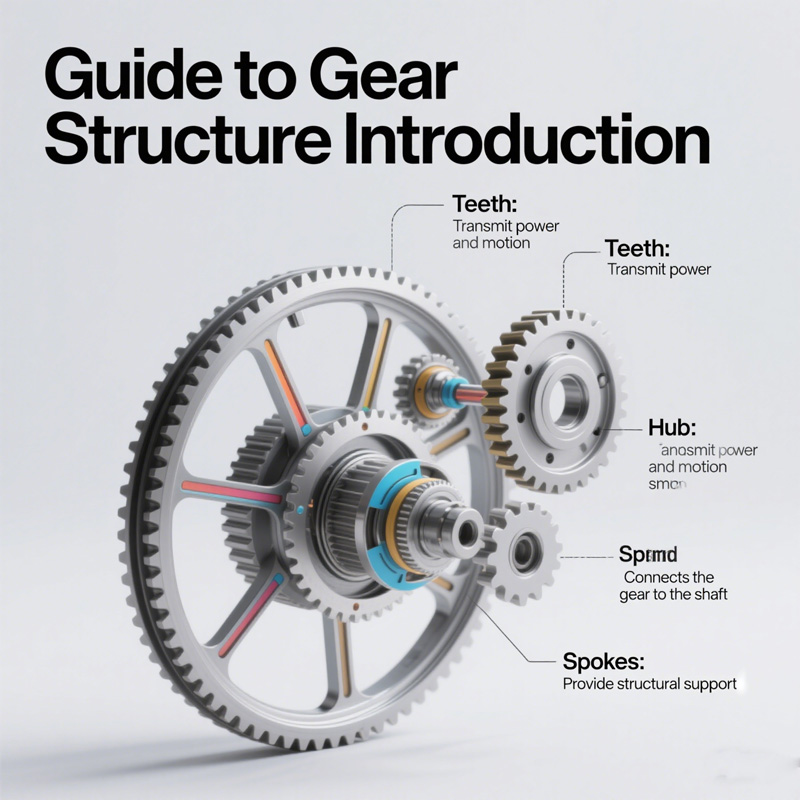

1.Introduction to Gears

♠♠♠Gears are core mechanical components that transmit torque and motion between rotating shafts and are widely used in fields such as automobiles, aerospace, manufacturing, and robotics. Depending on the type – such as internal gears, external gear rings, spur gears, helical gears, bevel gears and worm gears – each type of gear plays a unique role in the power transmission system.

♠♠♠High-quality gear manufacturing, including the forging gear process, makes its strength and durability far exceed those of traditional machined gears after forging. This article will conduct an in-depth analysis of gear types, application scenarios, and the industrial advantages of forged gears.

2.Gear Types and Their Application Scenarios

2.1 Internal Gear

¤¤¤ Structural characteristics

The tooth profile is distributed on the inner side of the ring and meshes in the opposite direction with the standard external gear. Usually, an involute tooth profile design is adopted

Planetary gearbox (coordination between the sun gear and the internal gear ring)

Slewing bearing system (Construction machinery turntable drive)

Hydraulic motor (cycloidal gear pair)

Aerospace (Helicopter transmission system)

2.2 External Ring Gear

¤¤¤ Structural characteristics

The tooth profile is distributed on the outside of the ring and can be regarded as an extra-large diameter external gear, often used in conjunction with multiple planetary gears

Wind power gearbox (main drive for megawatt-level units)

Shield machine drive (high-torque tunnel boring equipment)

Ship thrusters (low-speed heavy-load transmission system)

Mining machinery (gearbox gear transmission ring)

2.3 Straight Gear

¤¤¤ Spur gears have the simplest and most common structure, with the tooth lines parallel to the gear axis. They are suitable for high-speed and low-torque scenarios, such as:

Conveyor belt system

Electric motor

Washing machine

2.4 Helical Gear

¤¤¤ The tooth lines of helical gears are at a helical Angle, making their operation smoother and quieter. Typical applications include:

Automobile transmission

Heavy machinery

Power plant equipment

2.5 Bevel Gear

¤¤¤ Bevel gears are conical and are used for power transmission between intersecting shafts. They are commonly found in:

Automobile differential

Electric drill

Ship propulsion system

2.6 Worm gear and worm

¤¤¤ Worm gear is composed of a screw-shaped worm and paired gears, featuring a high reduction ratio and self-locking characteristics. It is widely used in:

Flow control valve

Conveying system

Heavy lifting equipment

For high performance gears, WeForging can provide precision forged gears with superior mechanical properties.

3.Gear Manufacturing Process: Machining vs Forging

3.1 Machined gears

¤¤¤ Traditional gears are formed through CNC cutting or gear hobbing processing. Although they are suitable for small-batch production, the grain structure strength of the materials is relatively weak.

3.2 Forged Gears

¤¤¤ Gear forging optimizes the flow direction of metal grains through high-pressure forming, significantly enhancing performance. Its advantages include:

Higher load-bearing capacity – Forged gears can withstand extreme stress

Longer service life – Dense structure reduces wear and fatigue

Superior performance – suitable for heavy-duty scenarios such as mining and oil drilling

Understanding the functions of forged gear blanks, the closed-die forging process is adopted to produce high-strength gears. Its forged gear solution has been applied in the industrial machinery field with high load and heavy load.

Why choose forged gears?

¤¤¤ Outstanding strength and durability

The forging process enables the directional arrangement of metal grains, significantly enhancing the impact resistance.

¤¤¤ Mass production is more cost-effective

Although the cost of molds is relatively high, large-scale production can reduce material waste and the overall cost is lower.

¤¤¤ Highly customized

We offer custom forged gears of various materials, including:

Carbon steel, alloy steel, stainless steel

The core industry that relies on high-quality gears

- Automotive industry

Precision gears are required for the transmission, differential and steering system.

- Aerospace and National Defense

Forged gears ensure the reliability of aircraft engines and military vehicles.

- Heavy machinery

Mining, construction and oilfield equipment requires highly durable forged gears to ensure long-term operation.

- Renewable energy

Wind turbines and hydropower stations rely on large gears to efficiently convert kinetic energy.

For high-performance gear solutions, custom forging services are available at WeForging.

4.How to choose a gear supplier

Choosing a reliable manufacturer is crucial for the performance and lifespan of gears. Whether you need to machine or forge gears, you need to comprehensively consider the material, precision and application requirements.

Youdaoplaceholder0 combines advanced forging techniques with decades of experience to provide high-strength precision gears for harsh conditions. Contact us immediately for a free quote!

Email: [email protected]