Forged vs Machined Parts: Which Performs Better?

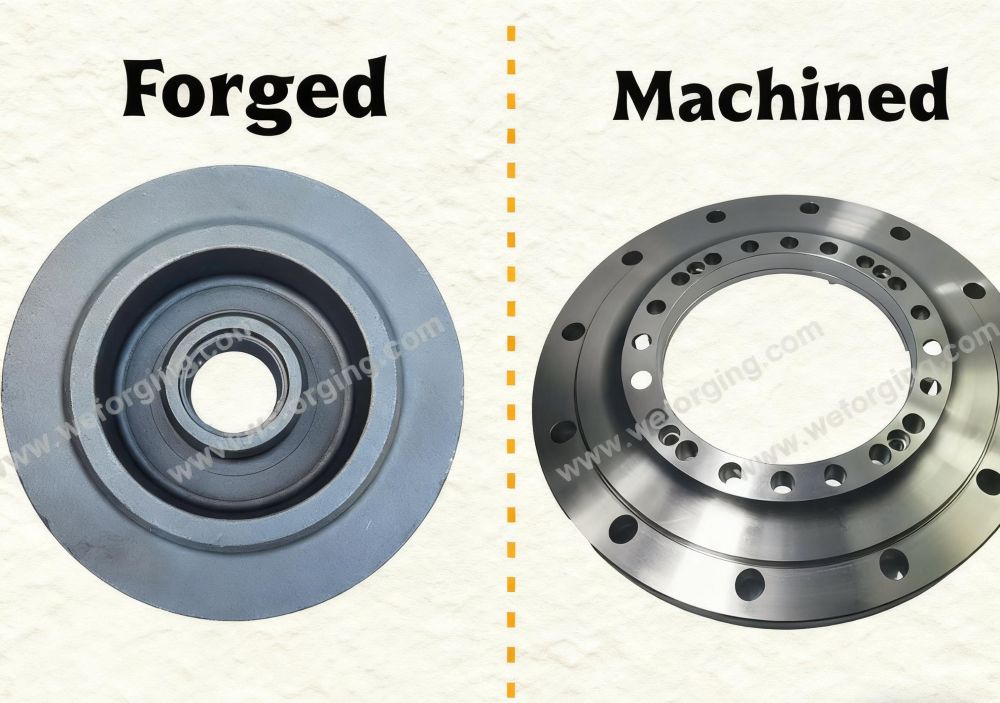

In precision manufacturing, comparing forged and machined parts often centers on performance factors such as strength, accuracy, and cost efficiency. Forging enhances the internal grain structure through plastic deformation, improving toughness and fatigue resistance. Machining, on the other hand, removes material with precision tools to achieve complex geometries and tight tolerances.

In modern production, both methods are frequently combined — forged blanks are CNC machined to meet final dimensional and surface requirements. This integration ensures reliable mechanical properties and high-precision results for critical industrial components.

What Are Forged Parts?

Forged parts are manufactured by shaping heated metal billets under controlled pressure, a process known as forging. During deformation, the grain flow aligns with the geometry of the part, forming a dense and uniform internal structure. This directional grain pattern significantly enhances tensile strength, fatigue resistance, and impact toughness, outperforming cast or fully machined materials.

Because of these benefits, forged steel components are commonly used in applications that demand high strength and durability, such as shafts, gears, flanges, and connecting parts. When followed by CNC machining, forged blanks achieve both mechanical integrity and precise dimensional accuracy, ensuring dependable performance in automotive, energy, and heavy machinery industries.

What Are Machined Parts?

Machined parts are made by removing material from a solid workpiece with precision cutting tools and CNC machining systems. This process delivers tight dimensional tolerances, smooth surface finish, and the ability to create complex shapes. Controlled cutting speed, tool geometry, and coolant flow ensure consistent accuracy in every batch.

In modern manufacturing, CNC machining is often applied to pre-forged blanks to achieve final dimensions and functional surfaces. The result is a forged and machined component that combines the structural strength of forging with the precision of machining — ideal for automotive, aerospace, energy, and heavy equipment applications.

Forged vs Machined Parts: Key Differences

Aspect | Forged Parts | Machined Parts |

Manufacturing Method | Deformation under pressure | Material removal by cutting |

Grain Structure | Continuous and refined | Interrupted and directional |

Strength & Durability | High fatigue and impact strength | Excellent precision, moderate strength |

Dimensional Accuracy | High | Very high |

Material Utilization | Up to 90% | Lower due to chip waste |

Ideal Applications | Shafts, gears, flanges | Fittings, housings, tools |

When Forging and Machining Work Together

In modern manufacturing, the combination of forging and machining has become the preferred method for achieving both strength and precision. Typically, a forged blank is produced to near-net shape and then refined through CNC machining to reach the final geometry and surface finish. This process, known as precision machining after forging, not only ensures dimensional accuracy but also maintains the superior mechanical properties formed during forging.

At Weforging, forged shafts, flanges, and gear components are processed on Mazak CNC machining centers equipped with multi-axis capability and real-time inspection systems. Each part achieves tight tolerances within ±0.01 mm and a surface roughness up to Ra ≤ 1.6 µm.This integrated workflow minimizes material waste, reduces secondary processing, and delivers components with consistent quality and repeatability

Advantages of Forged and Machined Components

- High mechanical strength with consistent geometry

- Superior fatigue and impact resistance

- Reduced material waste and better cost efficiency

- Excellent surface finish and tolerance control

- Reliable performance for OEM assemblies

Applications Across Industries

Forged and machined components are essential in sectors that demand both structural strength and dimensional accuracy. Their ability to withstand high loads, vibration, and fatigue makes them indispensable in modern engineering systems.

- Automotive: Used in transmission shafts, connecting rods, differential gears, and hub flanges, forged and machined parts ensure reliability under continuous torque transmission. For example, leading OEMs such as Volvo and Caterpillar use forged shafts for durability in heavy-duty vehicles.

- Wind & Energy: Turbine shafts, forged flanges, and bearing housings provide high integrity under rotational and thermal stress. Wind turbine manufacturers like Siemens Gamesa rely on forged flanges for tower connections that must resist cyclic loading.

- Heavy Machinery: Components such as gear hubs, rollers, couplings, and drive axles operate under intense mechanical loads. Forged steel structures deliver long service life in excavators, cranes, and industrial presses.

- Marine & Mining: Anchor rings, propeller shafts, and forged bolts maintain safety in corrosive or high-impact environments, making them vital for offshore platforms and mining equipment.

Conclusion

Forged parts provide exceptional structural strength and fatigue resistance, while machined parts deliver superior dimensional precision and surface finish. When combined, forged and machined components achieve the optimal balance of strength, accuracy, and reliability — the foundation of performance-critical industrial systems.

At Weforging, we integrate forging, CNC machining, heat treatment, and quality testing under one roof. This unified process ensures consistent standards, full traceability, and dependable results for global OEM clients.

Looking for customized forged or machined components?

Contact our engineering team today to discuss your project requirements or request a quotation.

F.A.Q.

Forged parts offer higher strength, fatigue resistance, and grain uniformity than fully machined components. Because forging refines the internal metal flow, the structure becomes denser and better aligned with the load path, reducing the risk of cracks or deformation. In contrast, machined parts excel in precision and surface finish, making both methods complementary in modern manufacturing.

Yes. In many cases, cast parts can be replaced by forged parts to improve strength, fatigue resistance, and reliability. Casting allows complex shapes but may include internal defects such as porosity or shrinkage, while forging produces a denser structure with refined grain flow.

At Weforging, we offer custom casting-to-forging conversion services, helping OEM clients upgrade cast components into stronger forged alternatives. Our engineers evaluate design and load conditions to deliver tailored forging solutions for improved performance in applications such as automotive gears, flanges, and shafts

The choice depends on your design requirements and functional priorities. For parts needing high strength and impact resistance — such as shafts, gears, or flanges — forging followed by CNC machining is ideal. For smaller components demanding tight tolerances or complex geometry, CNC machining alone may be more efficient. At Weforging, engineers often combine both to achieve cost-effective, high-performance OEM solutions.