How Forged Components Lower Total Cost in Heavy-Duty OEM Programs

In heavy-duty OEM programs, cost evaluation extends beyond unit price. Components used in construction machinery, mining equipment, and industrial systems often operate under long service cycles, where manufacturing decisions made early in the project influence long-term operating and maintenance costs. As a result, forged components cost is increasingly evaluated from a total cost of ownership perspective rather than as a standalone manufacturing expense.

This article explains how forged components contribute to cost efficiency across the full lifecycle of heavy-duty OEM programs. By examining manufacturing, performance, and sourcing considerations together, OEM teams can better understand when forged components support long-term cost control and stable project execution.

Understanding Total Cost of Ownership in Heavy-Duty OEM Programs

Total cost of ownership in heavy-duty OEM programs includes more than initial manufacturing cost. It typically covers production, machining, inspection, installation, maintenance, and service-related expenses over the component’s operating life. For long-life equipment, these cost elements often outweigh the initial purchase price.

OEM procurement and engineering teams increasingly evaluate manufacturing routes based on how they influence lifecycle cost stability. Manufacturing consistency, predictable performance, and reduced variability all contribute to better long-term cost planning.

Forged vs Cast Components Cost: A Lifecycle Perspective

When comparing forged vs cast components cost, OEMs typically evaluate more than initial manufacturing expense. From a lifecycle perspective, differences in manufacturing consistency, performance stability, and downstream coordination influence long-term cost behavior across heavy-duty applications.

Cost Factor | Forged Components | Cast Components |

Initial manufacturing cost | Influenced by material processing and forging route | Influenced by mold design and casting setup |

Material utilization | Controlled material flow supports efficient use | Geometry flexibility may affect material efficiency |

Machining efficiency | Forged blanks often support stable machining paths | Machining allowance depends on casting geometry |

Performance consistency | Supports predictable behavior under load | Performance varies based on design and application |

Maintenance and service planning | Enables stable maintenance intervals | Service planning depends on operating conditions |

Lifecycle cost stability | Supports long-term cost predictability | Lifecycle cost varies by application scenario |

From a total cost of ownership perspective, OEMs assess how these factors interact over the full service life rather than viewing manufacturing cost in isolation.

For a broader discussion on how forging and casting differ in terms of process and performance, see Forging vs Casting: How OEMs Choose for Heavy-Duty Parts

How Forged Components Support Lower Lifecycle Cost

Before evaluating how forged components support lower lifecycle cost, it is important to understand how OEMs approach forging process selection during early project planning. Manufacturing routes defined at this stage influence material behavior, machining coordination, and inspection planning, all of which affect long-term cost performance.

From a lifecycle cost perspective, forged components are often evaluated based on how they support long-term performance stability and manufacturing consistency in heavy-duty OEM programs.

- Stable mechanical performance over long service periods

Controlled material flow supports consistent behavior under operating loads, helping OEMs plan maintenance with confidence. - Predictable maintenance and replacement planning

Performance consistency enables clearer service intervals and supports long-term lifecycle cost management. - Efficient integration with machining and inspection

Forged components align well with downstream machining and quality control processes, reducing variability over time. - Manufacturing consistency across project lifecycles

Coordinated forging, machining, and inspection routes support predictable cost performance in heavy-duty applications.

Together, these factors help OEM teams manage lifecycle cost more predictably across the full service life of heavy-duty components.

Manufacturing Efficiency and Cost Control in Forged Components

Manufacturing efficiency plays an important role in forged components cost. Well-defined forging blanks support efficient machining by reducing unnecessary material removal and stabilizing machining paths.

In coordinated manufacturing routes, forging and machining are planned together, helping control processing time and resource allocation. This integration supports consistent production outcomes and cost predictability.

Cost Benefits of Forged Components in Project-Based OEM Programs

In project-based OEM programs, production volumes are often moderate and specifications may evolve during early stages. Forged components support this environment by offering flexibility in geometry and material selection without relying on highly specialized tooling.

This flexibility helps OEMs manage cost allocation across project phases while maintaining manufacturing consistency. As a result, forged components can support stable budgeting and execution in project-driven programs.

When Forged Components Make Economic Sense for OEMs

Forged components often make economic sense for OEMs in the following situations:

- Heavy-duty components subjected to continuous or cyclic loads

- Programs with long service life and maintenance-sensitive cost structures

- Project-based manufacturing requiring flexible geometry and stable execution

- Applications where manufacturing consistency supports long-term cost planning

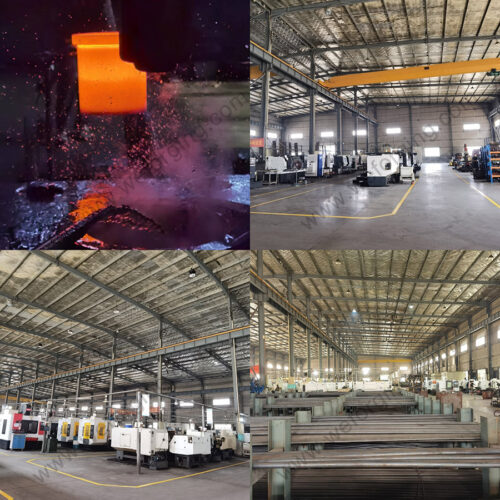

Why OEMs Value Integrated Manufacturing Partners

For heavy-duty OEM programs, integrated manufacturing partners support cost control and component service life by coordinating forging, heat treatment, and machining within a single production system. This structure improves process alignment, material consistency, and traceability across manufacturing stages.

By reducing supplier handoffs and aligning production with inspection planning, integrated manufacturing helps OEM teams manage quality requirements more efficiently. This approach supports stable project execution and more predictable lifecycle cost performance.

Evaluating Forging Suppliers from a Total Cost Perspective

Supplier evaluation plays an important role in total cost control for heavy-duty OEM programs. From a total cost perspective, OEMs typically assess forging suppliers based on the following aspects:

- Manufacturing capability and process coverage

The ability to support required forging methods, component sizes, and material grades. - Quality systems and inspection support

Quality management, testing, and inspection capabilities aligned with OEM standards. - Production coordination and delivery planning

Clear planning across forging, machining, and inspection to support predictable execution. - Technical communication and documentation

Effective communication and complete documentation throughout the project lifecycle.

Suppliers that integrate forging, machining, inspection, and documentation within a coordinated manufacturing plan are better positioned to support stable and predictable cost performance.

Conclusion

Forged components cost should be evaluated within the broader context of total cost of ownership in heavy-duty OEM programs. While unit price is one consideration, manufacturing consistency, lifecycle performance, and sourcing coordination often have a greater influence on long-term cost outcomes. By assessing these elements together, OEMs can make manufacturing decisions that support stable execution and cost efficiency across the full project lifecycle.

If you are reviewing forged component options for a specific OEM program, our team is available to discuss technical requirements and manufacturing approaches. You are welcome to contact us for a free consultation, with responses typically provided within 24 hours.