Engineering Excellence in Motion

When turbine efficiency hinges on micron-level precision, our forged rotor shafts become the heartbeat of your machinery. Unlike cast or billet alternatives, each shaft begins as a vacuum-degassed SAE 4340 ingot – hammer-forged at 2,200°F to align grain flow with stress vectors. Picture molten steel dancing under 10,000-ton presses, crystallizing into dense blanks with 30% higher fatigue strength than industry standards.

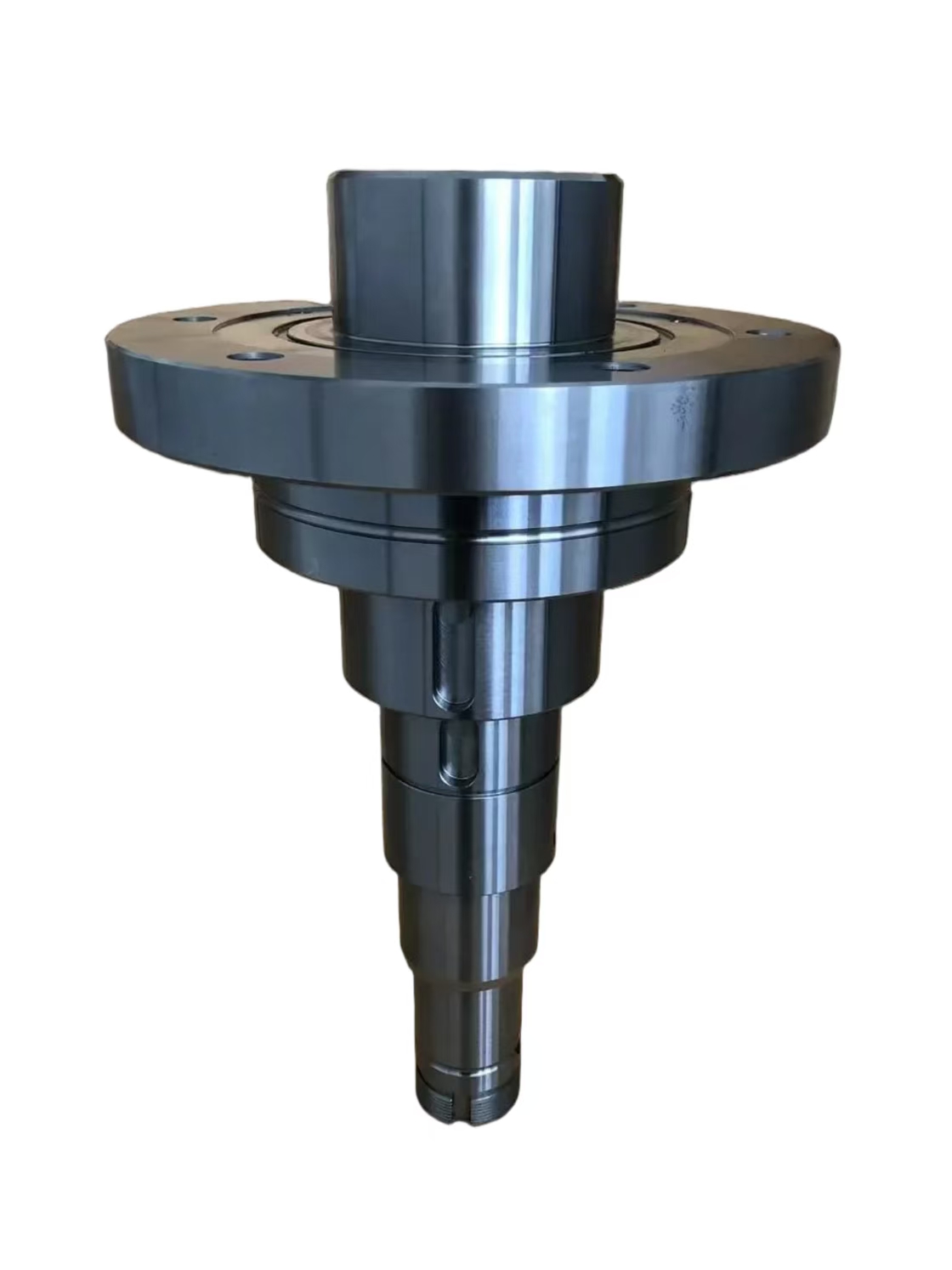

The Anatomy of Precision

Stage 1: Forging Integrity

Material: Vacuum arc remelted (VAR) 4340 steel

Process: Radial forging > Controlled cooling > UT inspection per ASTM E588

Outcome: Zero porosity with 1:3 aspect ratio fiber grain

Stage 2: CNC Alchemy

Our 5-axis Hermle C62 machines transform forged blanks into aerodynamic masterpieces:

Why Forged > Machined-from-Billet?

| Parameter | Forged Shaft | Billet Shaft | Advantage |

|---|---|---|---|

| Fatigue Life | 2.1×10^9 cycles | 9.3×10^8 cycles | 125% longer |

| Residual Stress | 12 MPa (compressive) | 85 MPa (tensile) | Reduced cracking |

| Cost at 500+ units | $1,820/pc | $2,150/pc | 18% savings |

Real-World Endurance

Consider the Helios-7 geothermal turbine at Larderello Field:

Challenge: Shaft failures every 14 months from H2S corrosion

Our Solution:

Core: 4340 steel forged with 3% Cr diffusion layer

Surface: Laser-clad Stellite 6B (HRC 60)

Result: 63 months operation with <5μm pitting (still running)