How OEMs Choose Between Forging and Casting for Heavy-Duty Parts

For OEMs manufacturing heavy-duty and load-bearing components, selecting the right production route is a key engineering and procurement decision. In practice, the comparison between forging vs casting goes beyond manufacturing cost and design flexibility, as it directly influences structural strength, fatigue performance, and long-term reliability in demanding operating environments.

Across industries such as mining, construction, and heavy equipment manufacturing, components are routinely exposed to repeated loads, shock forces, and challenging service conditions. By understanding how forging and casting differ in process characteristics and performance outcomes, OEM teams can make informed decisions that balance durability, operational stability, and lifecycle cost.

Forging vs Casting: Manufacturing Process Overview

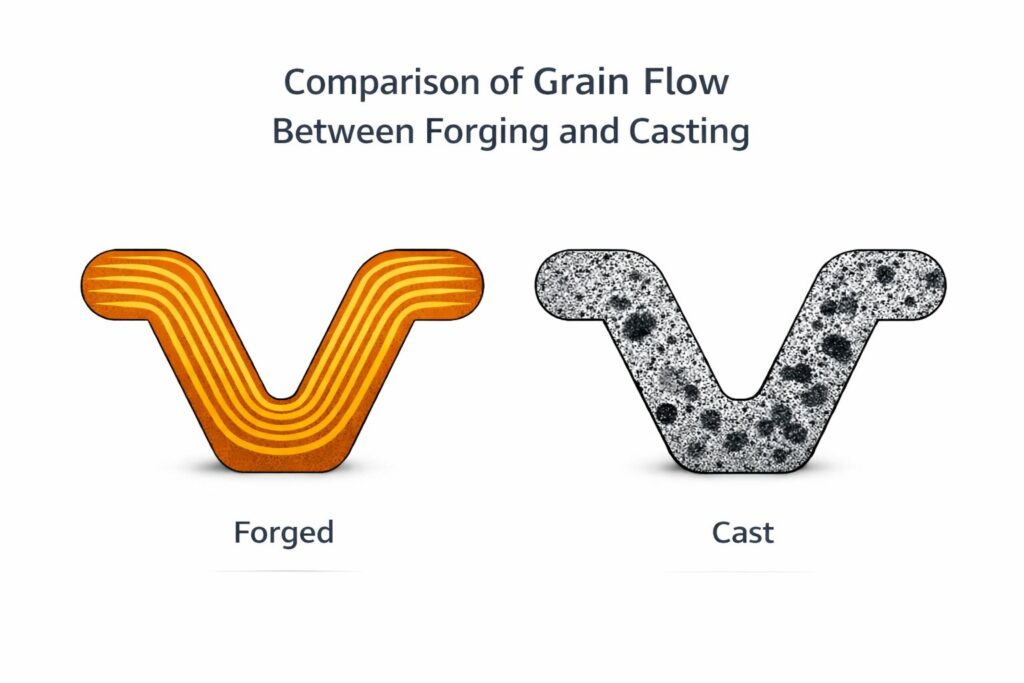

Although forging and casting are both widely used metal forming methods, they differ fundamentally in how material structure is created and controlled.

Forging process characteristics:

- Metal is shaped through controlled plastic deformation under compressive force

- Internal grain flow is refined and aligned with the part geometry

- Material density is increased, supporting higher structural integrity

- Provides stable response to heat treatment and subsequent machining

Casting process characteristics:

- Molten metal is poured into a mold and solidifies into the final shape

- Allows greater freedom for complex geometries and internal cavities

- Solidification may introduce porosity or localized microstructural variation

- Mechanical properties are more sensitive to process and cooling conditions

These process-level differences influence downstream machining, inspection strategy, and performance consistency, making manufacturing route selection a critical decision for heavy-duty components.

Forging vs Casting Strength Comparison for Heavy-Duty Parts

Strength and Performance Comparison Table

Aspect | Forged Components | Cast Components |

Manufacturing principle | Plastic deformation under compressive force | Metal solidification in a mold |

Grain structure | Continuous and directional grain flow | Non-directional, solidified grain structure |

Material density | High density with minimal internal voids | Density depends on solidification control |

Tensile and yield strength | Generally higher and more consistent | Adequate for moderate-load applications |

Fatigue resistance | Excellent resistance under cyclic loading | Lower fatigue performance under repeated stress |

Impact and shock tolerance | Strong resistance to impact and sudden loads | More sensitive to impact conditions |

Heat treatment response | Stable and predictable | More sensitive to process variation |

Suitability for heavy-duty parts | Highly suitable for load-bearing components | Suitable for non-critical or lower-load parts |

This comparison highlights why forged components are commonly selected for heavy-duty and load-bearing applications. Through controlled deformation, forging produces aligned grain flow and higher material density, which directly contributes to the structural advantages of forging, including improved fatigue resistance and impact tolerance.

Cast components can perform effectively in applications with moderate stress levels, but their mechanical properties are more dependent on process stability and inspection control. For OEMs operating in demanding environments, forging offers greater confidence in long-term structural performance.

When to Choose Forging Over Casting

When choosing between forging and casting, tensile strength and yield strength are often decisive factors for heavy-duty applications. Yield strength indicates a component’s ability to resist permanent deformation under sustained load, while tensile strength defines its maximum load-bearing capacity before failure.

Forging is commonly selected when:

Components operate under sustained or cyclic loads where yield strength is critical to maintaining dimensional stability

Higher tensile strength is required to provide sufficient safety margin against peak or impact loads

Long service life and predictable performance are expected in demanding operating conditions

In these situations, the refined grain structure created through forging supports consistent mechanical performance and long-term reliability.

Forging vs Casting for Mining and Construction Equipment

Mining and construction equipment operate in environments characterized by heavy loads, vibration, and abrasive conditions. In these applications, forged components for mining equipment such as ring gears, shafts, pins, and structural connectors are frequently exposed to shock loading and continuous operation.

Forging is often favored due to its superior fatigue performance and resistance to crack initiation, helping OEMs reduce unplanned maintenance and extend service intervals in demanding operating conditions. Casting may still be applied for non-critical or low-stress parts, but load-bearing elements typically benefit from the structural advantages provided by forging.

Quality Control Considerations

Quality control requirements also influence the manufacturing route selection. Forged components benefit from more uniform internal structures, which simplifies non-destructive testing and dimensional control.

Consistent material flow improves traceability across batches and supports stable performance after heat treatment. For OEM procurement teams, this predictability reduces supply risk and improves long-term quality assurance. Casting processes require careful control of solidification and inspection to manage internal defects, making quality outcomes more sensitive to process variation.

Conclusion

Choosing between forging and casting depends on application load, performance expectations, and design priorities. For heavy-duty and load-bearing components, forging is commonly selected for its structural strength, fatigue performance, and long-term stability, while casting is well suited to applications with moderate demands.

OEMs evaluating manufacturing options can benefit from early technical discussion. For projects involving heavy-duty components, our team can review drawings or application requirements to help identify the most appropriate manufacturing route.