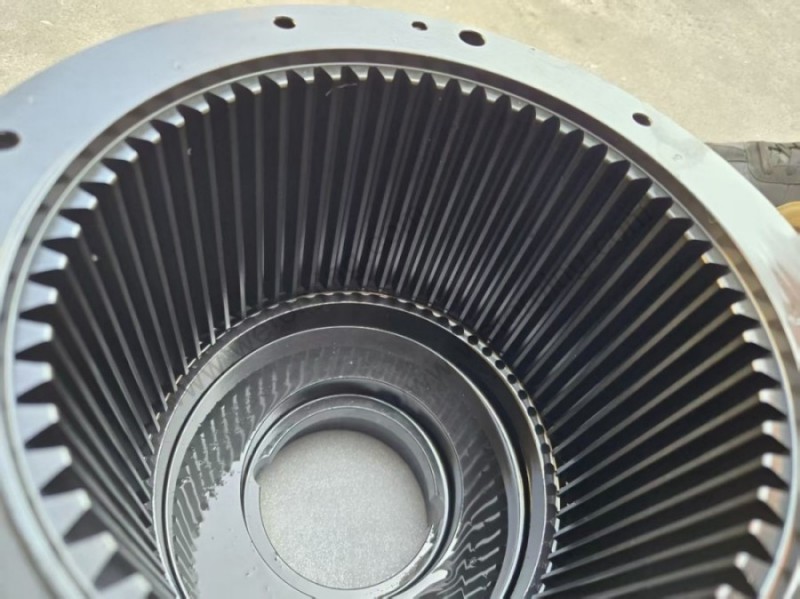

Precision Inner Ring Forgings for Heavy-Duty Industrial Applications

High-Strength Components Engineered for Performance & Reliability

Manufactured to the highest quality standards, our inner ring forgings deliver exceptional durability and precision for demanding mechanical systems. Forged from premium alloy steels and rigorously heat-treated, these components ensure superior strength, wear resistance, and dimensional accuracy in extreme operating conditions.

Key Features & Benefits

✔ Premium Material Construction

Forged from high-grade alloy steel (AISI 4140, 4340, 52100) or stainless steel

Precision heat treatment (quenching & tempering) for optimal hardness (HRC 32-58)

Ultrasonic tested for internal defects

✔ Precision Manufacturing

CNC machined to tight tolerances (ISO 2768-mK)

Ground or turned finishes available (Ra 0.8–3.2 μm)

100% dimensional inspection

✔ Superior Performance

High load-bearing capacity

Excellent fatigue resistance

Corrosion-resistant options available

✔ Customization Options

Diameters: 50 mm to 2000 mm

Custom wall thicknesses and profiles

Special surface treatments (black oxide, zinc plating)

Industrial Applications

Bearing assemblies

Gearbox components

Heavy machinery rotating elements

Wind turbine hubs

Mining equipment

Why Choose Our Inner Ring Forgings?

Certified Quality: ISO 9001:2015 compliant with full traceability

Performance Validation: Material test reports (MTRs) available

Global Standards: Meets ASTM, DIN, and JIS specifications

Fast Turnaround: Standard and custom sizes available