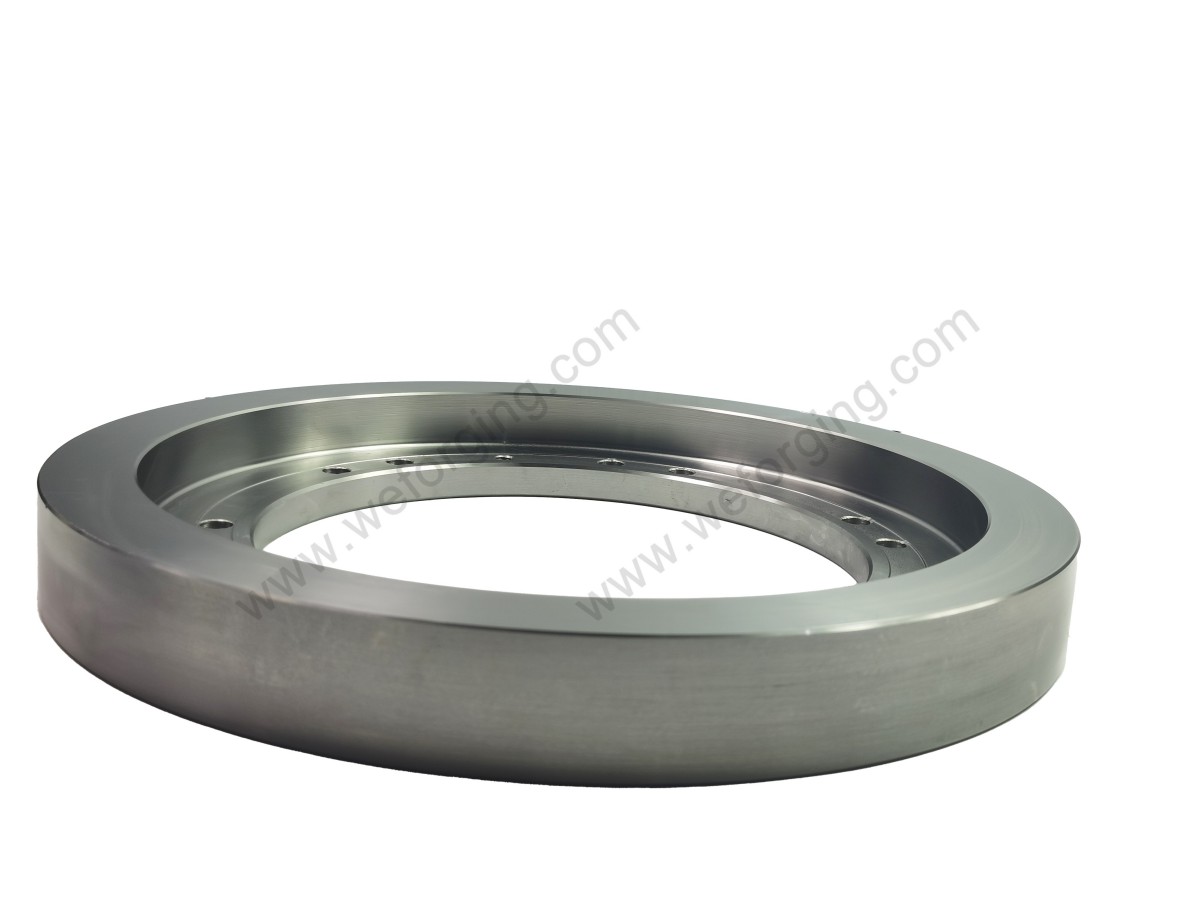

Forged Steel Structural Ring | Ring Rolled & CNC Machined

A forged steel structural ring is a key load-bearing component widely used in industrial and mechanical systems. Manufactured through advanced ring rolling forging and precision CNC machining, Weforging’s custom forged steel rings offer continuous grain flow, optimized material performance, and accurate geometry. These features contribute to balanced load transfer and stable structural performance across construction machinery, industrial equipment, energy systems, and heavy-duty mechanical assemblies.

Ring Rolling Forging Process

Ring rolling forging is a seamless forming process in which a heated forged blank is expanded into a ring through controlled radial and axial rolling. This process creates a continuous circumferential grain flow that enhances structural integrity and supports uniform load transfer.

At Weforging, the typical process includes material preparation, controlled heating, pre-forging to form a dense ring blank, radial-axial ring rolling to achieve target dimensions, followed by controlled cooling, optional heat treatment, and CNC machining for final size and surface quality.

Structural Function and Performance

Forged steel structural rings are commonly used as supporting and load-distributing components within mechanical assemblies. Their seamless forged structure enables uniform force transfer, contributing to overall system stability and efficient operation.

Key performance highlights include:

High structural strength achieved through continuous grain flow

Dimensional stability supported by controlled heat treatment and machining

Consistent mechanical response under both static and dynamic loading conditions

Stable and dependable performance in continuous industrial operation

Together, these attributes make forged steel structural rings a strong choice for applications that benefit from balanced load distribution, precise dimensional control, and stable structural performance.

Materials and Custom Specifications

Weforging offers a wide selection of materials for forged steel structural rings, allowing flexibility across different operating conditions:

Common Materials

Carbon steel: C45, AISI 1045

Alloy steel: 42CrMo, 4140, 4340

Low-alloy structural steels

Stainless steel (available upon request)

Custom Specifications

Outer diameter and inner diameter ranges

Wall thickness and axial height

Heat treatment options such as normalizing or quenching & tempering

CNC machining tolerances according to application requirements

All forged steel rings are produced based on customer drawings, technical specifications, or approved samples.

Applications

Forged steel structural rings manufactured by Weforging are widely used in:

Structural support components in industrial machinery

Gearbox housings and mechanical assemblies

Rotating equipment and load-bearing systems

Construction and heavy-duty equipment structures

Energy and industrial processing equipment

Their structural reliability and customization flexibility make them suitable for both standard designs and project-specific applications.

Manufacturing Capability and Quality Control

Weforging operates an integrated manufacturing system covering forging, machining, and inspection. Each forged steel structural ring undergoes dimensional inspection, material verification, hardness testing, and ultrasonic testing when required, ensuring stable quality and traceable production for OEM programs.

Custom Forged Steel Structural Rings for OEM Projects

As an experienced forged steel ring manufacturer, Weforging supports OEM and industrial customers with drawing-based or sample-based customization. Products can be delivered as forged blanks, semi-finished rings, or fully machined components, depending on project requirements.

Our engineering team works closely with customers to optimize material selection, forging design, and machining strategies for each application.

Conclusion & Inquiry

Weforging’s custom forged steel structural rings provide reliable solutions for industrial applications requiring strength, stability, and dimensional consistency. With ring rolling forging expertise, precision CNC machining, and OEM-oriented manufacturing support, we are ready to assist your next project.

📩 Contact our team to discuss drawings, specifications, or custom forged steel structural ring requirements.