Weforging Supports China Sky Eye Project

Introduction: Behind the China Sky Eye - FAST Telescope

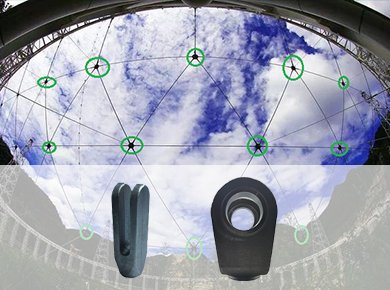

Nestled deep in the mountains of Pingtang, Guizhou province, the Five-Hundred-Meter Aperture Spherical Radio Telescope (FAST), known as “China’s Eye of Heaven“, stands as the largest and most sensitive radio telescope in the world. It gazes into the vastness of space, uncovering the universe’s mysteries. An essential contributor to this monumental project is Weforging Manufacturing Company.

The construction of FAST is an unprecedented super project, with strict demands on every component. The quality of the forged joints directly affects the stability and observation accuracy of the entire telescope. Weforging was chosen for its deep technical expertise and excellence in forging and machining, providing key joint forgings for the telescope’s assembly.

The Forging Process: Overcoming Challenges

Selection for Extreme Conditions

To support the advanced requirements of FAST, the forgings needed to combine exceptional strength with superior corrosion resistance. Weforging invested heavily in research and development, continuously refining the forging process to achieve optimal results. Through a series of carefully controlled trials, our team perfected a specialized fork lug connection method. This ensured that the internal microstructure of the metal remained tough yet strong, enabling the forgings to perform reliably under long-term loads and challenging environments while maintaining stability and durability.

Precision Machining for Reliable Construction

The structural design of FAST demands high-precision dimensions to guarantee the telescope’s overall stability, including its ability to withstand additional weight such as snow accumulation. To meet these requirements, Weforging applied world-class machining technology supported by an experienced technical team. Each stage—from roughing to finishing—was executed in strict accordance with design standards, with comprehensive inspections at every step. This meticulous approach ensured that every forging achieved a perfect fit with surrounding components, allowing for faster assembly, enhanced reliability, and long-lasting performance.

Key Achievements: Forging the Backbone of FAST

Today, the joint forgings manufactured by Weforging are quietly playing a vital role in the efficient operation of the Eye of Heaven. These forgings act as the strong bonds that securely connect all the components of FAST, ensuring the system’s stability and accuracy during its observations. Since its launch, FAST has achieved significant milestones in pulsar detection and neutral hydrogen observation, with Weforging contributing to these remarkable accomplishments.

Why Procurement Teams Choose Weforging

Risk-Free Supply – Stable production capacity and reliable material sourcing

One-Stop Manufacturing – Forging + machining + assembly under one roof

Project-Ready Quality – Certified inspections and testing for critical applications

On-Time Delivery – Streamlined workflow to meet tight project schedules

Cost Efficiency – Material utilization and precision processes reduce waste and rework

Tailored for Heavy-Duty Applications

Our forging expertise supports procurement needs for gear blanks, hydraulic cylinder components, offshore system parts, and custom fasteners. Each product is engineered to withstand extreme loads, harsh environments, and long operating cycles, ensuring durability and reliability for mission-critical equipment.

Partner with Weforging for Your Next Project

Procurement leaders in marine, mining, construction, and energy industries trust Weforging to deliver parts that perform under pressure. Whether you need prototype development or mass production for global projects, we provide a risk-free, dependable, and cost-effective supply solution.

👉 Contact us today to discuss your project requirements and secure a competitive advantage with Weforging.