Precision. Performance. Partnership.

At Weforging, every solution starts with understanding your requirements.

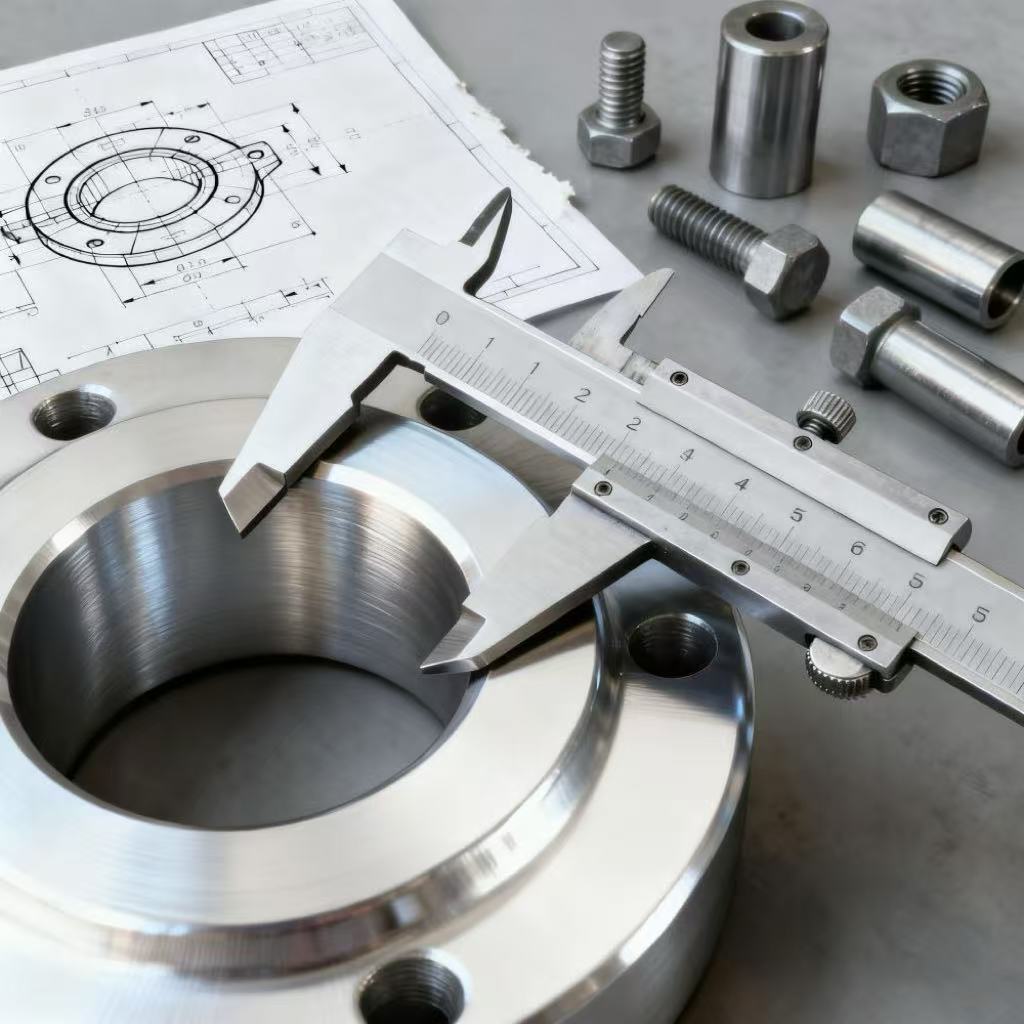

We support procurement managers and engineers through dedicated service, technical precision, and responsive production.

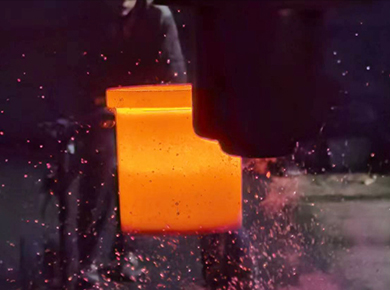

Our forging and CNC machining expertise ensures quality, consistency, and full traceability.

Weforging offers every customer:

- Comprehensive Engineering Support

- Cost and Efficiency Analysis

- Near-Net Forging Capability

- Value-Added Services

- Program and Batch Management

- Fast Delivery & Global Logistics

- Certified Quality System

- Diverse Materials & Custom Sizes