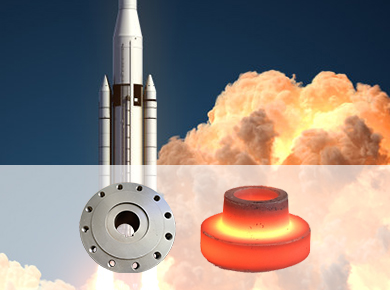

Weforging Builds Rocket Couplings for MTU

In the aerospace industry, reliability and precision are essential. At Weforging, we deliver advanced aerospace forging solutions that combine traditional forging expertise with modern CNC machining. Our forged components, including aerospace gears, shafts, and rings, are engineered from high-strength alloys and stainless steels to ensure durability and outstanding performance in the most demanding environments.

Aerospace Forging Capabilities

We apply hot-die forging and rolled ring forging to achieve superior grain flow and material density. These methods enhance fatigue resistance, toughness, and stability while reducing material waste. Supported by multi-axis Mazak CNC machining centers and precision grinding, our forged parts meet strict dimensional tolerances and international standards.

Aerospace Forged Components

Weforging manufactures a wide range of forged aerospace parts, such as:

Aerospace gears and shafts – high precision, ideal for engines and gearboxes.

Turbine discs and blades – forged for high-temperature and high-stress conditions.

Landing gear components – strong, reliable parts ensuring safety in flight.

Structural rings – lightweight aerospace forgings with superior strength.

Satellite and rocket hardware – custom-engineered for extreme space applications.

Design and Engineering Support

At Weforging, our engineering team provides full Design for Assembly (DFA) and Design for Manufacturability (DFM) services. We combine 2D/3D modeling, stress simulation, and process optimization to ensure every aerospace component meets performance, weight, and safety requirements. Furthermore, our team collaborates closely with OEM engineers to refine designs, improve material utilization, and reduce production risks. This proactive approach shortens development cycles, lowers costs, and ensures seamless integration of forged parts into aerospace systems.

Quality and Certification

We understand that aerospace forging requires uncompromising quality and reliability. All forged components undergo ultrasonic testing, magnetic particle inspection, and CMM verification to confirm dimensional accuracy and structural integrity. In addition, we implement heat treatment and hardness testing to meet performance demands under extreme conditions. Operating under ISO 9001 and PPAP standards, Weforging guarantees complete traceability, consistent quality, and compliance with global aerospace requirements—helping our partners meet strict regulatory and safety standards.

Global Applications

Our precision-engineered aerospace forgings are trusted worldwide for mission-critical performance. They play a key role in commercial aircraft, military aviation, gas turbines, satellites, and space launch vehicles. These forged parts deliver strength, fatigue resistance, and long service life under high stress and temperature. Moreover, Weforging supports global OEMs in Europe and North America with reliable supply chains and multilingual technical service. As a result, we continue to strengthen partnerships and provide aerospace components that improve efficiency, reliability, and safety in the world’s most advanced industries.