Weforging creates precision gears for high-end European cruise ships to drive a new future of ocean navigation

The precision gear solution from

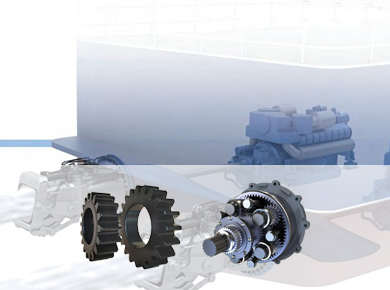

Weforging is quietly operating in the gear ring gearbox of the electric actuator, an advanced flow control system component for high-end European cruise ships and ships. Weforging brings key components with high precision, high strength and excellent corrosion resistance to Marine navigation equipment through its excellent forging and machining processes.

In forging process,

♦Weforging adopts advanced

hot die forging technology. Under precisely controlled high temperature and high pressure environment, the raw material is repeatedly forged to make the grain structure inside the metal more dense and uniform, giving the gear excellent strength and toughness. This unique forging method allows the gear ring, gear and other parts to maintain stable operating accuracy when subjected to huge torque, to avoid affecting the performance of the entire flow control system due to stress deformation.

♦The machining process

also demonstrates the high skill of Weforging. Using high precision CNC gear shaper machine, MAzak processing equipment, with experienced technical team, the forged gear billet is fine processed. From precision gear shaper to precision turning of shaft components, every process is strictly in accordance with micron level accuracy standards. Through precision processing technology, ensure that the meshing accuracy between the gear ring and the gear reaches the extreme, greatly reduce the noise and vibration during the operation, and provide a strong guarantee for the smooth operation of the cruise ship and the ship.

The gear solutions offered by Weforging have been successfully applied to several high-end European cruise ships and ships.

♦In actual sea navigation,

these precision gears drive the flow control system stably with their high precision and high strength, ensuring that the ship can accurately control the flow and air flow in various sea conditions. Excellent corrosion resistance also makes the gear in the long-term offshore operation, always maintain good performance state, won the customer’s high praise.

The head of Weforging said:

“It is our pleasure to

provide key gear components for the high-end cruise and Marine industry in Europe, and it is also a recognition of the company’s technical strength. In the future, we will continue to innovate and continuously improve the technological level, provide more high-quality and reliable products for the global navigation industry, and help the Marine navigation equipment to move towards a higher performance era.” With the continuous deepening of Weforging in the field of Marine equipment parts manufacturing, we believe that it will bring more technological breakthroughs and reliable guarantee for the Marine transportation and cruise ship industry.