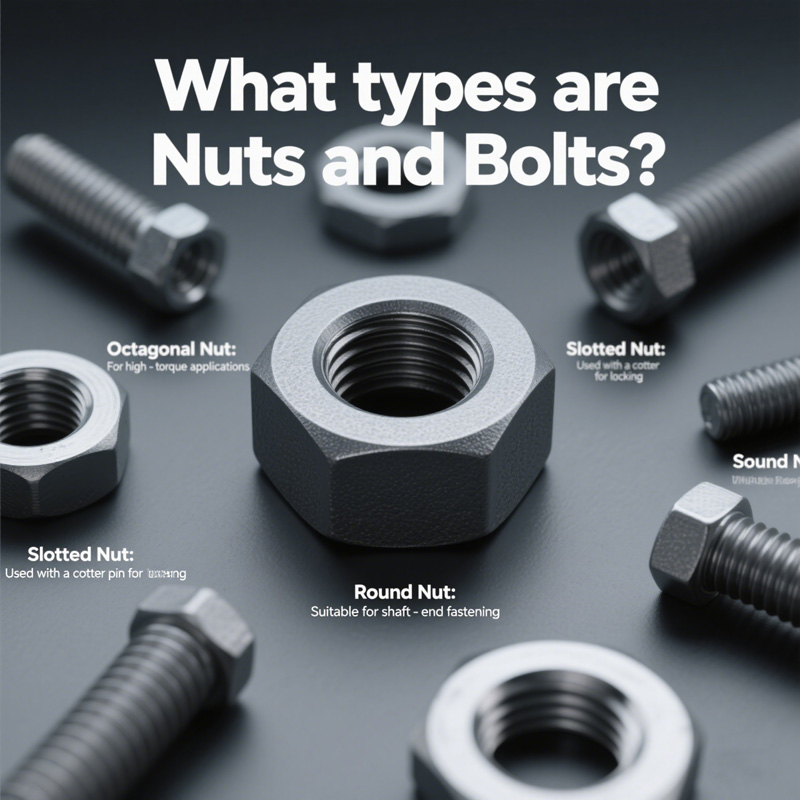

Optimized and SEO-Enhanced Version: How to Choose the Right Fasteners for Your Industrial Needs

Choosing the right fasteners is critical for ensuring the durability, safety, and performance of mechanical assemblies across industries. At Weforging Manufacturing, we specialize in delivering custom fasteners, including nuts and bolts, that meet stringent international standards through advanced forging and CNC machining technologies.

Understanding Fastener Standards and Strength Grades

Different applications require compliance with specific fastener standards and strength classifications. Below is a detailed comparison of common international standards:

| Standard | Common Grades | Typical Use Cases |

|---|---|---|

| ISO 898-1 | 8.8, 10.9, 12.9 | Machinery, construction, vehicles |

| ASTM A325/A490 | Type 1, Type 3 | Structural steel connections |

| SAE J429 | Grade 5, Grade 8 | Automotive, agriculture |

Selecting the Right Fastener Material

Fasteners are manufactured from various materials, each offering unique advantages:

Carbon Steel: Economical and suitable for general applications.

Alloy Steel: High strength, ideal for hot forging critical parts.

Stainless Steel: Corrosion-resistant, perfect for marine and chemical environments.

Brass/Copper Alloys: Conductive and decorative uses.

Heat Treatment for Enhanced Performance

Heat treatment processes improve fastener properties:

Quenching and Tempering: Increases hardness and tensile strength.

Carburizing: Enhances surface wear resistance.

Annealing: Relieves internal stress for better durability.

Surface Treatments for Corrosion Resistance

Protect fasteners from corrosion with these finishes:

| Surface Finish | Salt Spray Resistance | Pros | Cons |

|---|---|---|---|

| Zinc Plating | 72–96 hours | Low cost, decent protection | Prone to white rust |

| Hot Dip Galvanizing | 500–1000 hours | Strong corrosion resistance | Thick coating affects thread fit |

| Dacromet Coating | 1000+ hours | Excellent, uniform protection | Higher cost |

| Phosphate Coating | 48–96 hours | Good oil absorption, anti-galling | Limited outdoor use |

Advanced Manufacturing Processes at Weforging

We leverage cutting-edge techniques to produce precision-engineered fasteners:

- Hot & Cold Forging: High-strength parts with superior grain flow.

- CNC Machining: Precise threading and head shaping.

- Ring Forging: Ideal for large-diameter washers or collars.

- Gear and Shaft Integration: Specialized mechanical assembly solutions.

Customization Support:

- Non-destructive testing (NDT)

- Mechanical property analysis

- Salt spray testing

- Material traceability and certification

Why Choose Weforging Manufacturing?

With 42+ years of experience, we offer:

✅ End-to-end production from design to delivery.

✅ Industry expertise in mining, transport, energy, and construction.

✅ ISO 9001-certified facilities and global shipping.

✅ OEM and custom branding support.

Conclusion

Selecting the right fasteners involves balancing standards, materials, treatments, and quality. At Weforging Manufacturing, we provide tailored solutions to meet your operational needs.

🔗 Explore our fastener solutions or contact our engineering team for custom requirements today!

Email:wf-kevin@outlook.ocm