What is CNC Precision Machining?

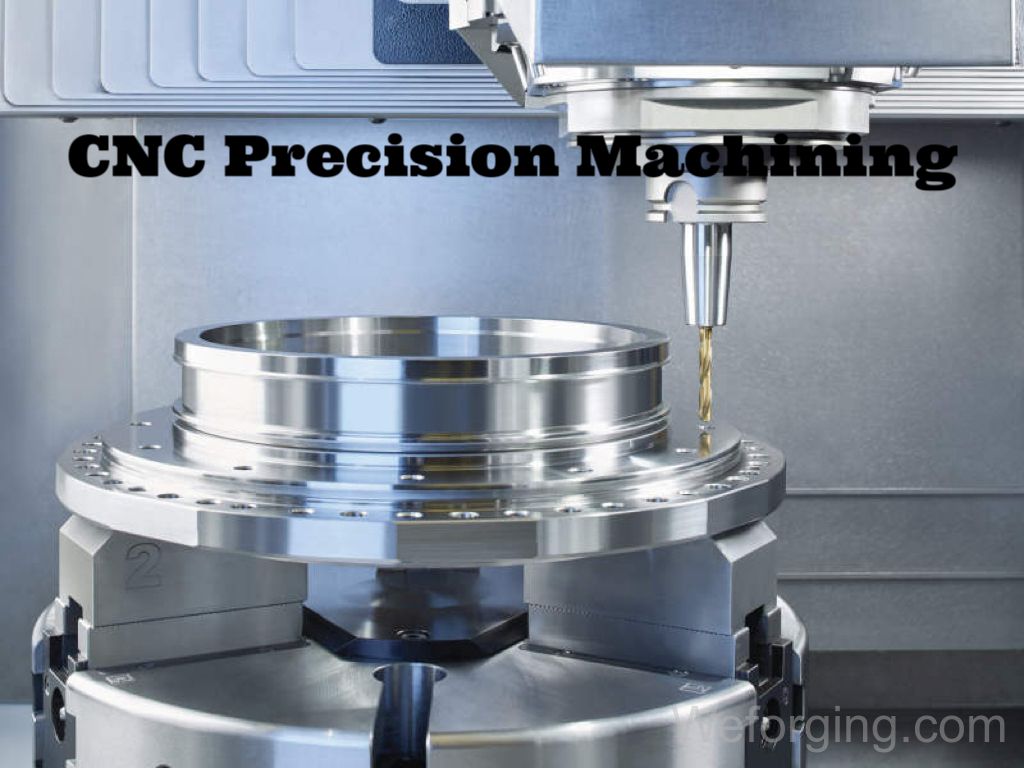

CNC Precision Machining is a vital manufacturing method that uses computer numerical control to achieve exceptional accuracy and efficiency. Unlike manual machining, it ensures consistent quality and enables the production of highly complex CNC precision parts. This process delivers tight CNC machining tolerances, making it indispensable for sectors such as automotive, aerospace, and engineering machinery.

With broad CNC machining applications, it supports everything from gears and shafts to medical components. Beyond accuracy, it also provides key advantages, including higher efficiency, design flexibility, and reduced waste. At Weforging, we combine advanced CNC systems with forging expertise to deliver reliable, cost-effective solutions that meet global standards.

Understanding CNC Precision Machining

CNC precision machining refers to the automated control of machine tools through programmed commands. Unlike manual machining, CNC allows repeated production of parts with high dimensional accuracy. This makes it essential for modern manufacturing, particularly where consistency and complexity are required.

At Weforging, our facilities are equipped with advanced Mazak turning-milling centers, CNC gear hobbing machines, and grinding systems, allowing us to handle projects ranging from small fasteners to large industrial components.

CNC Machining Tolerances Explained

In manufacturing, tolerance defines how much deviation is acceptable in the dimensions of a part. CNC machining tolerances are critical in industries such as aerospace and automotive, where even minor discrepancies can affect safety and performance.

Different sectors demand different levels of accuracy. For example, aerospace parts often require tighter tolerances compared to general hardware. At Weforging, we ensure precision through our CMM inspection systems, ultrasonic and magnetic testing, metallography, and hardness verification.

Industry | Typical Tolerance Range | Features & Applications |

Aerospace | ±0.001 mm – ±0.01 mm | Ultra-high precision for engine parts, structural components, and critical fasteners |

Automotive | ±0.01 mm – ±0.05 mm | Balance between accuracy and cost, used for gears, shafts, nuts, and flanges |

General Hardware / Engineering | ±0.05 mm – ±0.1 mm | Less stringent, suitable for standard fasteners, tools, and structural components |

Applications of CNC Precision Parts

The versatility of CNC machining makes it valuable across industries:

– Automotive – gears, shafts, bolts, and fasteners

– Aerospace – high-strength connectors and structural parts

– Engineering & Construction – flanges, nuts, and large forged components

– Medical Equipment – small yet highly accurate CNC precision parts

– Energy & Heavy Machinery – forged and machined components for wind power, mining, and rail

These CNC machining applications highlight its role in producing reliable, high-performance parts for both everyday use and specialized projects.

Advantages of CNC Precision Machining

The adoption of CNC machining offers several benefits compared to traditional methods:

1. High Accuracy and Consistency – Ideal for producing precision parts with tight tolerances.

2. Efficiency and Speed – Reduced manual intervention improves productivity.

3. Design Flexibility – Ability to machine complex geometries that are impossible with conventional tools.

4. Material Strength – When combined with forging, final products exhibit excellent durability and performance.

These CNC machining advantages make it indispensable for companies that require both mass production and custom solutions.

Why Choose Weforging?

As a global supplier, Weforging provides a unique combination of forging and CNC precision machining under one roof.

– Comprehensive Production Chain – from die forging and ring rolling to machining, gear production, and hydraulic assembly.

– Advanced Equipment – more than 200 precision machines, including Mazak centers and CNC inspection labs.

– Annual Capacity – up to 30,000 tons of forgings across automotive, aerospace, energy, and engineering sectors.

– Project Experience – trusted supplier for large-scale projects such as the Hong Kong–Zhuhai–Macao Bridge and the Guizhou FAST Telescope.

– Customization – flexible services for CNC precision parts ranging from 0.05 kg to 150 kg.

By integrating forging and machining, we ensure products that are not only dimensionally accurate but also structurally stronger.

Conclusion

CNC Precision Machining has transformed modern manufacturing by combining accuracy, efficiency, and flexibility. Its role in producing high-quality CNC precision parts makes it vital across automotive, aerospace, engineering, and medical industries.

At Weforging, we leverage our forging expertise and advanced machining facilities to provide cost-effective, durable, and high-performance components. Whether you need high-volume production or specialized custom solutions, our team ensures parts that meet the highest global standards.

Contact us today to explore our full range of machining and forging solutions.