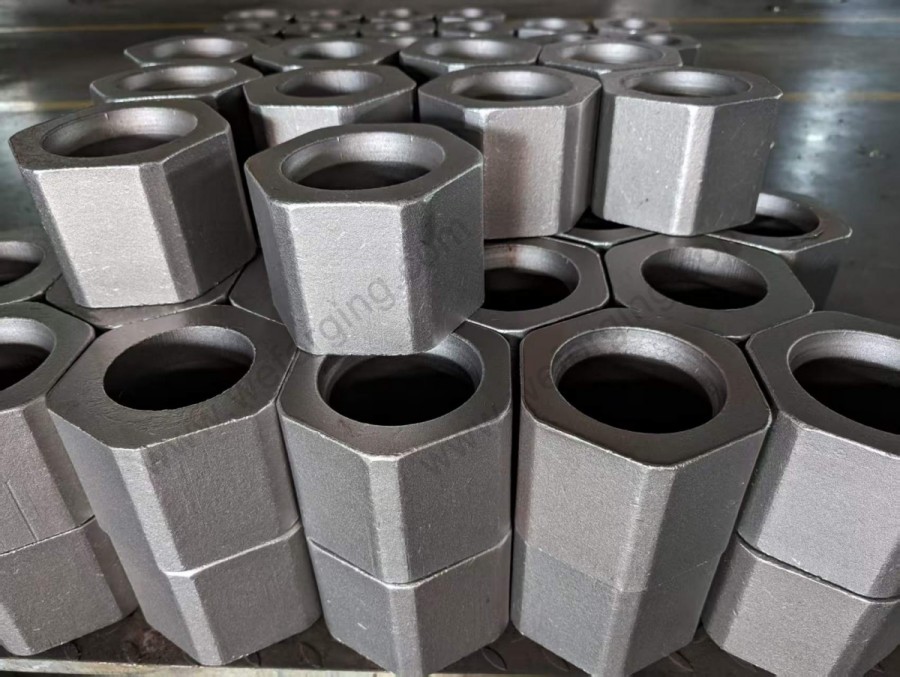

Forged Heavy Hex Nut

Weforging manufactures precision forged heavy hex nuts through an integrated forging + CNC machining + testing process. Designed for high-strength fastening and stability, these nuts ensure excellent load capacity and dimensional precision. Moreover, our ISO-certified system guarantees consistent quality in every batch. In addition, materials such as 35CrMo, 42CrMo, and stainless steel provide enhanced durability and corrosion resistance. Each nut is engineered for optimal torque performance and long-term reliability.

Manufacturing Process

Every forged heavy hex nut from Weforging follows a carefully managed process designed for precision, strength, and durability. The workflow integrates forging, machining, and inspection to ensure consistent results at every stage:

Hot Forging: Selected billets are heated and forged under controlled temperature and pressure, refining grain flow and improving mechanical properties.

CNC Machining: Each nut is precisely milled and threaded to guarantee uniform hex geometry and accurate fit.

Heat Treatment: Controlled quenching and tempering increase hardness and fatigue resistance while maintaining structural balance.

Surface Treatment: Finishes such as zinc plating, black oxide, or phosphate coating improve corrosion resistance and visual uniformity.

Final Inspection: CMM dimensional checks, hardness verification, and ultrasonic testing confirm the integrity and consistency of every batch.

This comprehensive production flow ensures Weforging’s nuts maintain reliable torque resistance and dimensional accuracy for demanding applications.

Advantages of Heavy Hex Nuts

Weforging’s forged heavy hex nuts combine engineering precision with superior strength. The forging process enhances grain density, resulting in improved tensile strength and uniform load distribution. Moreover, CNC machining ensures precise thread engagement and repeatable assembly performance. Controlled heat treatment enhances surface hardness while maintaining ductility, and optional coatings improve corrosion resistance in harsh environments. In addition, we offer full customization in size, thread pitch, and material grade to meet OEM requirements across industries.

Applications

Weforging’s heavy hex nuts are trusted across industries that demand strength, stability, and reliability. Their forged integrity and precision machining make them ideal for:

Wind Power Systems: Securing tower flanges and nacelle connections under variable torque and vibration.

Heavy Machinery: Fastening critical joints in shafts, gears, and frame structures for stable load transfer.

Construction and Bridge Engineering: Providing reliable fastening for steel frames, cranes, and modular assemblies.

Oil & Gas Equipment: Performing under extreme pressure and temperature fluctuations while maintaining sealing integrity.

Mining and Industrial Equipment: Supporting hydraulic systems and structural joints that require high endurance.

These versatile applications highlight Weforging’s ability to deliver fastening solutions that perform consistently under real-world operating conditions.

Conclusion

Combining hot forging precision, CNC machining accuracy, and full-process testing, Weforging’s heavy hex nuts offer reliable fastening performance for critical applications. Each nut is designed for long-term structural integrity, corrosion resistance, and dimensional accuracy.

Looking for high-performance forged heavy hex nuts for your next project?

Weforging provides complete engineering support—from material selection to mass production—ensuring each nut matches your technical and quality expectations.