Ne Yapıyoruz

One-stop forging customized and machining

Weforging Manufacturing is a leading expert in forging production, specializing in providing customized forging products and services for multiple industrial sectors. Our solutions are widely applied in high-end manufacturing fields including construction and mining machinery, agricultural and forestry equipment, bridge and rail engineering, wind power and transmission hydraulic systems, as well as aerospace applications.

In the field of hot die forging and cold extrusion, Weforging strives to provide a one-stop solution from design/standard process establishment to final delivery. With 42 years of experience in forging, we ensure the precision and quality level of forging parts, forging and precision machining in strict accordance with drawings and related technical requirements.

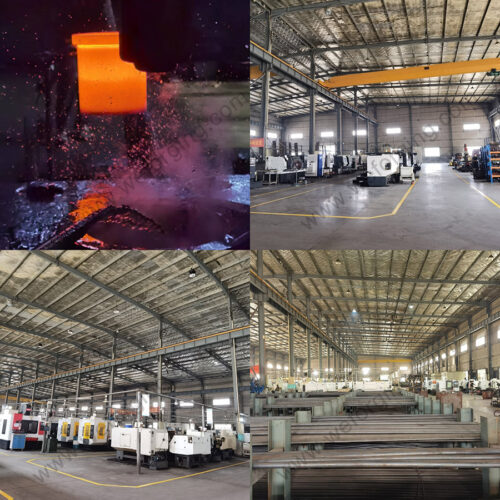

Hot forging & Machining production process

We operate large-scale forging presses, Mazak CNC machining centers, and coordinate measuring machines, supported by rigorous material testing in our in-house laboratory. This integrated manufacturing system ensures precise control from material formulation to die design and process optimization, delivering forged components with exceptional mechanical properties and dimensional accuracy. Our technological leadership spans hot die forging, cold extrusion, gear rings, and fasteners.

Our advantages

Advantages of hot forging and cold extrusion:

Weforging'de, müşterinin dövme ve işleme teknik parametre gereksinimlerini kesinlikle takip ediyoruz. Dövme kalıbı tasarımından metal şekillendirme, ısıl işlem ve hassas işleme sürecine kadar, sıkı süreç teknik rehberlik belgelerimiz ve bir laboratuvarımız var. Mükemmelliğe olan bağlılığımız dövme işleminin tüm yönlerini kapsamaktadır. Hem sıcak kalıp dövmede hem de soğuk dövmede bariz avantajları vardır.

Sıcak kalıp dövmenin avantajları:

Our electric furnace ensures precise temperature control during forging. Combined with advanced equipment and precision dies, this guarantees accurate metal deformation. Consequently, it enhances part density and physical properties significantly.

Hot die forging works with various metals including steel, aluminum, and nickel alloys. The process utilizes metal flow within molds for optimal shaping. Moreover, different molds create diverse components like flanges, gears, and shafts.

Forging primarily improves mechanical properties of metal products. Through heat treatment, it achieves precise dimensions and enhanced hardness. Additionally, it boosts wear resistance for long-lasting performance.

Unlike castings, forging eliminates rolling defects like porosity completely. Therefore, forged parts offer unmatched strength and safety. This makes them ideal for high-performance applications.

Dişliler & Çarklar neden dövülmeli?

Precision Forging: Enhancing Gear & Ring Performance

Gear and ring forging significantly improves metal grain structure. This process creates dense, uniform internal organization. As a result, components gain enhanced strength and toughness. Additionally, wear resistance increases substantially.

Forged parts offer superior load-bearing capacity. Therefore, they excel in demanding operating conditions. Specifically, they perform exceptionally under high loads. They also withstand high speeds and harsh environments effectively.

Key Applications in Wind Power Systems

These forgings are vital for wind turbine components. They’re particularly ideal for rotary bearings. Moreover, they’re essential for drive mechanisms.

Compared to cast alternatives, forgings eliminate defects completely. Consequently, they ensure reliable, long-lasting performance. Most importantly, they enhance safety in critical application.

Biz ne yapıyoruz

Sıcak Dövme

Discover premium hot forgings at Weforging.Our advanced hot forging process delivers strong, precision components.Widely used in automotive, aerospace and industrial sectors.Get high-performance, durable hot forgings today.

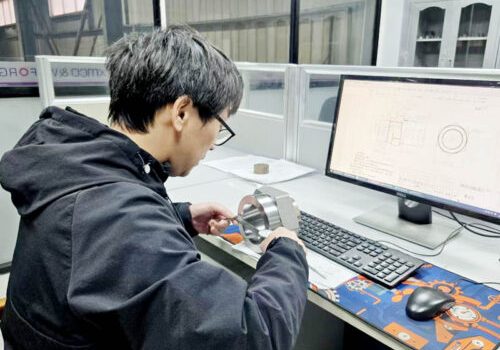

Hassas işleme

Detaylara ve kalite kontrolüne odaklanarak, hassas işleme sürecimiz aracılığıyla üretilen her parçanın en yüksek kalibrede olmasını sağlıyoruz. Prototiplemeden büyük ölçekli üretime kadar, sizi teminat altına aldık.

Soğuk Dövme

Özel soğuk dövme bizim uzmanlık alanımızdır, bu nedenle kişiselleştirilmiş soğuk dövme hizmetleri sunuyor, tam olarak ihtiyaçlarınıza göre metal bileşenler oluşturuyoruz. Tasarımdan üretime kadar kapsamlı yaklaşımımız, projeleriniz için kusursuz soğuk dövme çözümlerini garanti eder.

Montaj ve Tasarım

Custom assembly and design is our core expertise. That’s why we offer personalized services, tailoring assembly and design solutions to your specific requirements. Whether it’s custom electronic devices or specialized mechanical assemblies, we deliver comprehensive technical support, manufacturing, and integration capabilities.

Neden Bizi Seçmelisiniz

Precision forging lab & whole process testing system-the preferred supplier of large equipment enterprises

As a leading gear and ring forging manufacturer, we maintain a comprehensive quality verification system to ensure component reliability in demanding applications:

Material Testing Laboratory

Equipped with advanced spectral analyzers and universal testing machines

Precisely measures tensile strength (up to 1200MPa) and yield strength

Validates material properties for wind turbine gearboxes and heavy construction equipment

Conducts Charpy impact tests for low-temperature performance verification

Precision Measurement Center

Features Japanese Mitutoyo CMM systems with 0.1μm resolution

Ensures dimensional tolerance within IT8 grade specifications

Maintains geometric tolerances including 0.01mm roundness

Verifies assembly accuracy for transmission components

Our gear testing laboratory utilizes precision measuring instruments to comprehensively analyze tooth profile and orientation errors, ensuring compliance with AGMA/ISO accuracy standards.

We implement a rigorous “forging + testing” dual-core quality control system to produce high-reliability forgings for global mining machinery and gearbox applications. This commitment to quality has established long-term partnerships with industry leaders including Columbia Gear (USA) and Sany Heavy Industry.

Özel Dövme ve İşleme Hizmetleri

Sıcak Dövme & Soğuk Dövme

Typical forging process: cutting stock, heating, die forging, removing flash and burr, heat treating as required, finishing, machining teeth and inspection flaw detection, hardness testing, etc.

Haddelenmiş Halka Dövme

Haddelenmiş Halka Dövme: Hidrolik pres ve delme ile yapılan prefabrik metal boşluk, daha sonra CNC makinesi ile haddelenir, yüksek hassasiyetli halka dövmeleri için dövme ve haddelemeyi birleştirir.

Dişliler ve Şaftlar

Our company specializes in manufacturing high – quality gears and shafts. With advanced production techniques and strict quality control, our products offer excellent durability, precise tooth profiles for gears, and accurate dimensions.

Altıgen Somunlar ve Cıvatalar

İster inşaat projeleri, ister makine montajı veya otomotiv onarımları üzerinde çalışıyor olun, altıgen somunlarımız ve cıvatalarımız mükemmel bir çözüm sunar. Sabitleme ihtiyaçlarınızı karşılamak için geniş altıgen somun ve cıvata yelpazemizi keşfedin.

Ürün Uygulaması

Mühendislik ve madencilik makineleri

İleri teknoloji ve hassas üretim ile makinelerimiz uzun ömürlü olacak şekilde üretilmiştir. Geniş ürün yelpazemizi keşfedin ve mühendislik ve madencilik sektörlerindeki operasyonlarınızı geliştirmek için mükemmel çözümleri bulun.

Şanzıman ve tahrik mili

Söz konusu dişli kutusu ve tahrik mili olduğunda özelleştirme en önemli gücümüzdür. Her uygulamanın benzersiz gereksinimleri olduğunu biliyoruz, bu nedenle özel ihtiyaçlarınıza göre uyarlanmış kişiselleştirilmiş çözümler sunuyoruz.

Hidrolik silindir ve valf

Özelleştirme bizim gücümüzdür, Her hidrolik sistemin benzersiz özelliklere sahip olduğunu biliyoruz. Bu nedenle, ihtiyaçlarınıza tam olarak uyan hidrolik silindirler ve valfler tasarlamak ve üretmek için sizinle yakın bir şekilde çalışarak kişiselleştirilmiş çözümler sunuyoruz.

Gemiler ve Otomobiller

We manufacture safe and comfortable mechanical parts for ships and automobiles, including gears and a wide range of high-strength SAE8620 alloy steel forgings/aluminum forgings.

Tarım ve ormancılık ekipmanları

Her bir ekipman parçası, hassas mühendislik ürünü motor parçaları, dayanıklı şanzıman bileşenleri ve sağlam hidrolik sistem parçaları gibi yüksek kalitede üretilmiş bileşenlere sahiptir.

Gevşeme önleyici bağlantı elemanı

Gevşemeyi önleyici bağlantı elemanları, köprü inşaatı, ağır iş ekipmanları ve enerji üretim tesisleri gibi güvenlik ve güvenilirliğin pazarlık konusu olmadığı uygulamalar için idealdir. Montajlarınızı güvenli ve çalışır durumda tutmak için gevşemeyi önleyici bağlantı elemanlarımıza güvenin.

Müşteri Geri Bildirimi

Weforging’s SAE 4140 hydraulic connector forgings demonstrate outstanding quality with core hardness precisely maintained at HRC 34±1.5 (±1 variation in our 20-batch tests). All M32x2-6H threads achieve 100% pass rate in full inspections, while mating surfaces consistently meet the Ra≤0.8μm requirement per AS 4458 standards. Most notably, these connectors have operated flawlessly for 24 months in Pilbara’s harsh mining conditions with zero thread failures, proving significantly more reliable than competing products. Their combination of dimensional accuracy, surface finish quality, and field performance makes them an ideal choice for demanding hydraulic applications.

As a heavy machinery manufacturer, we have maintained a successful five-year partnership with Weforging for gear forging solutions. Their ISO 9001 certified production system guarantees compliance with ASTM E112 grain size standards while achieving an exceptional 99.8% ultrasonic inspection pass rate. Particularly impressive is their computer-controlled heat treatment process, which maintains HB hardness variations within a tight ±15 range. What truly distinguishes Weforging is their professional team that consistently provides prompt technical support and comprehensive PPAP documentation, demonstrating their commitment to quality and customer service throughout our long-term collaboration.

As a precision warp knitting machine manufacturer, we have been thoroughly impressed by the quality of Weforging’s rotor shafts. The entire manufacturing process – from forging blanks to finished products – is completed on Mazak intelligent production lines, achieving three-coordinate measurement accuracy that exceeds our sample specifications by 20%. Each batch is accompanied by comprehensive three-coordinate inspection reports and full material traceability certificates. This consistent excellence in quality has led us to place additional orders for three consecutive years, ultimately replacing our previous European suppliers entirely.

Müşterilerimiz

© 2025 Movely. All Rights Reserved.