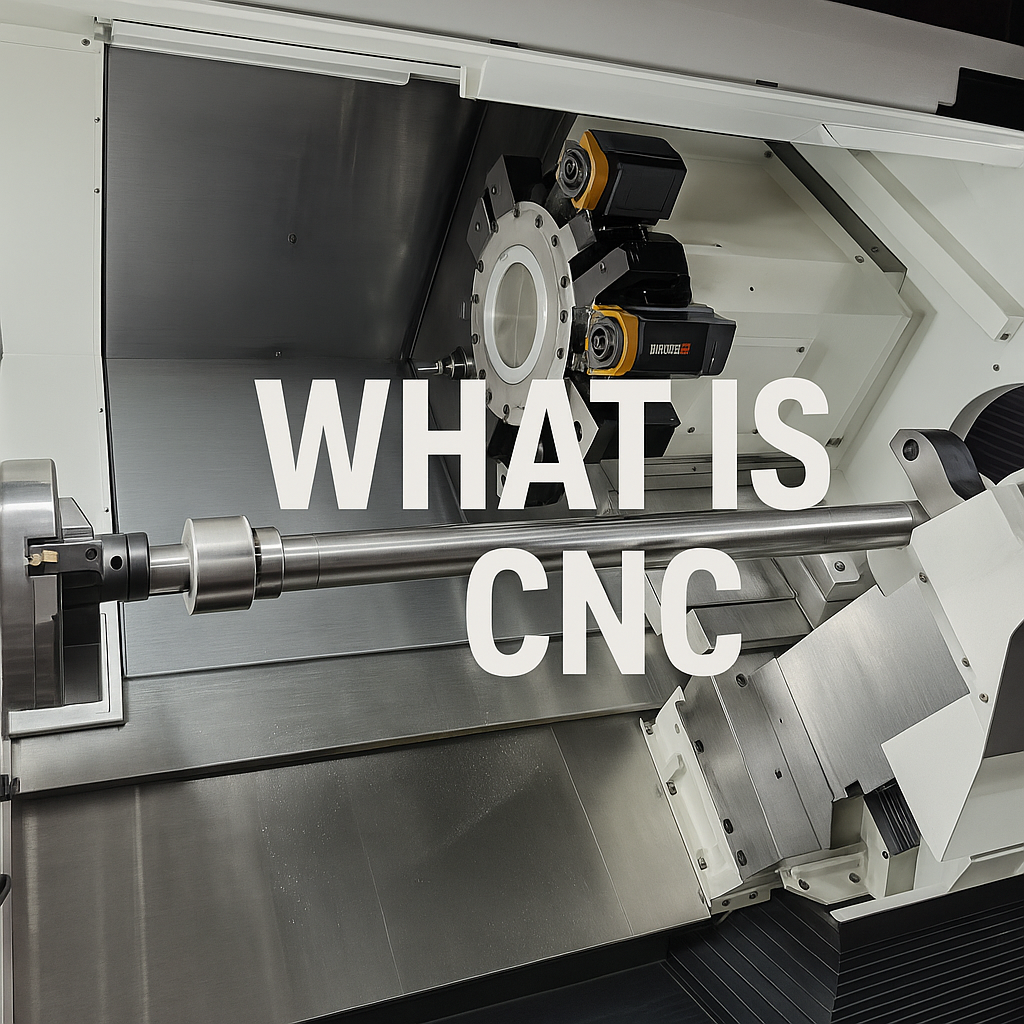

CNC and NC are both forms of equipment combined with computer numerical control, which utilize computers to automatically control processing tools. CNC machine tools parse digital files and use them to precisely control the speed, cutting volume, tool movement, and spindle movement. These machines are indispensable when manufacturing parts that require strict tolerances and repeatable precision. Unlike manual processing, CNC machine tools operate automatically once programmed, minimizing the possibility of human error and relatively ensuring the consistency and stability of batch products.

CNC enables companies like Weforging to produce complex, high-precision parts on a large scale with high efficiency, providing traceability of CNC products from the source of materials and forging. The coordination of the entire process, from forging, inspection, CNC turning, CNC milling services to CNC grinding machines and CNC gear hobbing and shaping, ultimately leads to the high reliability of the product. We offer tailor-made solutions to meet strict industrial standards.

The Development of Numerical Control Technology in Manufacturing Industry

The concept of CNC can be traced back to the 1940s, when early numerical control (NC) machine tools were developed. These machines were originally controlled by perforated paper tapes. In the 1970s, the development of microprocessors led to the birth of modern CNC machine tools. Today, CNC technology encompasses the integration of CAD/CAM software, human-machine dialogue, real-time monitoring, and the automation of linked production across multiple axes and multiple devices.

Integrating CNC into the forging workflow adds incredible value. Forged components have inherent strength and yield toughness due to the alignment of their grain structure, and when paired with CNC machining, they meet precise geometric and surface finish requirements. For instance, our CNC milling processing technology enables us to process complex features into forged blanks with minimal material waste.

Comparison between Numerical Control and Traditional Processing

In traditional mechanical processing, the operator manually relies on experience to perform various operations such as swinging and rotating the equipment to achieve the cutting of the workpiece. In contrast, CNC machining uses programming instructions to precisely and consistently guide the tool to work in coordination with the spindle and tool rest, thereby achieving processes such as turning, milling, and drilling.

The advantages of numerical control machining over manual machining include:

- Greater accuracy, high repeat positioning precision, and high batch stability

- High repeatability, simple operation, and reduced human factors

- Faster production speed, reduced labor costs, and the ability to handle complex geometries

Our milling operation is a typical example of how CNC improves traditional methods, providing outstanding results while shortening delivery times.

Key Types of Numerical Control Machining

- CNC Milling: Also known as machining center equipment, CNC milling involves using a rotating multi-point cutting tool to remove material from a workpiece. This process is ideal for producing complex shapes and with strict tolerances. We offer 5-axis CNC milling services for forgings and raw materials.

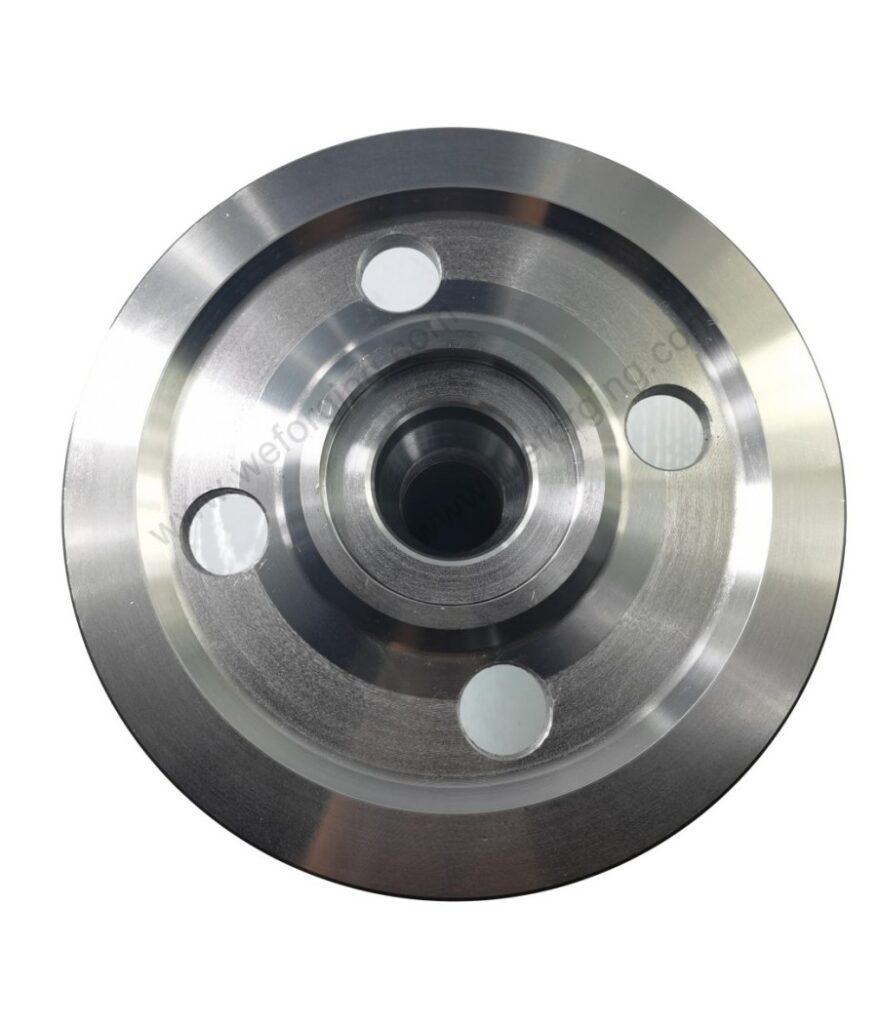

- CNC Turning: In CNC turning, the workpiece can rotate while the tool remains stationary, or the workpiece can remain stationary while the tool rotates. This process is typically used for cylindrical parts, such as shafts and bushings.

- CNC drilling: CNC drilling offers accurate and efficient hole-making capabilities. It is often used in combination with milling and turning for the production of multi-functional parts.

- CNC Grinding: The precision processing by grinding machines enhances the flatness, surface finish and dimensional accuracy of parts. When the workpiece components need to rotate at high speeds, it becomes particularly important. In applications, the high precision of bearing positions and bearings is a common application scenario, and this process is indispensable.

- CNC Gear hobbing and Shaping: Gears are crucial in the transmission of various machinery. The precision and strength (forging) of gears determine their lifespan and the noise of the equipment. The precision of gears requires high-precision gear grinding machines and grinding wheels.

The manufacturing technology of each process directly affects the reliable performance of the product, so CNC equipment plays a crucial role in the manufacturing field.

CNC in the Forging Industry

Forging endows the workpiece with strength, while CNC endows the product with precision. By combining the two, manufacturers can provide parts that meet structural and dimensional requirements.

Our CNC machining capabilities complement our forging expertise:Processing complex post-forging features, large-scale operations with strict tolerances, part serialization and customization.

Our online platform for CNC milling parts enables customers to quickly and effectively configure and order custom-processed forged components.

Our Processing Materials:We also offer surface treatment for forged or machined materials such as carbon steel, gear steel, alloy steel, stainless steel, and aluminum alloy, which are particularly popular in industries that require corrosion resistance and high strength.

Our Service Industry:Our CNC and forging services cater to a wide range of industries.

Gearbox: Gear shaft, shaft gear, gear ring, connecting flange and anti-loosening fastener

Construction machinery: gearbox gear parts, gearboxes, car transmission components.

Hydraulic cylinder: rod head, ear ring, piston rod, cylinder bottom, cylinder head, flange, cylinder head, cylinder barrel, nylon nut, etc.

Agricultural and forestry equipment: processing of all mechanical parts and assemblies such as swing discs, flanges, structural components, etc.

Oil and gas: Valve components, pump components, flow control valve bodies.

Medical: Forged and machined parts of stainless steel.

We offer tailor-made solutions, such as CNC milling of metals, to meet the specific needs of each industry.

Advantages of CNC MACHINING in Weforging

Customized solutions: from prototype design to forging to CNC, one chain traceability, quality control, laboratory enhanced, flaw detection equipment……

Three-coordinate precise measurement: Under a certain temperature control, ensure the consistency of measurement standards

Quick response: Our mission is to solve customers’ problems and provide them with technical and manufacturing solutions

End-to-end service: from forgings to finished products

We are committed to providing high-quality and reliable components to help our customers stand out in their markets. If you have any technical questions about CNC and other processes, you can consult our technical team:

- Web:www.weforging.com

- Email:[email protected]