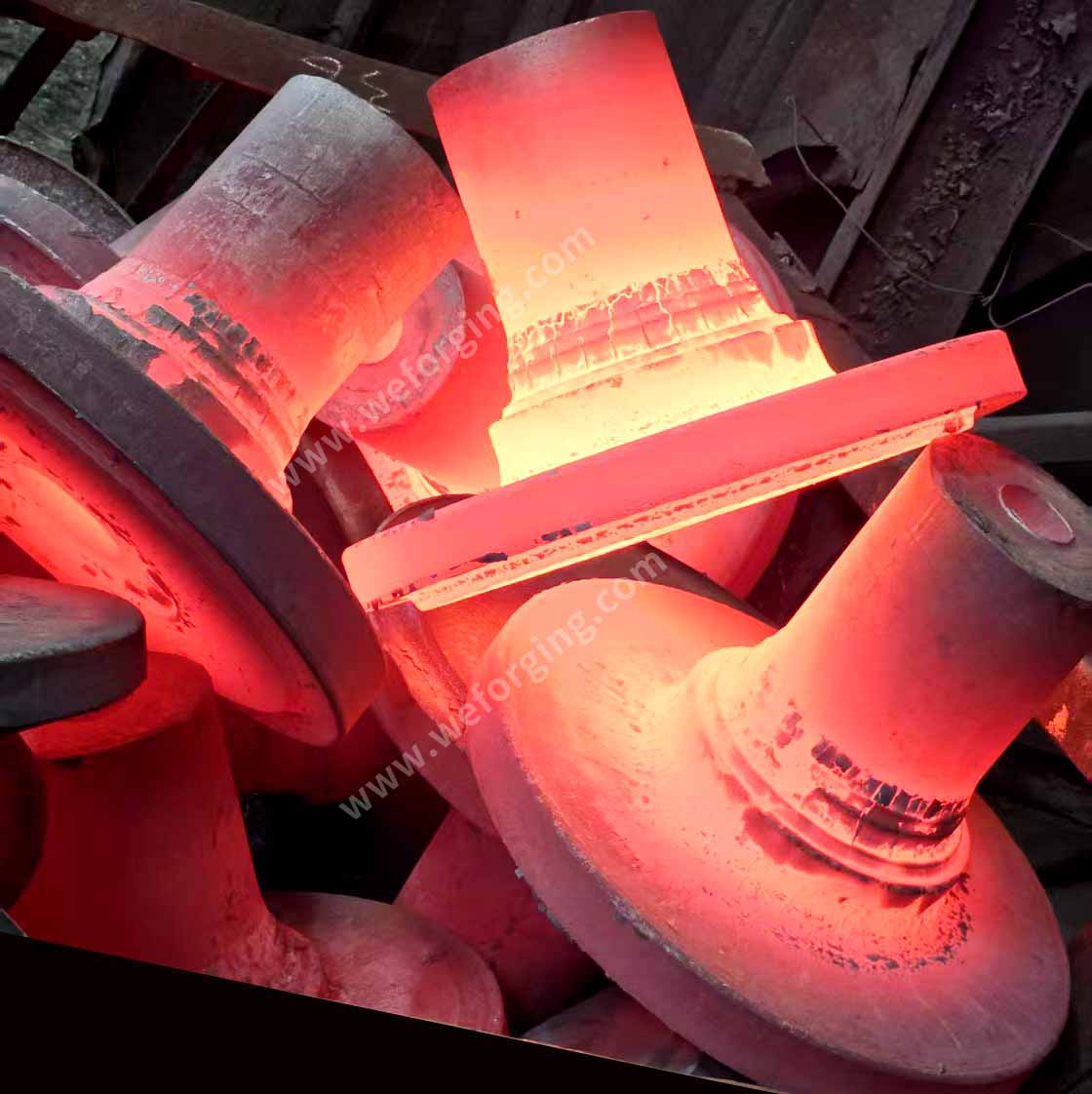

Forged Flange Forgings — Strong, Reliable Pipe Connections

At Weforging, we manufacture high-strength flange forgings designed for performance, precision, and durability. Produced from carbon steel, alloy steel, and stainless steel, our flanges are available in weld neck, slip-on, blind, socket weld, and threaded designs. Each product is hot forged or cold forged, then CNC machined to achieve tight tolerances and smooth sealing surfaces. Trusted by OEMs across oil & gas pipelines, petrochemical plants, wind power, marine engineering, and heavy machinery, Weforging ensures every flange meets ISO 9001 standards with full testing and documentation. Our goal is to deliver reliable, custom flange solutions that optimize efficiency and reduce costs for global industries.

Materials & Flange Types

Weforging offers forged flanges in a wide range of materials, including A105 carbon steel, 20Mn, 42CrMo4 alloy steel, and stainless steel grades 304/316. These materials provide excellent strength, toughness, and corrosion resistance, making them suitable for pipelines, pressure vessels, and heavy machinery.

Our production covers all major flange types such as weld neck, blind, slip-on, threaded, and socket weld designs. Each flange can be hot forged, CNC machined, and heat treated to meet strict dimensional tolerances. We also provide custom flange forgings based on client drawings and industry standards, ensuring reliable performance in demanding oil & gas, petrochemical, marine, and energy applications.

Why Choose Our Flange Forgings?

Our flange forgings are applied in:

Oil & Gas pipelines – high-pressure joints ensuring safe and efficient transport.

Petrochemical equipment – resistant to extreme heat and corrosion.

Wind turbines and power generation – large forged rings and flanges for turbines and towers.

Marine engineering – offshore platforms, vessel piping, and propulsion systems.

Heavy machinery – housings, gearboxes, and structural connections for long-term durability.

Quality Assurance

Every flange is tested with CMM inspection, ultrasonic (UT), and magnetic particle testing (MPI). Additional services include heat treatment, metallurgical analysis, and hardness verification. Weforging complies with ISO 9001 and offers PPAP documentation when required, ensuring traceability and confidence for global OEMs.

Why Partner with Weforging

Weforging offers full in-house capability, covering every stage from forging to CNC finishing, quality inspection, and packaging. In addition, we provide custom designs based on client drawings to meet unique project requirements. Our production system is highly flexible, allowing us to handle both small batches and large-volume orders efficiently. As a result, we can guarantee fast delivery to Europe and North America without compromising on quality. With competitive pricing and consistent reliability, Weforging has become a trusted partner for OEMs worldwide, supporting industries that demand strength, precision, and long-term performance.

Contact Us

Looking for a reliable flange forging supplier? Weforging provides fast lead times, global logistics, and engineering support to help customers optimize design and reduce costs. Contact us today or request a quote to discuss your flange project.