Sun Gear Explained: Role in Planetary Gear Systems

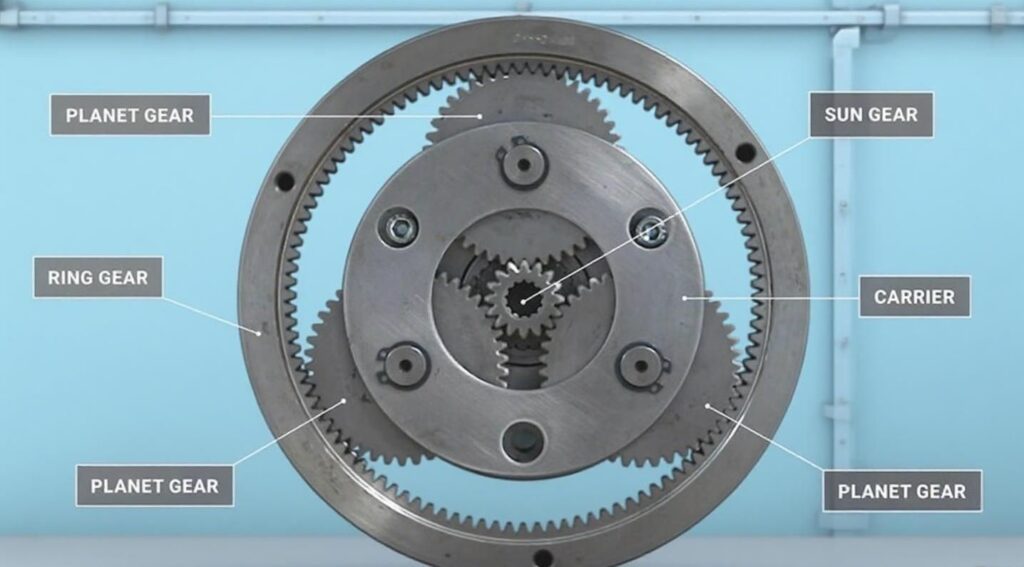

A sun gear is the central element of a planetary gear system, transmitting torque and guiding planet gear motion. Its compact design saves space and boosts efficiency, while its high load capacity supports demanding power transmission.

Sun gear applications include automotive transmissions, industrial machinery, wind turbines, and aerospace systems, where precision machining ensures strength, durability, and reliability. With rising demand for long-lasting components, forged sun gears continue to deliver smoother operation, energy savings, and extended service life across global industries.

What Exactly is a Sun Gear?

The sun gear is the central gear in a planetary system, directly engaging with surrounding planet gears. Its compact design enables efficient torque transmission, smoother operation, and improved performance. By distributing load evenly, it reduces stress and extends service life.

Planetary gear sets are widely used in automotive transmissions, hybrid systems, and heavy machinery, where compact size and high performance are critical. The sun gear drives the planet gears, regulates speed ratios, and optimizes power distribution, ensuring durability, efficiency, and stability in industries from automotive to aerospace.

How Does a Sun Gear Work?

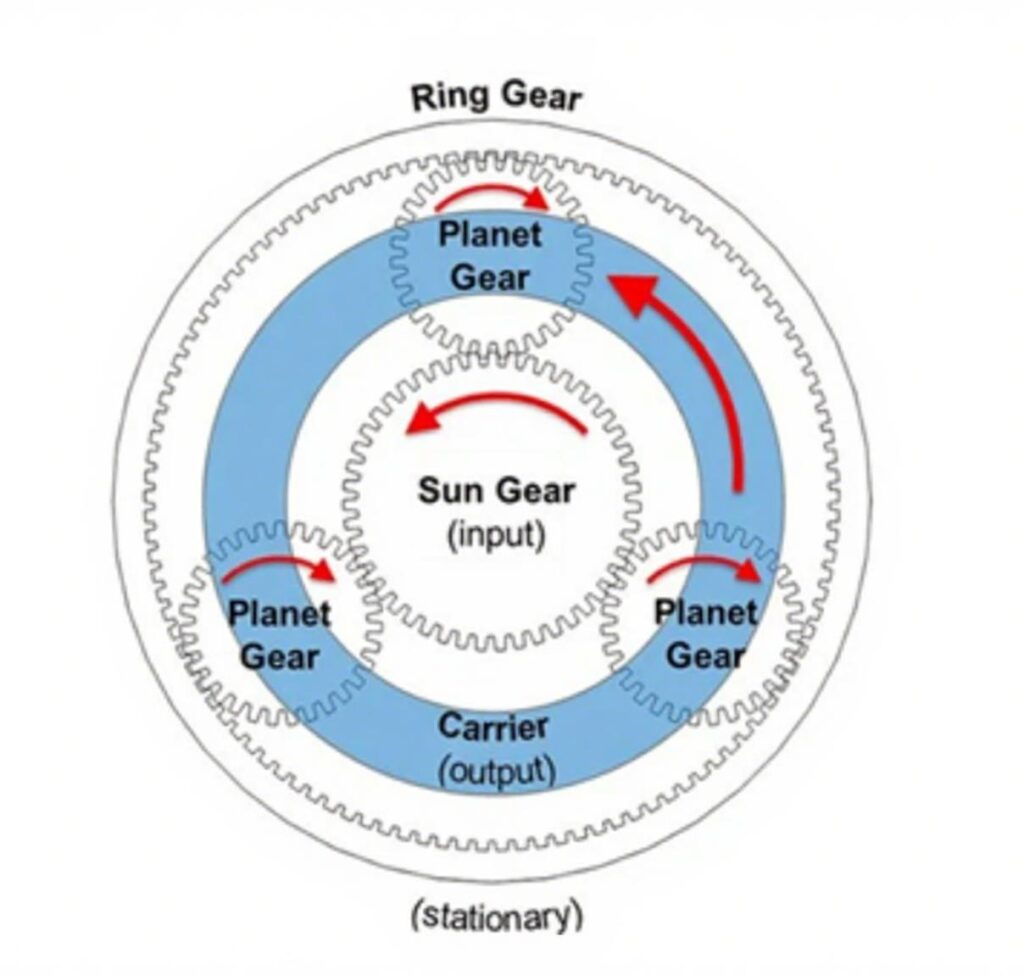

The sun gear function is to transmit torque from the input shaft to the surrounding planet gears, which then rotate and distribute power through the carrier. Depending on the configuration, this mechanism can increase torque, adjust speed ratios, or alter rotational direction, making it a highly versatile solution in modern power transmission.

In automotive transmissions, the sun gear works seamlessly with carriers and clutches to enable smooth gear shifts and balanced power flow. Moreover, in heavy-duty equipment such as cranes and excavators, it ensures reliable performance under demanding loads. Wind turbines also rely on sun gears to transfer rotational energy from the blades to the generator, thereby improving efficiency and system stability. Across these diverse applications, the sun gear remains a vital element of the planetary gear system, ensuring strength, durability, and long service life.

Where Are Sun Gears Used?

Sun gears are widely used across different industries and play a vital role in reliable power transmission:

- Automotive – Essential in automatic transmissions and hybrid drive systems, where smooth shifting and efficiency are critical.

- Industrial Machinery – Found in gearboxes, excavators, and heavy-duty equipment that operate under high loads.

- Wind Power – Integral to turbines, enabling consistent performance and long service life.

- Aerospace – Designed for lightweight yet high-strength gear systems to meet strict safety standards.

In many mechanical assemblies, sun gears are paired with other precision components to enhance system stability. For infrastructure and engineering projects, solutions such as our bridge forging supplier projects.

How Weforging Manufactures Sun Gears

At Weforging, sun gears are produced through a carefully controlled, integrated process that ensures strength, accuracy, and long service life:

Forging – High-quality blanks are formed using advanced hot forging and cold forging techniques to guarantee density and durability.

Machining – Precision CNC cutting and shaping create accurate gear teeth and smooth finishes.

Heat Treatment – Processes such as quenching and tempering improve hardness, wear resistance, and fatigue strength.

Testing – Comprehensive inspections, including CMM measurement, ultrasonic and magnetic testing, metallographic analysis, and hardness checks, ensure every gear meets strict quality standards.

We also supply precision forged gears for industries where accuracy and durability are critical. Learn more in our gears and shafts products.

Why Choose Weforging for Sun Gears

Choosing Weforging means partnering with a trusted forged gear manufacturer recognized worldwide.

Strength and Durability – Forged gears provide higher performance and longer life than cast gears.

High Precision – Advanced CNC machining ensures tight tolerances and consistent accuracy.

Industry Expertise – Proven across automotive, energy, heavy machinery, and aerospace applications.

Customization – From small precision gears to large wind power components, tailored to customer needs.

In addition, we provide complete mechanical assembly services, integrating gears and fasteners into turnkey solutions. This end-to-end capability enhances efficiency, reduces lead time, and ensures superior reliability for critical applications.

Conclusion

The sun gear is the driving force of planetary gear systems, delivering torque, enabling speed control, and ensuring stable performance. From cars to wind turbines and aerospace projects, it remains vital.

At Weforging, we specialize in forged and machined sun gears, backed by strict quality processes and customization options. Explore our products or contact our experts to find solutions for your projects.