Project Case Studies of Custom Forged Components

At Weforging, we support OEM customers with custom forged components for infrastructure, marine, transportation, energy, and aerospace applications. These project case studies demonstrate our capability in forging process design, hot forging production, CNC machining, heat treatment, and full inspection. From prototype development to long-term batch supply, we deliver stable quality and reliable manufacturing solutions.

Industry Coverage

Infrastructure & Large-Scale Construction

Marine & Offshore Equipment

Transportation & Heavy Machinery

Energy, Mining & Industrial Systems

Aerospace & High-Performance Applications

Each project reflects specific material, process, and quality requirements.

Selected Project Cases

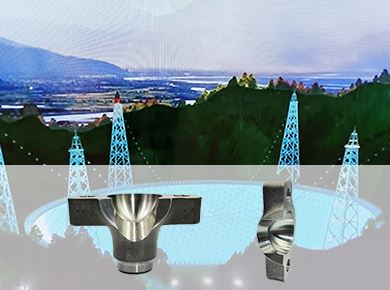

FAST Tianyan Forging Project

Large structural forged components for scientific infrastructure, delivered with controlled grain flow and stable mechanical performance.

View Project →

Yacht Cruise Forging Project

Precision forged components for marine and yacht systems, combining corrosion-resistant materials with CNC machining accuracy.

View Project →

HK–Zhuhai–Macao Bridge Forging Project

High-load forged fasteners and structural parts engineered for long-term infrastructure reliability.

View Project →

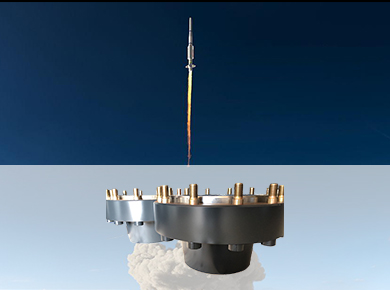

Aerospace System Forging Project

High-strength precision forgings manufactured under strict process control and inspection standards for aerospace systems.

View Project →

Why These Projects Matter

These projects demonstrate Weforging’s ability to manage complex forging requirements, tight tolerances, and long-term supply programs. Our integrated manufacturing model helps OEM customers reduce supplier coordination while maintaining consistent quality and delivery reliability.

Manufacturing Capabilities Summary

CNC turning, milling & drilling

Dimensional, mechanical & NDT inspection

Contact

Looking for a forging supplier with proven project experience?

Send us your drawings or specifications — our engineering team is ready to support your next project.