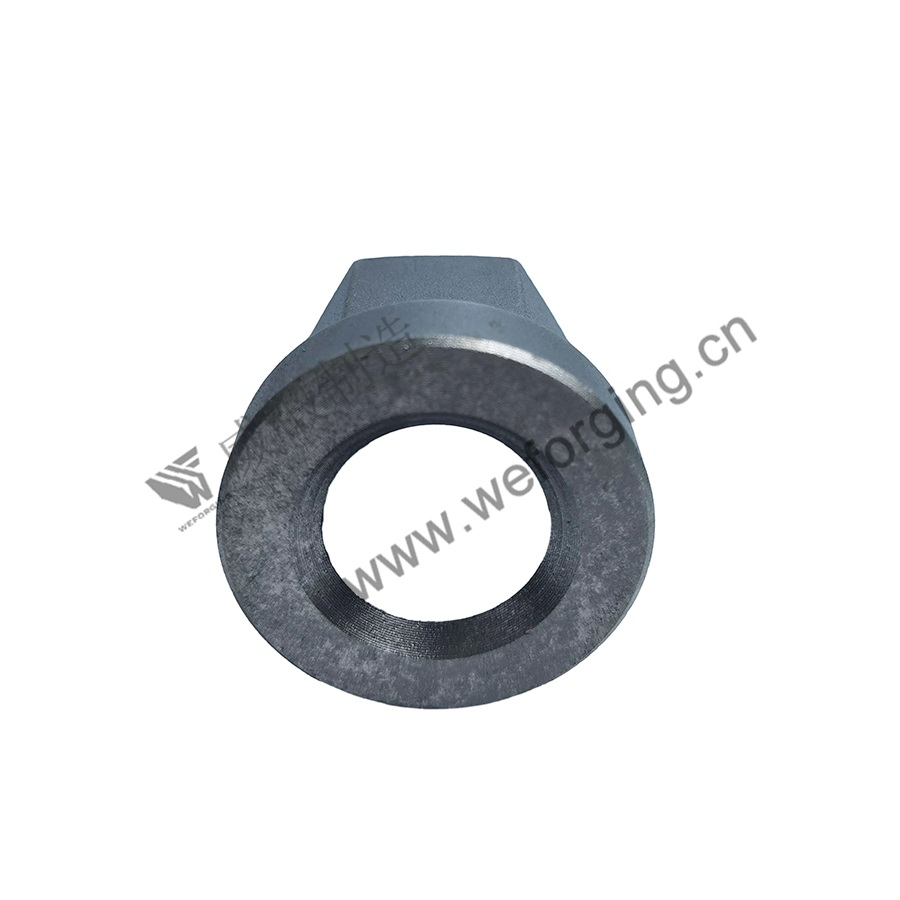

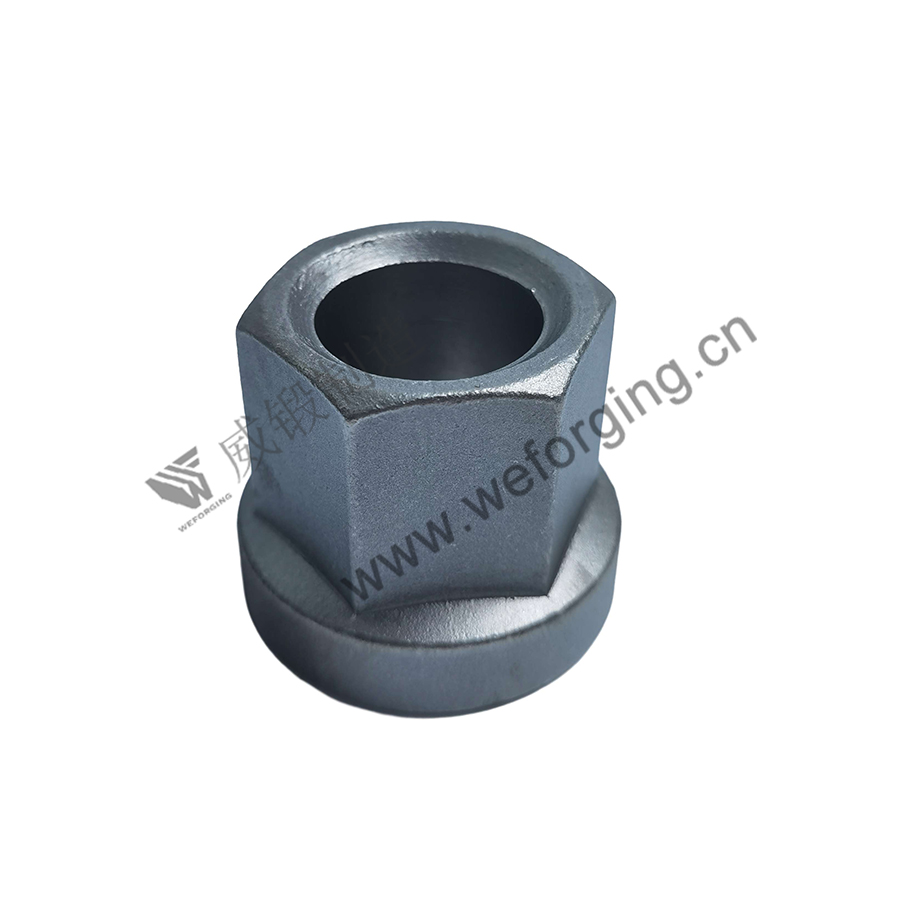

Hot Forged Hex Nut | Heavy-Duty Hex Nuts

A hex nut is one of the most widely used fasteners in mechanical assemblies, known for its versatility, strength, and reliable threaded connection. Weforging specializes in hot forged hex nuts designed for high load capacity, stable tightening performance, and long service life. Manufactured through controlled forging, precision machining, and strict quality testing, our hex nuts deliver excellent consistency for demanding industrial applications. Whether you require standard sizes or customized dimensions, we support global OEM customers with flexible and efficient production solutions.

What Is a Hex Nut?

A hex nut is a six-sided fastener used together with bolts or threaded rods to secure mechanical components. Its geometric shape ensures easy wrenching from multiple angles and offers high torque resistance.

Compared with other nut types, hex nuts provide a balanced combination of strength, simplicity, and cost-efficiency. Heavy-duty versions, such as heavy hex nuts, are used when higher preload and structural strength are required.

They are commonly measured by industry standards, including hex nut sizes defined in DIN, ISO, ANSI, and GB specifications.

Manufacturing Process

Weforging’s hex nuts are produced through a fully controlled hot forging process to ensure superior density and mechanical reliability:

Raw material cutting

Induction heating and die forging

Flash removal and trimming

CNC machining for threads and surfaces

Heat treatment for increased hardness and strength

Surface finishing (zinc plating, black oxide, Dacromet, etc.)

100% inspection before shipment

This process guarantees uniform shape, stable dimensions, and excellent load-bearing capability.

Materials & Grades

We offer a wide range of materials to meet different working conditions:

Carbon steel: Q235, 45#

Alloy steel: 40Cr, 42CrMo, SCM435

Stainless steel: 304, 316 (stainless steel hex nuts)

Strength grades: 8, 10, 12

Custom materials and coatings are also available upon request.

Specifications & Sizes

Our production covers nearly all standard and non-standard dimensions:

Standards: DIN934, DIN6915, ISO4032, ANSI/ASME

Size range: M6–M48 (customizable)

Optional type: hex flange nut, slotted nut, heavy hex nut

We also provide engineering support for heavy hex nut dimensions based on drawings or samples.

Key Performance Advantages

Thanks to high-density forging and optimized machining, Weforging’s hex nuts offer:

Strong load capacity and stable tightening performance

High thread precision and smooth assembly

Excellent wear resistance after heat treatment

Corrosion protection with multiple surface treatment options

Reliable performance across heavy-duty and continuous operation environments

These characteristics make our hex nuts dependable components in industrial fastening systems.

Applications

Our forged hex nuts are widely used in:

Construction machinery

Power generation and structural assemblies

Industrial machinery and hex bolts and nuts fastening systems

They ensure reliable clamping force even under vibration, shock, and variable loads.

Why Choose Weforging

With advanced forging equipment and a professional engineering team, we provide:

High-strength forged fasteners with consistent quality

Standard and customized production flexibility

Quick lead time and stable supply capacity

Complete testing: hardness, thread gauge, material certification

Contact Us

If you need high-quality hex nuts or custom-designed fasteners, our engineering team is ready to support your project.

Contact us for drawings, quotations, or technical consultation.