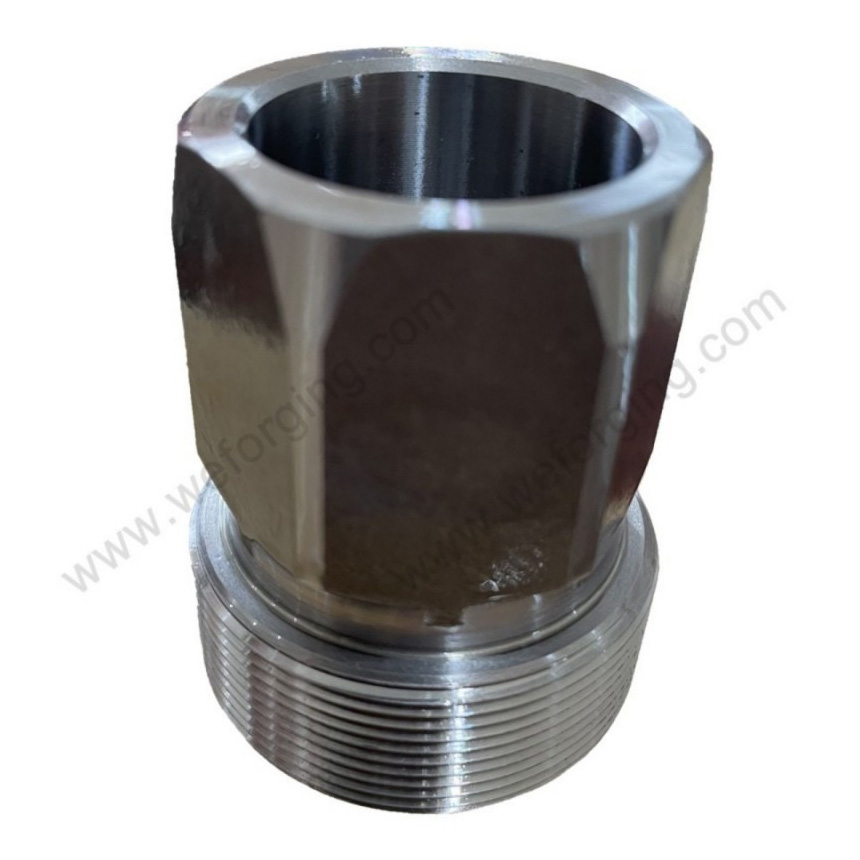

Precision Drive Nuts for Power Transmission

Drive nut forgings are precision-engineered components designed to transfer torque and axial force in hydraulic cylinders, mechanical actuators, and industrial assemblies. Produced through closed-die forging and CNC machining, each forged drive nut achieves excellent dimensional accuracy and structural density. This ensures stable performance, uniform thread fit, and long service reliability under heavy mechanical load.

What Is a Drive Nut

A drive nut is a precision-engineered component that converts rotational motion into linear force, widely applied in power transmission systems, hydraulic assemblies, and mechanical linkages. Unlike conventional nuts, drive nuts are forged and CNC-machined to withstand higher torque and axial loads with consistent accuracy.

Their threaded or slotted design ensures precise alignment and efficient torque transfer, supporting stable mechanical performance. Therefore, during manufacturing, drive nut forgings are produced through closed-die forging, which refines the internal grain structure and enhances strength and durability for long-term operation

Manufacturing Process

- Material Selection: High-quality alloy or carbon steel (such as 42CrMo, 4140, or SCM440) is carefully selected for its strength and durability, ensuring stable performance in demanding applications.

- Closed-Die Forging: Heated billets are precisely forged under controlled pressure to create dense, uniform grain flow, resulting in superior structural integrity and load capacity.

- CNC Machining: Threads, flats, and shoulder surfaces are accurately machined to achieve perfect engagement and efficient torque transfer between components.

- Heat Treatment: Normalizing, quenching, and tempering processes are applied to balance hardness, toughness, and mechanical stability for long-term reliability.

- Inspection: Each drive nut forging is verified through dimensional, hardness, and visual inspections in accordance with ISO 9001:2015 standards to ensure consistent quality.

Advantages of Drive Nut

Drive nut forgings deliver high strength, precise dimensions, and dependable assembly performance. The forged structure enhances load capacity and service life, while CNC machining ensures accurate thread geometry and stable tolerance control. Each nut supports smooth torque transfer and secure locking during use. Available in alloy, carbon, and stainless steel, they perform reliably across diverse industrial environments.

Applications

Drive nut forgings are widely used in heavy-duty and hydraulic applications, including:

Industrial locking and clamping assemblies

OEM mechanical structures requiring precision torque transfer

Why Procurement Managers Choose Weforging

Procurement professionals select Weforging for its integrated forging + CNC + testing process, ensuring full quality traceability. Our in-house tooling and inspection systems guarantee consistent thread profiles, precise dimensions, and reliable delivery schedules. Every forged drive nut is supported by comprehensive test documentation, including hardness, UT/MPI, and dimensional reports — helping global buyers reduce rework and improve production stability.

Contact

Weforging provides custom drive nuts with flexible materials, sizes, and thread standards.

Our engineering team offers full support from design to production, ensuring perfect fit and fast delivery.

➡ Contact us today to discuss your project or request a quotation.