Precision Forging Parts: Applications and Advantages

In today’s global manufacturing industry, precision forging parts have become indispensable for sectors that require strength, durability, and exact tolerances. From automotive gears to heavy machinery shafts, forged components deliver performance that casting or welding cannot match. At Weforging, we integrate hot forging presses, Mazak CNC machining centers, and in-house testing laboratories to produce reliable solutions for international clients. This article explores the applications and benefits of precision forging, and why Weforging has earned long-term trust from global partners in automotive, mining, and marine equipment industries.

What Are Precision Forging Parts?

Precision forging parts are manufactured through advanced forging methods that ensure exceptional strength, dimensional accuracy, and superior material integrity. Unlike conventional forging or casting, precision forging achieves tolerances as low as ±0.1 mm, minimizing the need for secondary machining.

These parts are critical in industries where safety and reliability are non-negotiable. For example, automotive gears and heavy machinery shafts must handle repetitive stress and torque without failure. Forging aligns the metal’s grain structure with the geometry of the part, improving fatigue resistance and overall tensile strength.

At Weforging, our production integrates hot forging, cold extrusion, and CNC machining. We supply gear rings and gears and shafts that meet AGMA and ISO standards. This allows us to serve sectors such as automotive, mining, and marine equipment with consistent quality.

Applications in Automotive and Heavy Machinery

The applications of precision forging parts extend across industries that require both high strength and reliable performance under extreme conditions. One of the largest sectors benefiting from precision forging is the automotive industry. Components such as automotive gear shafts, connecting rods, crankshafts, and transmission parts demand exceptional durability and dimensional consistency. Forging ensures that these parts can handle repeated stress and torque without failure.

At Weforging, we supply gears and shafts specifically engineered for heavy-duty vehicles and passenger cars. By combining hot forging and CNC machining, our production team guarantees accurate tooth profiles and smooth finishes that comply with AGMA and ISO standards. These qualities are essential for ensuring quiet, efficient, and long-lasting vehicle operation.

Beyond automotive, the heavy machinery and mining industries also rely heavily on precision forging parts. For example, mining equipment components such as drill bits, couplings, and bearing housings must withstand harsh working environments and high impact forces. Forging not only improves their strength but also reduces the risk of microcracks that could shorten service life.

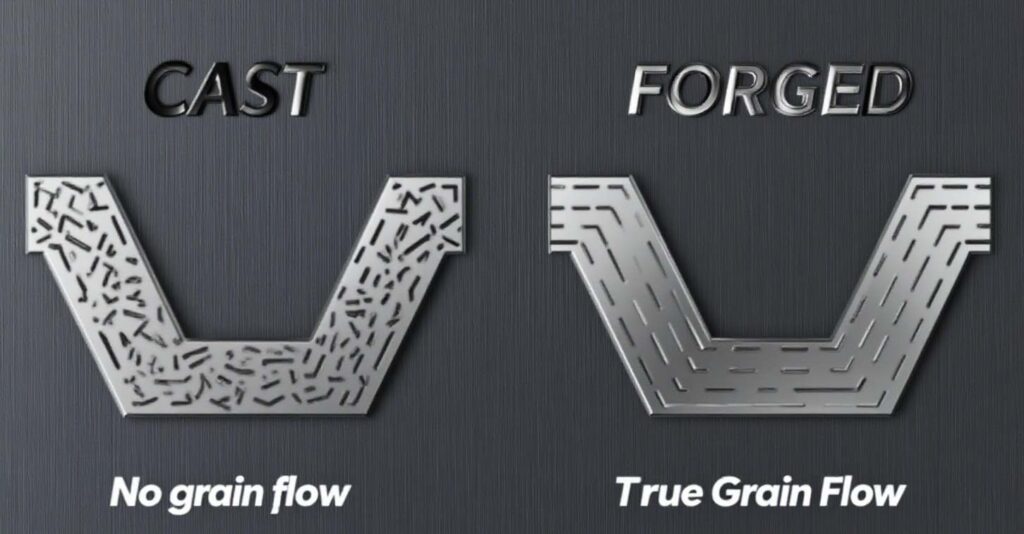

Comparing Forging vs Casting Strength

When comparing forging vs casting strength, the advantages of forging are clear. Forged components have superior grain structure, tensile strength, and fatigue resistance compared to cast parts, which are more prone to porosity and microcracks.

For example, tensile strength of forged parts can be up to 30% higher than cast equivalents, making them more reliable for high-load applications. This is why industries prefer forging for safety-critical components such as automotive gear shafts and mining equipment components.

Authoritative organizations like AGMA and ASTM also highlight forging as the recommended choice for applications requiring long-term durability.

Why Choose Weforging as Your Supplier

Selecting the right supplier for precision forging parts is crucial. At Weforging, we emphasize a “forging + CNC + testing” dual-control system, ensuring each component meets AGMA/ISO standards. Our clients include global leaders such as Columbia Gear (USA) and Sany Heavy Industry.

We offer a complete range of fasteners, gear rings, and gears and shafts, supported by advanced Mazak CNC centers and coordinate measuring machines (CMMs). This allows us to deliver quality that stands out in competitive industries.

Conclusion

Precision forging parts are the foundation of reliable performance in automotive, mining, and marine industries. By choosing forging over casting, manufacturers gain superior strength, fatigue resistance, and cost efficiency.

At Weforging, we combine forging expertise, CNC machining, and rigorous quality testing to deliver custom forged components that meet international standards. Our ability to handle mining equipment components, automotive gear shafts, and gears and shafts sets us apart as a trusted supplier for global clients.

Custom Solutions for Industrial Clients

Every industry has unique requirements, and Weforging specializes in delivering custom forged components tailored to client needs. Whether it is mining equipment components or marine transmission parts, our engineering team works closely with customers to transform drawings into finished products.

- Upload 2D/3D Drawings (PDF, DWG, DXF, STEP, IGES).

- Specify Material & Quantity & Technical Requirements.

- Receive free DFM feedback within 24h.