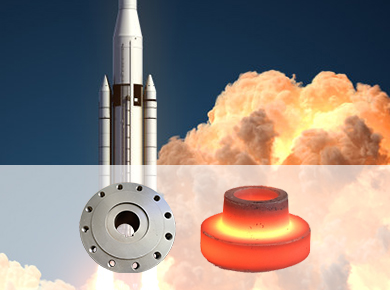

Weforging case scenario for manufacturing space rocket coupling components for MTU

In the demanding aerospace sector, high-performance rocket coupling components are critical for mission success. MTU Aerospace, a leader in space propulsion systems, relies on precision-forged couplings that meet the most stringent aerospace quality standards.

As a trusted MTU supplier, Weforging delivers mission-critical rocket components engineered for unmatched strength, durability, and reliability. Our advanced forging technology ensures optimal performance in extreme conditions, supporting successful space launches.

Through high-strength materials, precision manufacturing, and rigorous testing, Weforging produces aerospace-grade couplings that outperform industry standards. This partnership with MTU Aerospace highlights our leadership in space technology innovation and cements our position as a premier aerospace forging solutions provider.

Advantages of Weforging

Advanced Manufacturing for Superior Rocket Coupling Components

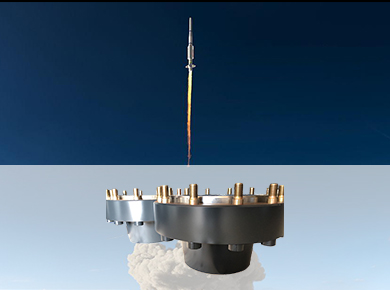

Weforging utilizes advanced forging processes to optimize component performance. Our hot die forging technology significantly increases material density. Consequently, parts maintain exceptional stability under extreme pressure conditions.

Moreover, we achieve the perfect strength-toughness balance through precision engineering. Every coupling component undergoes rigorous quality verification. This ensures reliable performance in critical aerospace applications.

Uncompromising Quality Control Standards

From raw material procurement, we implement strict screening protocols. Additionally, high-precision testing equipment monitors each production stage. Specifically, we verify dimensional accuracy and detect potential defects.

For instance, ultrasonic flaw detectors identify microscopic cracks immediately. Therefore, we guarantee flawless final products. Our comprehensive quality system exceeds aerospace industry requirements.

Project implementation process

Design collaboration:Communicate closely with MTU in Weforging to gain an in-depth understanding of the specific use scenarios and performance indicators of the coupling components in the rocket system. According to these requirements, the research and development team in Weforging conducts targeted design and determines the final design through multiple simulation analysis and optimization.

Manufacturing: In strict accordance with the design scheme and process requirements, put into advanced production equipment for manufacturing. In the forging process, precise control of temperature, pressure and forging ratio; In the machining process, high-precision machine tools are used to ensure the dimensional accuracy of components.

Quality inspection: Complete the manufacturing of the coupling parts, after multiple rounds of comprehensive inspection. In addition to conventional size and hardness testing, performance tests are also carried out to simulate the rocket launch environment to ensure that the components meet the performance standards under extreme conditions.

Outcomes of cooperation

Weforging’s high-performance space rocket coupling components fully comply with MTU’s stringent technical requirements, meeting all critical performance indicators with exceptional precision. These aerospace-grade coupling parts have demonstrated outstanding reliability in practical applications, ensuring stable operation and mission success for rocket propulsion systems. Through rigorous quality control and advanced forging technology, Weforging delivers MTU-approved components that exceed industry standards for durability and performance in extreme space environments.

Weforging’s proven manufacturing capabilities have earned MTU’s strong recognition. This successful partnership establishes a solid foundation for future collaboration. Both parties plan to expand cooperation on more space projects. The alliance strengthens Weforging’s position in aerospace component manufacturing. Long-term cooperation will drive innovation in space technology solutions.