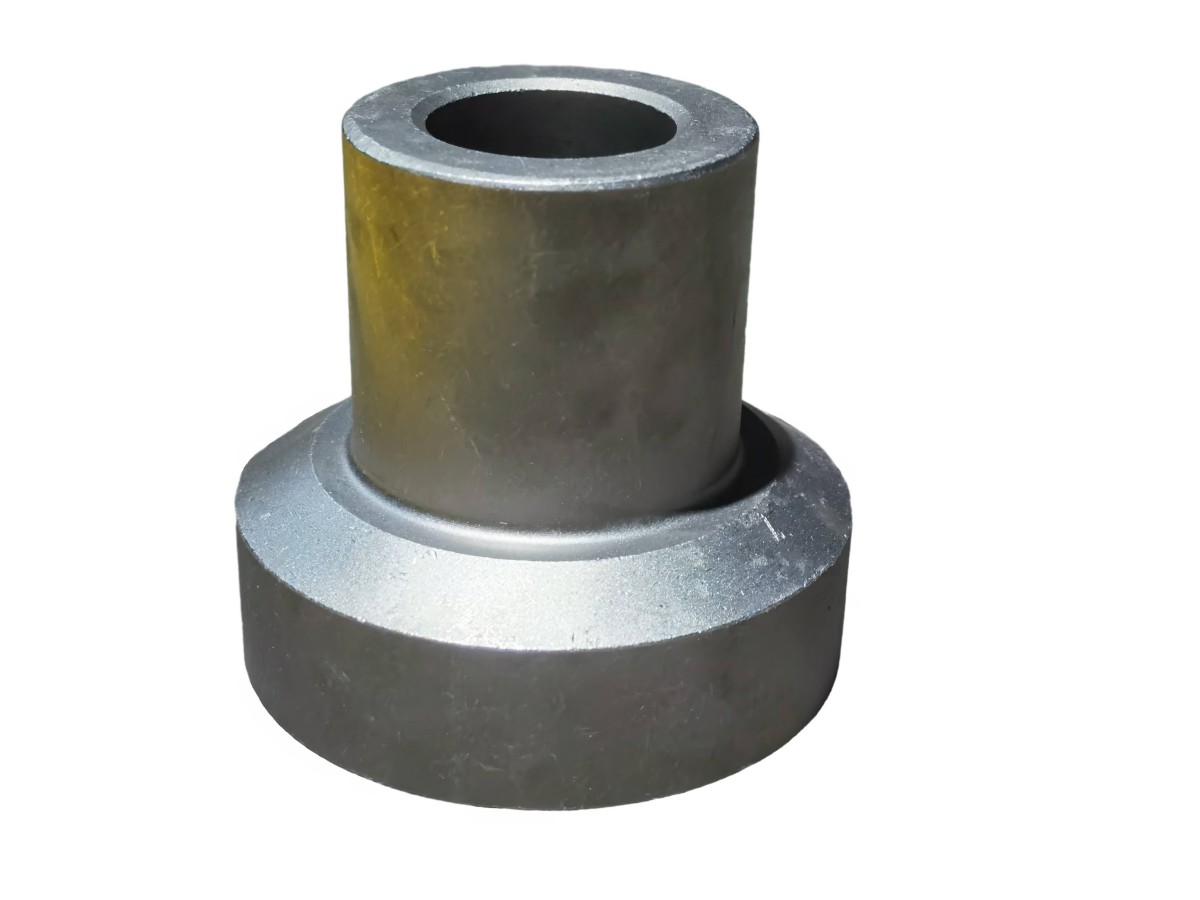

Mine Hexagon Nuts – Heavy-Duty Forged Fasteners

Mine hexagon nuts are vital fastening components widely used in mining, heavy equipment, and construction machinery. Designed for superior strength, wear resistance, and vibration stability, they ensure consistent performance even under demanding loads and challenging conditions. At Weforging, we produce premium hex nuts through hot forging, CNC machining, and precision heat treatment, delivering reliable fastening solutions that meet ISO and ASTM international standards for quality and durability.

Key Features and Performance

Weforging’s forged hexagon nuts are engineered for superior mechanical strength, dimensional precision, and long-term durability. Each nut undergoes a complete hot forging + CNC machining + heat treatment process to ensure tight thread fit, smooth surface finish, and excellent vibration resistance. The forged structure provides improved tensile and shear strength compared to standard machined nuts. With corrosion-resistant coatings and hardness testing, our hex nuts perform reliably under heavy loads, high torque, and harsh operating environments, making them ideal for mining, construction, and heavy equipment applications.

Applications

Mine hexagon nuts are widely applied in:

Mining Equipment – Crushers, conveyors, drilling rigs, and hoisting systems.

Construction Machinery – Excavators, bulldozers, loaders, and tunnel boring machines.

Heavy Trucks and Industrial Vehicles – Axle assemblies, chassis frames, and suspension systems.

Energy and Infrastructure – Offshore platforms, wind power towers, and petrochemical plants requiring secure fastening.

Manufacturing and Quality Assurance

At Weforging, every mine hex nut goes through a complete production cycle:

Hot Forging – Ensures dense internal structure with no porosity.

CNC Machining – Guarantees dimensional accuracy and thread precision.

Heat Treatment – Enhances hardness, toughness, and fatigue life.

Non-Destructive Testing – Includes ultrasonic and magnetic particle inspection.

Final Inspection – CMM measurement and torque testing for 100% compliance.

Contact Us

If your project demands high-strength, precision-forged mine hexagon nuts, Weforging delivers the quality you can trust.

Our engineering team is ready to provide customized solutions and technical consultation.