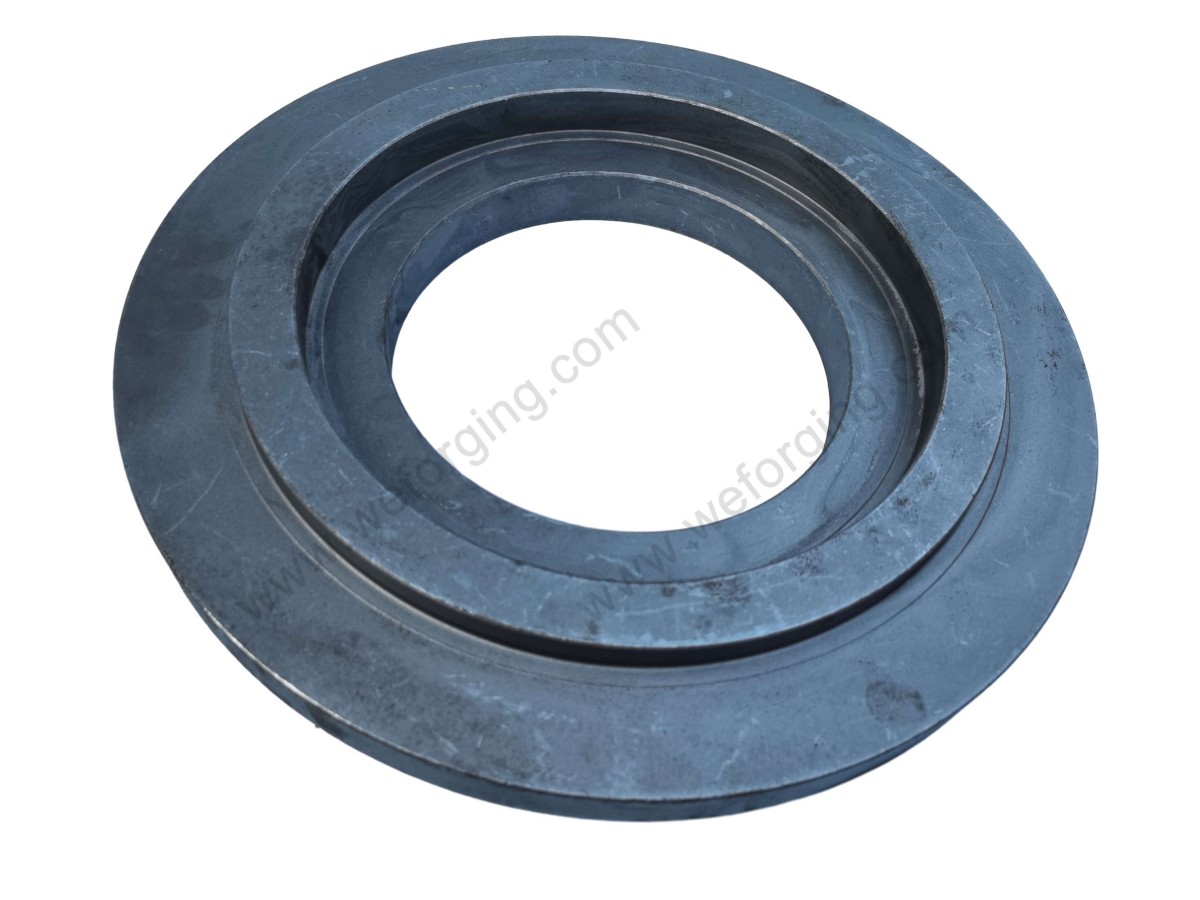

Premium Custom Ring Forgings for Industrial Applications

Our custom ring forgings are precision-engineered components designed to meet the most demanding requirements across various industries. Manufactured through advanced forging processes using high-quality alloy steels, stainless steels, or specialty metals, these ring forgings offer superior mechanical properties and exceptional durability. Available in diameters ranging from 100mm to 5000mm, our ring forgings undergo strict quality control including ultrasonic testing and dimensional verification to ensure perfect fit and performance.

The forged rings feature excellent grain flow characteristics that enhance strength and fatigue resistance, making them ideal for critical applications in aerospace, energy, and heavy machinery sectors. We offer multiple material options including carbon steel (ASTM A105), alloy steel (AISI 4140/4340), and stainless steel (304/316), with optional heat treatment processes to achieve desired hardness levels up to HRC 58. Customization options include various wall thicknesses, surface finishes (machined, ground, or as-forged), and special coatings for corrosion protection.

Our ring forgings comply with international standards such as ASTM, DIN, and ISO, and are widely used in bearing assemblies, gear blanks, flanges, and pressure vessel components. With CNC machining capabilities, we can provide finished ring components ready for installation, reducing your production lead times. Typical applications include wind turbine hubs, mining equipment rings, and marine propulsion system components.

Key advantages include:

- Superior strength-to-weight ratio compared to cast alternatives

- Consistent material properties throughout the component

- Cost-effective solution for high-volume production

- Reduced machining requirements due to near-net shape

- Full material traceability and certification

Αξιολογήσεις

Δεν υπάρχει καμία αξιολόγηση ακόμη.