Precision Forged Components for Bridge Construction

— Weforging provides core fastening solutions for Century Engineering

Introduction

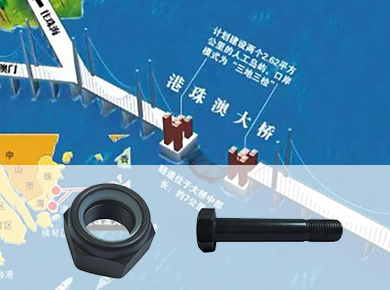

As a leading bridge forging supplier, Weforging was honored to participate in the HZMB Bridge Case, providing critical bridge fasteners designed for exceptional strength and corrosion resistance.The Hong Kong–Zhuhai–Macao Bridge is one of the world’s longest sea-crossing structures, demanding components that can endure heavy loads, saltwater, and vibration.

Weforging’s integrated forging + CNC machining + testing process ensured the reliability and long-term performance of every high-strength hex bolt and precision lock nut used in the project.

Project Scope & Supplied Components

For the HZMB bridge case, Weforging supplied forged bridge fasteners — mainly high-strength hex bolts and marine-grade lock nuts — used in anchoring, expansion joints, and structural connections.

High-Strength Hex Bolts: Hot-forged from 42CrMo alloy steel, these bolts achieved tensile strength above 900 MPa with consistent dimensional control.

Precision Lock Nuts: Machined from forged blanks, finished with anti-corrosion coating to ensure long service life in marine environments.

These forged fasteners were installed across multiple bridge sections, maintaining joint stability under dynamic stress, wind vibration, and continuous traffic loads.

Manufacturing Process

Weforging’s bridge forging process integrates advanced technology to ensure product consistency.

1️⃣ Forging Stage: Controlled hot-forging aligned the metal grain flow with stress direction, increasing strength and fatigue life.

2️⃣ CNC Machining: Mazak centers perform threading, surface finishing, and tolerance control within ±0.01 mm, producing precise bridge fasteners that meet international standards.

3️⃣ Testing & Validation: All batches passed UT, MPI, hardness, torque, and fatigue tests following ISO 9001:2015 procedures.

4️⃣ Surface Protection: Zinc-nickel and phosphating coatings provide over 1000 hours of salt-spray resistance, ideal for marine-grade fasteners used in bridges and offshore structures.

Engineering Advantages for the HZMB Project

Weforging’s technical excellence as a bridge forging supplier was demonstrated through multiple innovations:

Marine-Grade Durability: Enhanced corrosion resistance through special coatings and heat treatment.

Dimensional Accuracy: Every high-strength hex bolt and lock nut verified by CNC measurement.

Traceability: Laser-marked codes for batch tracking.

Integrated Quality Control: Testing performed in ISO-certified labs.

Customization: Bridge fasteners tailored to OEM drawings and unique engineering requirements.

Performance & Reliability

Since completion, all supplied Weforging bolts and nuts have performed flawlessly in service, with zero corrosion and full torque retention. Their durability and accuracy have contributed to the HZMB’s continued stability and safety, reinforcing Weforging’s reputation as a trusted partner in global bridge engineering.

Contact

Looking for a reliable bridge forging supplier for your next infrastructure or marine project?

Contact Weforging to discuss custom bridge fasteners, marine-grade fasteners, or OEM forging solutions.