Precision CNC Turn-Mill Components | Complex Part Machining Experts

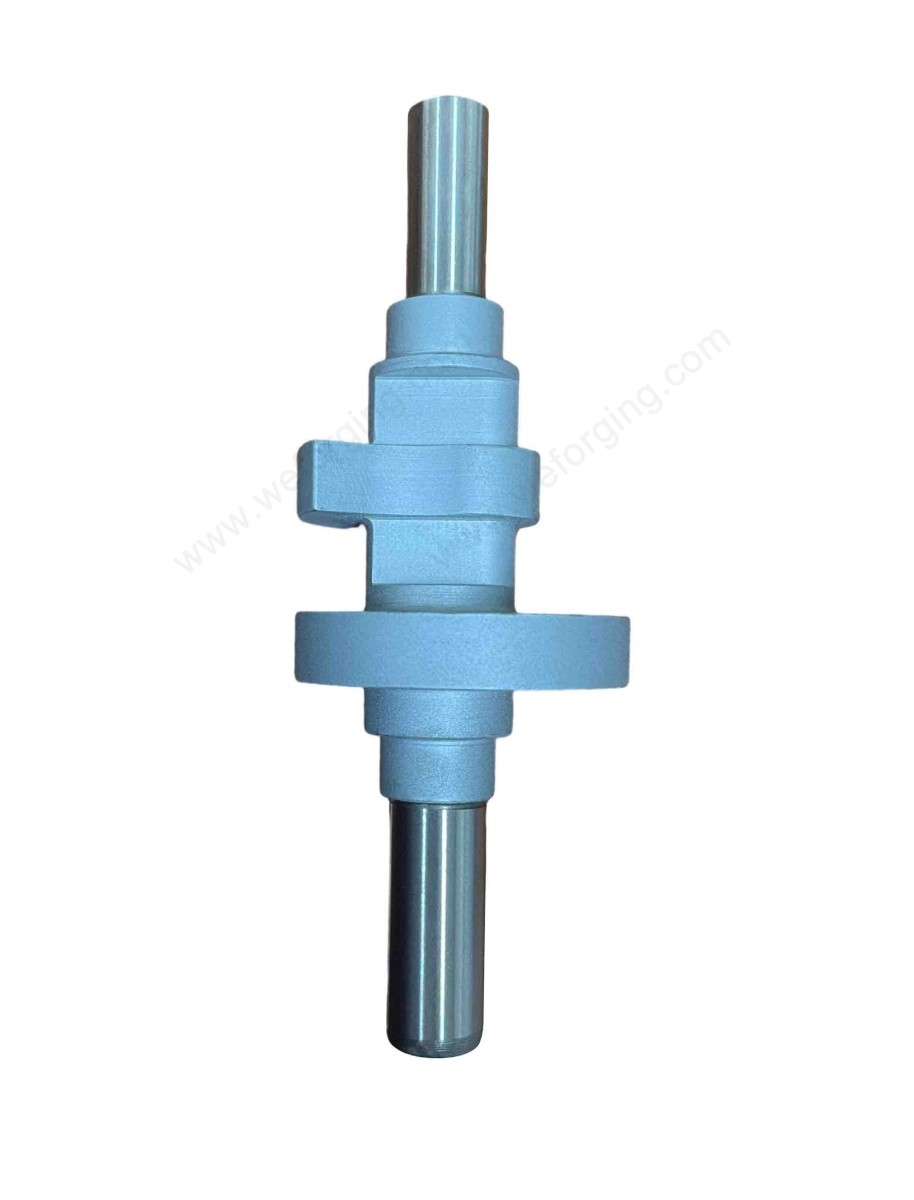

Multi-Axis Turn-Mill Solutions for Critical Applications

Core Capabilities

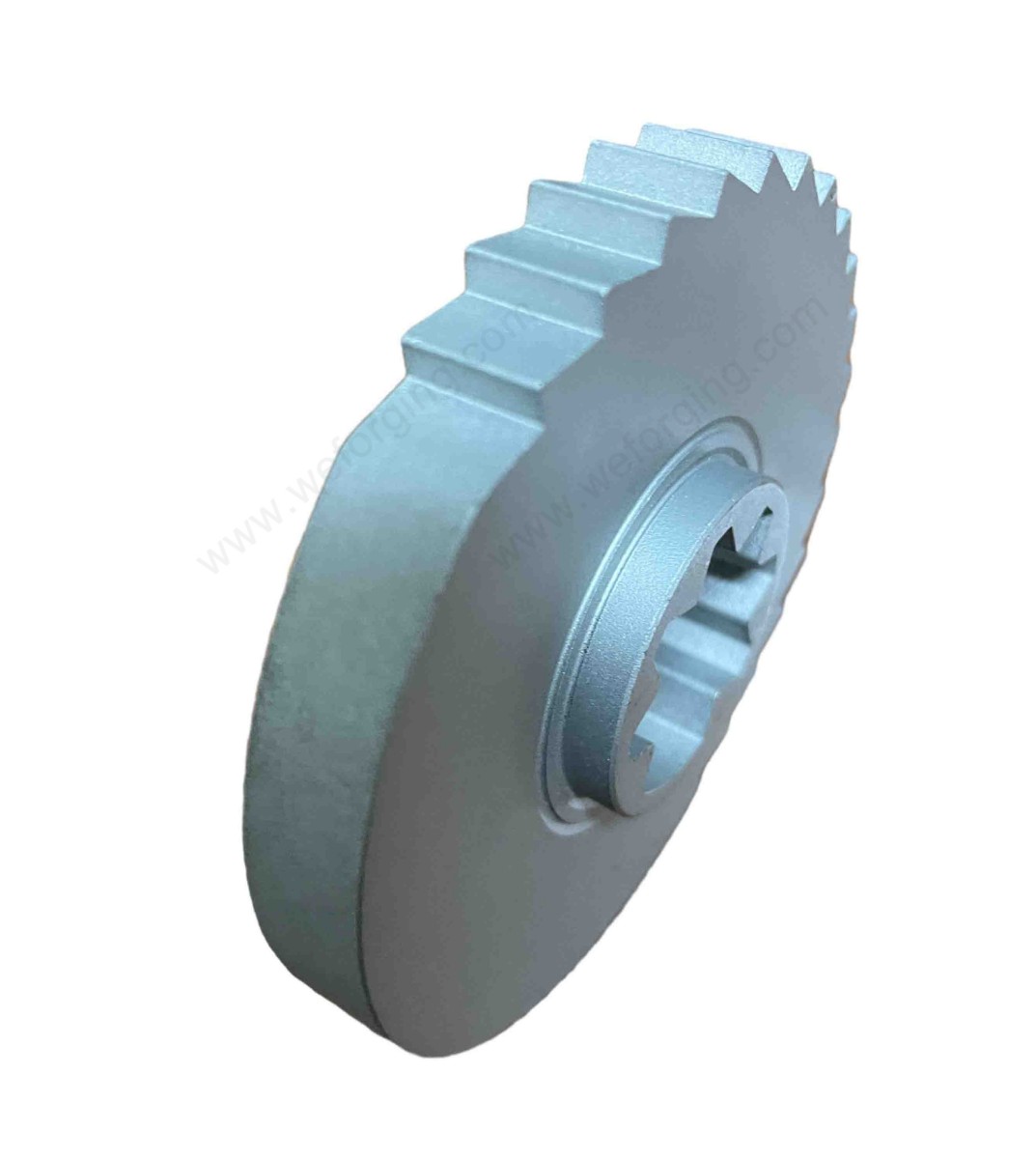

Advanced Machining Technology

5-axis simultaneous machining for complex geometries

Turn-mill integration enables complete part processing in a single setup

Achieves ±0.005″ (±0.127 mm) positional accuracy for critical components

Material Versatility

Aluminum: 6061, 7075

Alloy Steel: 4140, 4340

Stainless Steel: 303, 316L

Titanium: Grade 2, Grade 5

Ideal for aerospace, automotive, medical, and industrial applications

Precision Tolerances

Standard: ±0.005″ (±0.127 mm)

High-Precision: ±0.002″ (±0.05 mm)

Suitable for tight-fit assemblies and tolerance-critical parts

Surface Finishing Options

As-machined finish (Ra 32 μin)

Anodizing (Type II & Type III)

Plating (Nickel, Chrome)

Mirror polishing for high-end aesthetic or medical-grade components

Certifications & Compliance

ISO 9001:2015 Certified

ITAR Registered (U.S. Export Compliance)

NADCAP Accredited (available upon request for aerospace processes)

Industry Applications

Aerospace Components

Landing gear actuators

Flight control linkages

Engine mount fittings

Medical Devices

Surgical instrument shafts

Orthopedic implant parts

Dental handpiece components

Automotive Systems

Transmission synchronizers

Fuel injection nozzles

Steering column shafts

Industrial Equipment

Hydraulic valve bodies

Pneumatic fittings

Pump shaft assemblies

Why Choose Our Turn-Mill Services?

20+ Years Complex Part Expertise

State-of-the-Art Equipment:

Mori Seiki NTX Series

Mazak Integrex e-Series

Rigorous Quality Control:

Full CMM Inspection (Zeiss, Mitutoyo)

Material Traceability Certification

Fast Production Cycles:

15-Day Standard Lead Time

7-Day Rush Service Available

Engineering Support:

Free DFM Analysis

Prototyping Services

Technical Specifications

| Parameter | Capability |

|---|---|

| Max Turning Diameter | 12″ (300mm) |

| Max Turning Length | 24″ (600mm) |

| Mill Tool Capacity | 40+ Tools |

| Spindle Speed | 10,000 RPM |

Project Workflow

Design Consultation – Free DFM review

Process Planning – Custom machining strategy

Production – CNC turn-mill operations

Finishing – Surface treatment options

Inspection – Full dimensional report

Delivery – Worldwide shipping

📞 Contact us for your complex part requirements!