What is Rolled Ring Forging?

Rolled ring forging, also known simply as “ring forging,” is a precise metal forming process used to manufacture strong, seamless rings.A forged ring is manufactured by first punching a hole in a solid, round metal billet and then shaping it into a seamless ring through a high-temperature rolling and forging process. Compared to rings produced by casting or welding, rolled ring forgings offer significantly enhanced strength, toughness, and fatigue resistance, making them ideal for high-stress environments.

In today’s advanced industries, rolled ring forging is valued for its cost-efficiency, material optimization, and superior mechanical performance. At Weforging Manufacturing, we specialize in custom ring forging solutions tailored to your specific needs. Our products include gear rings, flange forgings, and slewing bearing rings, all designed to meet the demands of heavy-duty and precision-critical applications.

Rolled Ring Forging Process Steps

At weforging manufacturing, the rolled ring forging process follows a standardized, high-precision workflow to ensure the final product meets strict industry standards.

1. Raw Material Cutting (Billet Shearing)

This process involves choosing the appropriate metal material and size specification, usually mainly in the form of bars. Material: Carbon steel, alloy steel SAE8620H, etc., stainless steel or non-ferrous metals, etc. The billets are then cut to the required length using billet shearing, ensuring accurate weight and volume for forging.

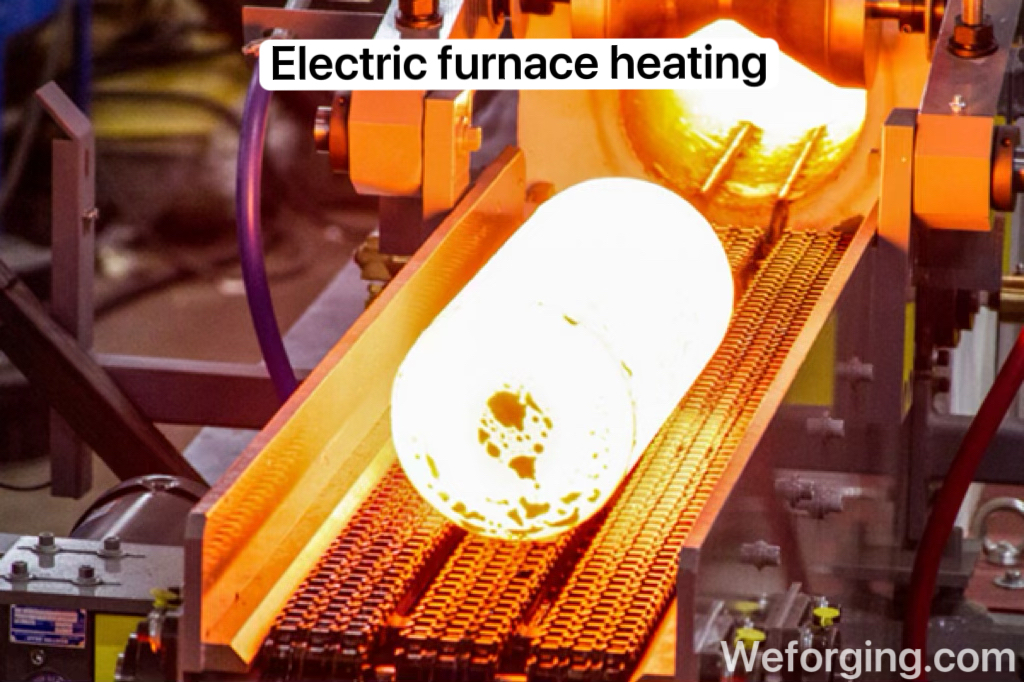

2. Electric Furnace Heating

After cutting, the billets are heated in an electric furnace to a forging temperature, usually between 1,100°C to 1,250°C (2,000°F to 2,300°F). Controlled heat treatment forging ensures uniform temperature distribution, which is essential for achieving superior grain flow and material strength.

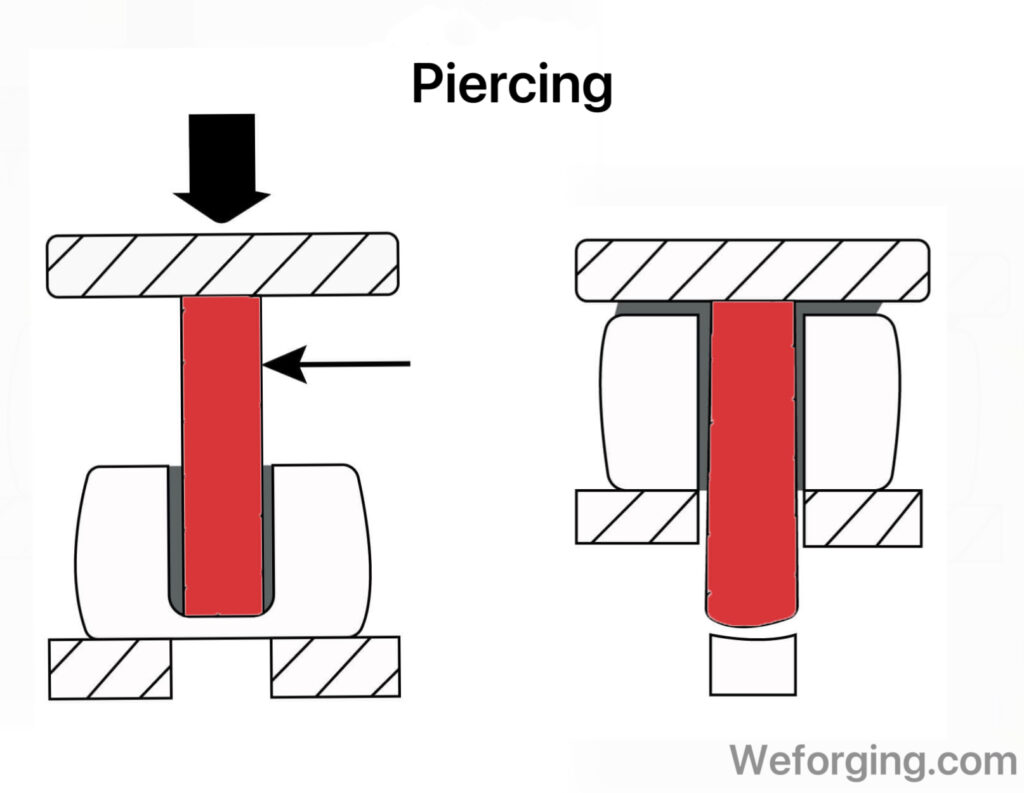

4. Punching (Piercing)

Drill a hole in the center of the billet to form a donut-shaped blank. The function of this hole is to provide a mandrel for support during rolling.

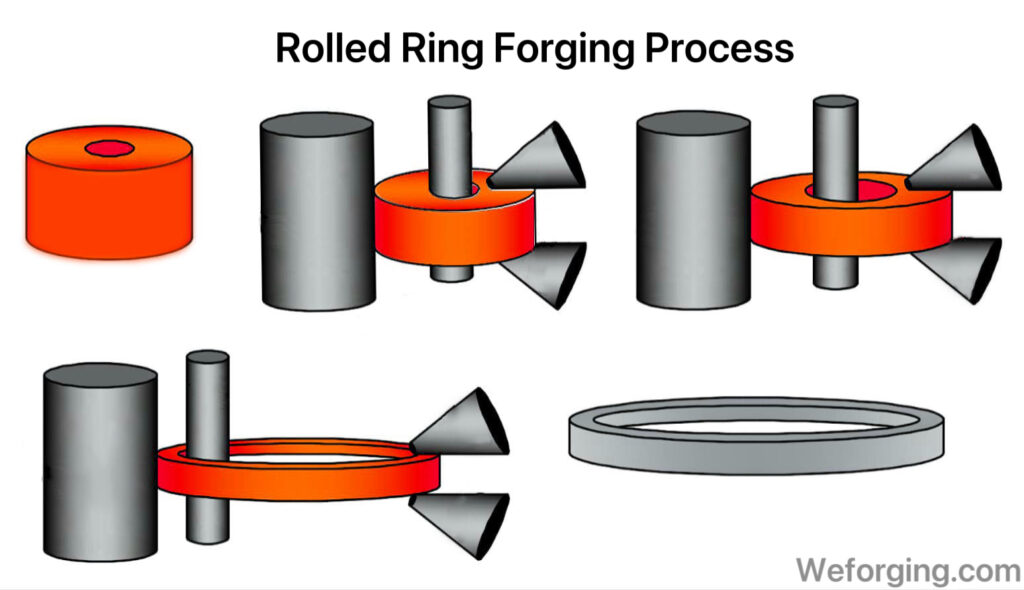

5. Ring Rolling (Ring Mill Forging)

The donut-shaped blank is then placed onto a ring rolling mill. Here, the blank is rotated and squeezed under immense radial and axial forces to expand the inner and outer diameters to the desired size. Ring rolling is highly efficient and minimizes material waste compared to alternative methods.

Throughout the process, our CNC machining technology ensures precision dimensions and tight tolerances, enabling us to deliver high-quality custom forging solutions.

Benefits of Rolled Ring Forging

Rolled ring forging offers significant advantages over cast or welded rings:

1. Superior Strength and Toughness

Thanks to the continuous grain flow achieved during forging, forged rings provide higher strength, better impact resistance, and fatigue performance.

2. Material Efficiency

The process uses material more efficiently, generating less waste compared to cutting or casting a solid ring.And it is much more efficient.

3. Cost-Effectiveness

Rolled ring forging can produce large diameter rings economically, making it ideal for applications where strength-to-weight ratio matters,And roughly fabricate a certain physical structure for the subsequent process.

4. Dimensional Flexibility

The rolled ring forging process supports a wide range of diameters, thicknesses, and heights, all customized to your specific design requirements.

5. Enhanced Metallurgical Properties

The forging process refines the metal structure, improving internal soundness and ensuring reliability in critical applications such as gear rings and slewing bearings.

At weforging manufacturing, our custom metal forging and CNC machining capabilities ensure that every forged ring meets or exceeds your expectations.

Applications of Rolled Ring Forgings

Rolled ring forgings are widely used across multiple industries due to their high performance and adaptability. Key application areas include:

1. Gear Rings

Gear rings forged through the rolled ring process are commonly used in large gear assemblies for heavy machinery, wind turbines, mining equipment, and marine transmissions. The superior strength of forged gear rings ensures reliable torque transmission and long service life.

2. Flange Forgings

Rolled ring flanges are essential components in pipelines, pressure vessels, and mechanical assemblies where leak-proof connections are required. Our custom flange forging solutions meet international standards such as ASME, ANSI, and DIN.

3. Slewing Bearings

Slewing bearings, used in cranes, excavators, wind turbines, and rotating machinery, often incorporate forged rings as raceways. The high load-bearing capacity and dimensional precision of our forged rings make them ideal for slewing bearing assemblies.

4. Aerospace and Energy

Forged rings are critical in aerospace engines, gas turbines, and nuclear power plants, where high strength-to-weight ratios and reliability are non-negotiable.

5. Oil & Gas and Heavy Equipment

In oil & gas drilling equipment and heavy industrial machinery, rolled rings are used in pressure-containing parts and rotating assemblies requiring robust performance under harsh conditions.

Why Choose weforging Manufacturing?

As a trusted custom forging manufacturer, weforging manufacturing provides end-to-end rolled ring forging services, from billet cutting and forging to CNC machining, heat treatment, and final inspection.

🔩 Our Core Capabilities Include:

Custom forged rings in a wide range of materials: carbon steel, alloy steel, stainless steel, etc.

Precision CNC machining in-house to meet tight tolerance requirements.

Specialization in gear rings, flanges, and slewing bearings.

Heat treatment processes to enhance strength and durability.

Full material traceability and strict quality control at every stage.

Partnering with weforging means you benefit from shorter lead times, cost-effective production, and expert technical support. Whether you need a single custom forged ring or a large batch production, we deliver solutions tailored to your needs.

Contact us today to discuss your next rolled ring forging project and discover how weforging manufacturing can support your business with high-quality, precision-engineered forged rings.

»Email:wf-kevin@outlook.com

»Web:www.weforging.com

»Contact Us:https://www.weforging.com/contact-forging-company/