What Is CNC Turning

CNC turning is one of the core processes in modern precision manufacturing. At Weforging, our CNC turning services combine forging, heat treatment, and CNC machining to produce components with exceptional accuracy and durability. Using advanced turning centers, each operation achieves consistent geometry, fine surface finish, and dimensional stability. This process is widely used for producing high-strength shafts, flanges, and rings. By integrating digital precision with forged metal strength, Weforging ensures every product performs reliably even under demanding mechanical and environmental conditions.

Understanding CNC Turning

CNC turning is a precision machining process in which a rotating workpiece is shaped by controlled cutting tools. Guided by computer programs, the machine removes material gradually to produce accurate diameters, threads, and surfaces. This process is ideal for manufacturing cylindrical and conical parts with tight tolerances and smooth finishes. It is widely applied to steels, aluminum, and other engineering metals. Furthermore, it ensures tight tolerances and dimensional stability. As a result, it provides repeatable quality and reliable performance in modern manufacturing.

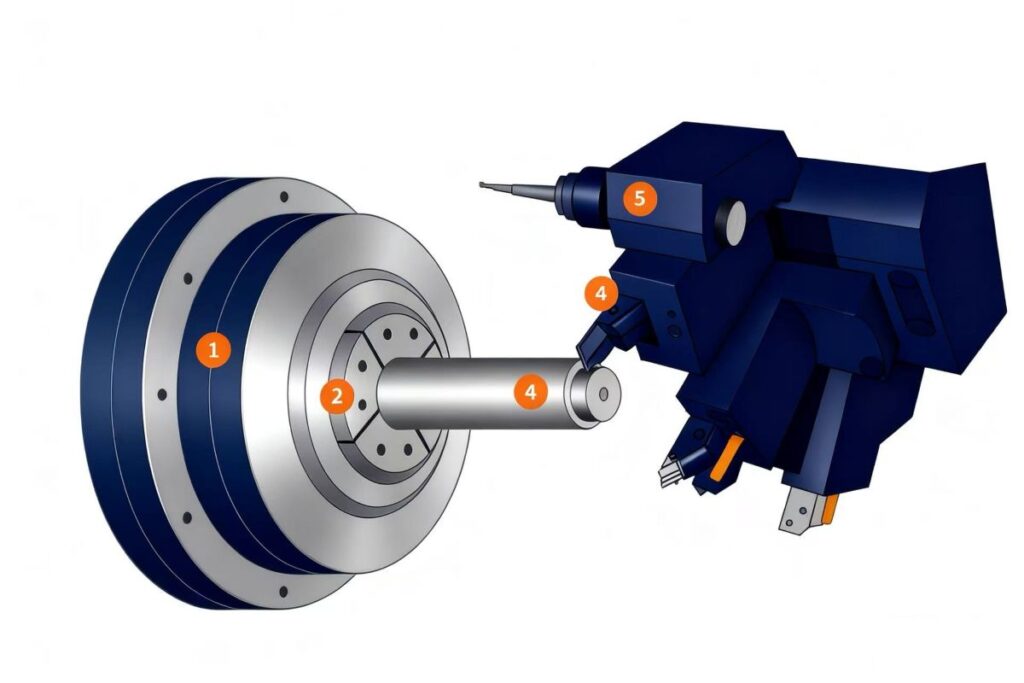

How CNC Turning Works

CNC turning begins with a precision pre-forged blank made from high-quality alloy steel to ensure stable machining and long-term strength. The workpiece is securely clamped in a CNC turning center, where rough and finish cuts are performed with digitally controlled accuracy. This process ensures consistent bore diameters, flat reference surfaces, and accurate outer profiles—essential for high-precision components.

Advanced multi-axis turning systems allow many features, such as tapers, threads, and grooves, to be produced in a single setup. This reduces handling, improves overall efficiency, and keeps tolerances stable throughout production. After machining, the part undergoes polishing and fine finishing to improve surface quality and reduce friction in later assembly. For OEM applications, this integrated workflow offers reliable dimensional control, repeatable performance, and consistent quality across every batch.

Advantages of CNC Turning

1. Micron-Level Precision

CNC turning delivers highly accurate dimensions with digital control, ensuring stable tolerances and consistent geometry across all parts.

2. High Productivity and Process Stability

Automated operation reduces manual intervention, increases machining efficiency, and keeps cycle times stable for both small and large batches.

3. Wide Material Compatibility

The process supports stainless steel, carbon steel, alloy steels, and forged materials while maintaining consistent machining quality.

4. Seamless Integration With Forging and Heat Treatment

CNC turning works effectively with pre-forged blanks and heat-treated components, producing durable, high-strength parts for demanding applications.

5. Reliable Performance Under Harsh Conditions

The precise control of surface finish, concentricity, and dimensional accuracy ensures long-term reliability even under heavy loads and continuous operation.

6. Reduced Setup Time and Improved Flexibility

Multi-axis capability and efficient tooling reduce setup time, supporting both prototype runs and high-volume OEM production.

Common CNC Turned Products

CNC turning covers a wide range of precision metal components used in modern industries. At Weforging, the most common products include:

– Shafts: Drive shafts, gear shafts, and propeller shafts requiring high concentricity and fatigue strength.

– Flanges: Forged or machined sealing flanges used in hydraulic and marine systems.

– Rings: Rolled rings, gear rings, and bearing rings with strict dimensional tolerances.

– Bushings & Sleeves: Bearing sleeves and hydraulic bushings ensuring precise fit and wear resistance.

– Connectors & Fittings: Threaded adapters and hydraulic connectors used for high-pressure sealing.

– Nuts & Fasteners: Drive nuts, flange nuts, and lock nuts for mechanical assemblies.

Each product is forged, heat-treated, and CNC turned under strict process control. This guarantees dimensional accuracy, durability, and consistent performance across all applications.

Industrial Applications

Weforging’s turning parts are used in key global industries. In automotive manufacturing, they serve in drive shafts, couplings, and gear housings requiring precise fit and strength. In the marine sector, propeller shafts and sealing flanges benefit from corrosion resistance and fatigue stability. For energy and hydraulic systems, our machines produce precision bases and connectors ensuring tight sealing and alignment. Each part meets ISO 9001:2015 standards, ensuring consistent quality and reliable operation even under high-stress environments.

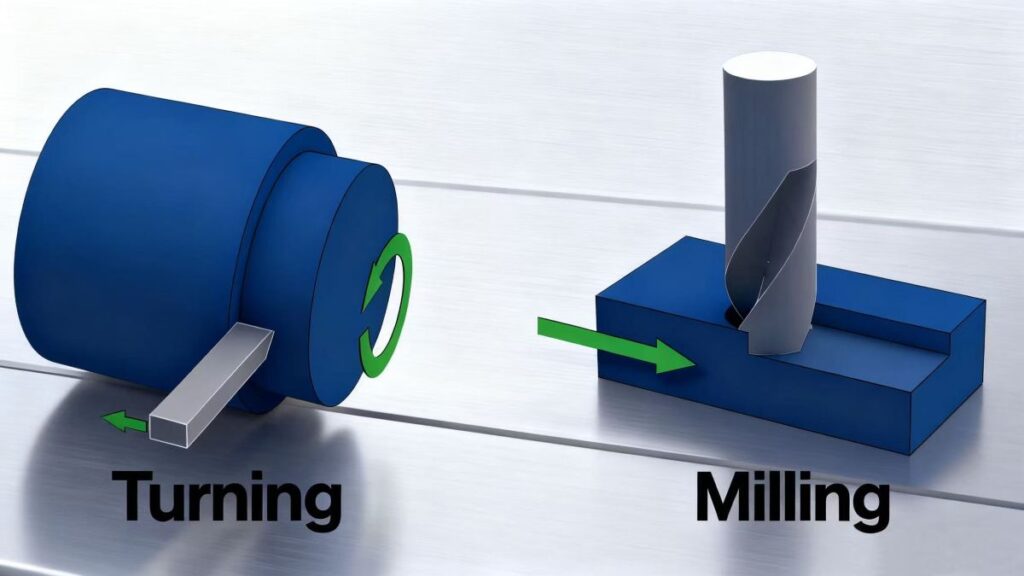

CNC Turning vs CNC Milling

Although both belong to CNC machining, they differ in motion and purpose. CNC turning rotates the workpiece while the tool remains stationary, ideal for circular parts. CNC milling, however, moves the tool across the fixed workpiece to shape planes and contours. Many modern parts combine both techniques—CNC milling and turning—to achieve complex geometries. At Weforging, we use hybrid equipment to manufacture shafts, flanges, and gear hubs, ensuring precision, efficiency, and consistent mechanical performance.

Conclusion

CNC turning stands as the foundation of modern precision CNC machining. At Weforging, we merge forging strength with CNC accuracy to deliver high-quality metal components for global industries. Our integrated approach ensures superior strength, exact tolerances, and dependable performance. Whether for marine systems, automotive drives, or hydraulic assemblies, every product reflects Weforging’s commitment to precision and reliability.

For technical consultation or quotation, please contact Weforging’s engineering team.

F.A.Q.

Weforging’s CNC turning handles alloy steel, carbon steel, stainless steel, and aluminum alloys. Each material is carefully selected and heat-treated to achieve optimal mechanical properties.

We achieve tolerances as tight as ±0.005 mm, ensuring perfect fit for critical components such as flanges, shafts, and valve housings.

The forged parts combines the structural integrity of forging with the precision of modern CNC technology. The forged blanks feature refined grain flow and enhanced toughness, while computer-controlled machining ensures accurate dimensions, smooth surfaces, and tight tolerances. Together, these processes create components with superior mechanical strength, excellent fatigue resistance, and extended service life—making them ideal for critical applications such as shafts, flanges, and gear hubs.