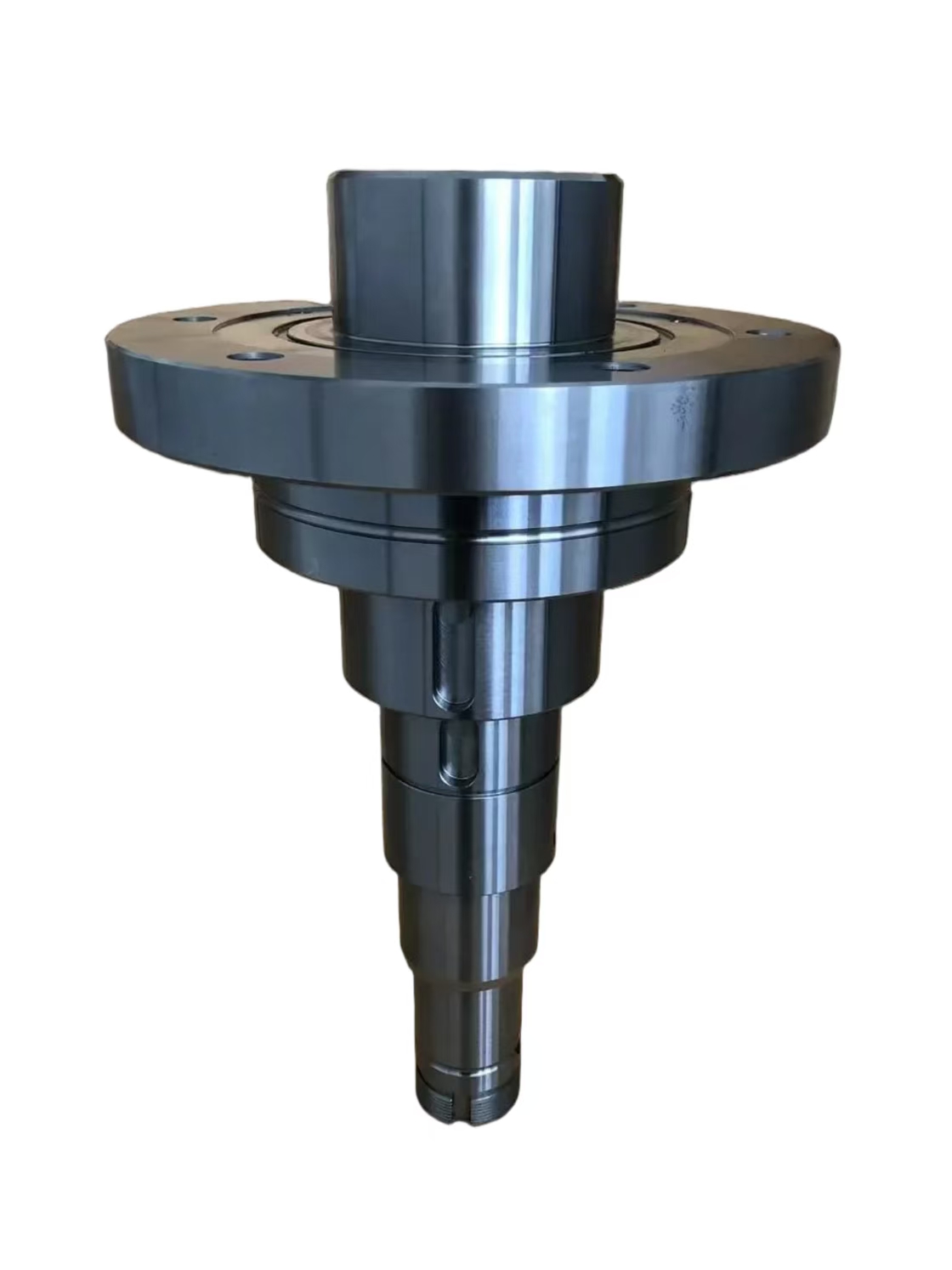

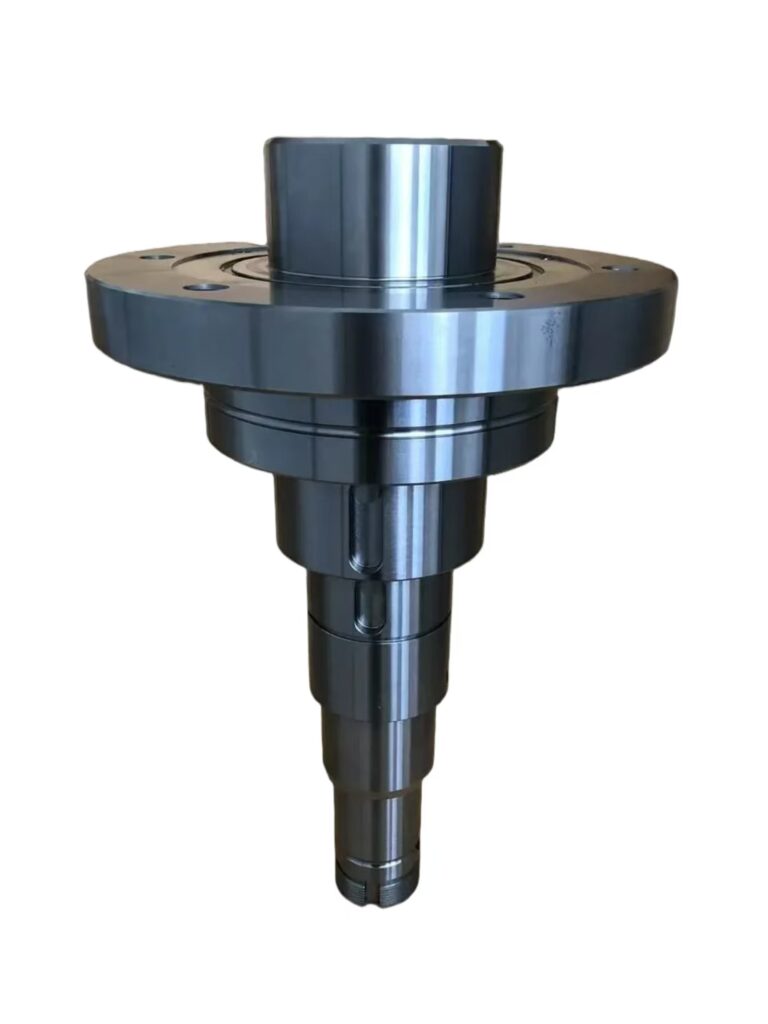

Precision Forged Steel Rotor Shafts

When turbine performance requires micron-level precision, Weforging’s precision forged rotor shafts serve as the foundation of reliable power transmission.Each shaft begins with a vacuum-degassed SAE 4340 alloy steel ingot, forged at approximately 2,200 °F (1,200 °C) to align the internal grain flow and enhance structural integrity.This controlled forging process produces a high-density, fatigue-resistant blank that delivers superior mechanical strength and balance.By integrating forging, CNC machining, and inspection under one quality system, Weforging ensures consistent reliability, long service life, and exceptional performance for heavy-duty industrial applications.

About Rotor Shafts

A rotor shaft is the rotating core component of turbines, generators, compressors, and heavy industrial equipment.It is designed to transfer torque and mechanical power with high precision and stability.Unlike conventional machined shafts, a forged rotor shaft is produced through controlled hot deformation, aligning the metal grain flow along the rotation axis.This process creates a dense, fatigue-resistant structure with excellent strength and balance, capable of operating reliably under high speed, high temperature, and heavy-duty conditions.

Materials & Heat Treatment for Forged Steel Rotor Shafts

Forged steel rotor shafts are manufactured from high-strength alloy steels selected according to torque, rotational speed, and service conditions. Typical material grades include:

42CrMo / AISI 4140 – Balanced strength and toughness for general heavy-duty applications

34CrNiMo6 – Enhanced toughness and fatigue resistance for dynamic and high-load conditions

AISI 4330 – Suitable for large rotor shafts requiring high core strength and stability

Heat treatment is applied to achieve the required mechanical properties and dimensional stability. Common heat treatment practices include:

Normalizing – To refine grain structure and improve material uniformity

Quenching & Tempering (Q&T) – To achieve specified strength, hardness, and fatigue resistance

Stress relieving (if required) – To minimize residual stress after forging or rough machining

Heat treatment processes are performed in accordance with applicable standards such as ASTM A29, ASTM A322, EN 10083, or customer-specified technical requirements.

Rotor Shaft Manufacturing Process

Billet Preparation:

High-quality alloy steel (42CrMo4, 4340) is cut and heated to about 1,200 °C to achieve proper forging temperature.Hot Forging:

The billet is forged under controlled pressure, aligning the grain flow along the shaft axis for superior strength and density.Heat Treatment:

Each forged shaft undergoes normalizing, quenching, and tempering to refine its microstructure and enhance mechanical properties.CNC Machining:

Precision machining on CNC turning and milling centers ensures tight tolerances, excellent concentricity, and smooth surfaces.Testing & Inspection:

Every rotor shaft is verified through ultrasonic testing, magnetic particle inspection, and CMM measurement, meeting ISO 9001:2015, AGMA, and ASTM standards.

Inspection & Quality Standards

Each forged steel rotor shaft is inspected to verify dimensional accuracy, internal integrity, and mechanical performance. Typical inspection and testing methods include:

Ultrasonic testing (UT) – Detection of internal defects

Magnetic particle inspection (MT) – Surface and near-surface crack inspection

Hardness testing – Verification after heat treatment

CMM measurement – Dimensional accuracy, concentricity, and geometric tolerance control

Manufacturing and inspection processes are conducted under an ISO 9001:2015 quality management system and aligned with applicable ASTM, EN, or AGMA standards to ensure traceability and batch consistency.

Applications & Industries

Typical applications include:

Turbines & Generators: Engineered for gas, hydro, and steam turbines to ensure smooth energy transfer and stable operation.

Compressors & Pumps: Perfect for industrial compressors, centrifugal pumps, and blowers that require precise alignment and rigidity.

Power & Energy Equipment: Suitable for generators, wind turbines, and power drives that operate under continuous torque and thermal variation.

Petrochemical Machinery: Forged alloy steel shafts designed for reactors, cracking units, and compressor systems working in elevated temperatures.

Mining & Heavy Machinery: Durable shafts for hydraulic drives, crushers, and gearboxes that demand consistent performance and load capacity.

Marine & Propulsion Systems: Anti-corrosive forged shafts for propellers, marine engines, and deck machinery in coastal and offshore environments.

OEM Customization & Engineering Support

Weforging provides forged steel rotor shafts based on customer drawings and application requirements. OEM support includes:

Drawing-based manufacturing

Material grade and heat treatment selection

Forging route and machining allowance optimization

Support for prototype and series production

This engineering-driven approach helps OEM customers achieve consistent quality, controlled risk, and reliable delivery across different project stages.

Conclusion

When comparing forged rotor shafts with conventional machined or cast shafts, the difference lies in performance and reliability. Forging refines the grain structure, enhances fatigue strength, and ensures superior concentricity—making it the preferred choice for high-torque, high-speed, and heavy-duty power systems.

With integrated forging + CNC machining + testing, Weforging provides fully customized rotor shaft solutions that comply with ISO 9001:2015, AGMA, and ASTM standards.

📩 Click the inquiry button below to upload your drawings or request a real-time quote. Our engineering team will review your specifications and reply with a detailed technical consultation and cost-effective proposal