Guide to Industrial Fasteners: Detailed Explanation of the Functions and Applications of Nuts and Bolts

Introduction

In manufacturing and industrial applications, nuts and bolts are the most fundamental yet crucial fasteners because screws connect everything. They are widely used in fields such as mechanical assembly, building structures, and assembly connections. This article will introduce in detail the types, functions, material selection of nuts and bolts and how to use them correctly, helping customers better understand the importance of these fasteners and select or customize nuts and bolts that meet their own needs based on the requirements of cost, strength and application scenarios.

1. What are Nuts and Bolts?

♠Nuts and bolts are the basic components of mechanical fasteners and are used to firmly connect two or more parts together..

♠A bolt is a fastener with external threads, usually used in conjunction with a nut. A nut is a part with internal threads that can be tightened onto a bolt.

♠Together with an anti-loosening washer, they form a stable connection structure.

2.Main Components:

♠Bolt: A rod-shaped part with threads, usually with a hexagonal or round head at one end, which is convenient for tightening with tools.

♠Nut: An internal thread part, used in conjunction with a bolt to provide fastening force.

♠Washer (optional) : It is used to disperse pressure and prevent loosening or damage to the connected surfaces.

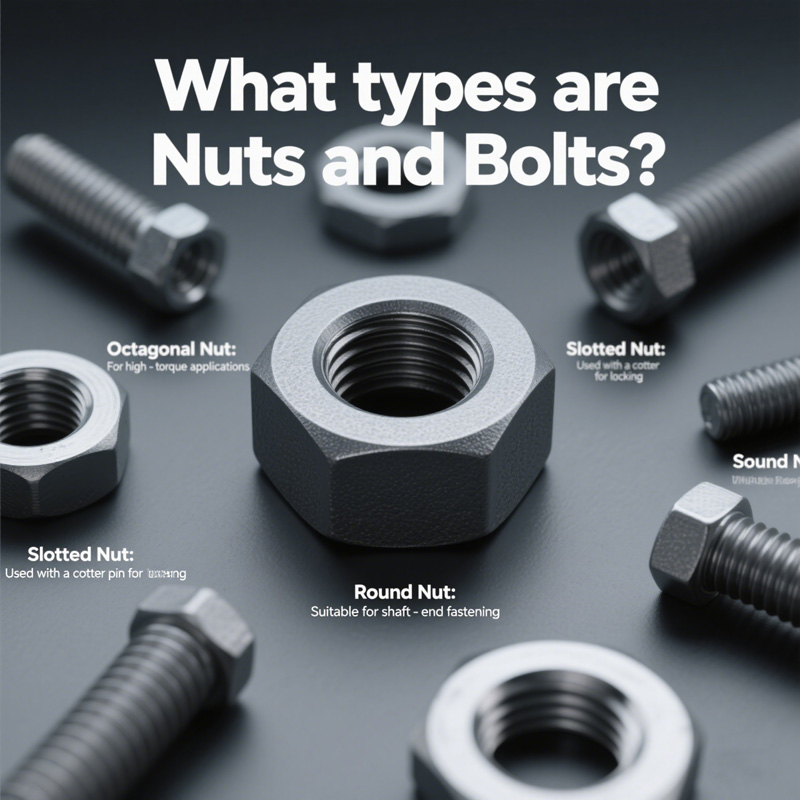

3.Main Types of Nuts and Bolts

3.1 Types of Bolts

a) Hex Bolt

Ξ Features: Hexagonal head design, suitable for tightening with a wrench or socket.

Application: Industrial flange connection, construction, mechanical assembly, heavy equipment.

Manufacturing process: Mainly cold forging process

b) Socket Head Cap Screw

Ξ Features: Cylindrical head, internal hexagonal hole, suitable for space-constrained environments.

Application: Precision machinery, electronic equipment, automotive parts.

Manufacturing process: Mainly cold forging or hot forging processes are adopted

c) Flange Bolt

Ξ Features:

Equipped with an integrated gasket, providing better anti-loosening performance; Some of the structures are equipped with toothed structures to ensure that the loosening is limited to a certain range.

Applications: Pipe connections, automotive parts, mining safety.

Manufacturing process: Mainly through specialized equipment and machining

3.2 Types of Nuts

- a) Hex Nut

Features: Standard hexagonal shape, suitable for most bolts.

Application: General fastening requirements.

Manufacturing process: Mainly hot forging

- b) Nylon Insert Lock Nut

Features: Built-in nylon ring to prevent loosening.

Application: High-vibration environments, such as high-pressure oil cylinders and aviation.

Manufacturing process: Hot forging + machining + injection molding

- c) Flange Nut

Features: Equipped with a wide flange to increase the contact area and reduce the risk of loosening.

Application: Situations where additional stability is required.

Manufacturing process: Cold extrusion direct forming

- c) Customized large nuts (Flange Nut)

Feature: Special environment. For instance, Bridges that require non-standard and special structural requirements.

Application: Special strength requirements for Bridges or specialized equipment, nuclear power, etc

Manufacturing process: Hot forging + heat treatment + flaw detection and anti-corrosion

4.Material Selection of Nuts and Bolts

⊆ Different application environments require fasteners of different materials. The following are common material options:

4.1 Carbon Steel

Advantages: High strength, economical and cost-effective, low cost

Applicable environment: Common industrial uses and fields with low cost requirements.

4.2 Stainless Steel

Advantages: Corrosion-resistant, suitable for humid or chemical environments.

Applicable environments: Food processing, Marine engineering, outdoor construction.

4.3 Alloy Steel

Advantages: Ultra-high strength, suitable for heavy-load applications.

Applicable environments: Mine safety, aerospace, heavy machinery.

4.4 Brass/Copper Alloy

Advantages: Good electrical conductivity and corrosion resistance.

Applicable environment: Electrical equipment, decorative applications.

5.Hardness Grade Standards for Nuts/Bolts Different countries and regions adopt different standards. The following are the main classifications:

5.1 SAE Standard (Society of Automotive Engineers)

It is mainly used for American-made bolts and is indicated by “Grade”, such as Grade 2, Grade 5, Grade 8.

SAE grade tensile strength (MPa) and yield strength (MPa) are commonly applied

Grade 2 400-550 250 Low-strength general-purpose bolts (for lightweight structures)

Grade 5 800-900 650 Moderate strength (Automotive, Mechanical)

Grade 8 1,200-1,500 1,000 High strength (aerospace, heavy-duty equipment)

Identification method: The head of the bolt usually has concave point marks (such as Grade 5 = 3 lines, Grade 8 = 6 lines).

5.2 ISO Standards (International Organization for Standardization)

Adopt “Property Class” (performance level), such as 4.6, 8.8, 10.9, 12.9.

Common applications of ISO grade tensile strength (MPa) and yield strength (MPa)

4.6 400 240 General low-strength bolts

8.8 800 640 Medium strength (Construction, Machinery)

10.9 1,000 900 High intensity (automobiles, heavy industry)

12.9 1,200 1,080 Ultra-high strength (Aerospace, racing)

6.How to correctly Select and Use Nuts and Bolts?

6.1 Determine the load requirements

For light-load applications (such as small machinery), ordinary carbon steel bolts can be used.

In heavy-duty or vibrating environments (such as excavators), high-strength or anti-loosening nuts should be selected.

6.2 Consider environmental factors

It is recommended to use stainless steel or galvanized bolts in outdoor or humid environments.

Heat-resistant alloy materials should be selected for high-temperature environments.

6.3 Correct Installation method

Use a torque wrench to ensure an appropriate tightening force and avoid being too tight or too loose.

In a vibrating environment, it is recommended to use lock washers or nylon lock nuts.

6.4 Regular maintenance and inspection

Bolts that have been in use for a long time may become loose or corroded and need to be inspected and replaced regularly.

Vii. Why Choose Our Nuts and Bolts?

As a professional manufacturer of anti-loosening nuts, we offer:

✔ 40 years of focus: Nylon anti-loosening nuts and double-laminated self-locking washers, widely used in high-demand applications such as high-speed railways.

✔ High-quality materials: Steel and alloys that comply with international standards (ISO, DIN, ASTM) are adopted.

✔ Diverse options: Covering various sizes, thread types and surface treatments (galvanized, Dacromet, etc.).

✔ Customized service: Special specification fasteners can be provided according to customer requirements.

✔ Global supply: Support rapid delivery to the European and American markets to ensure the stability of the supply chain.

7.Conclusion

Although Nuts and bolts seem simple, they play a crucial role in industrial manufacturing. Choosing the right fasteners not only enhances assembly efficiency but also ensures the safety and reliability of long-term use. If you are looking for high-quality industrial nuts and bolts. Get your exclusive gear solution!

Email:[email protected]