Forging Applications in Heavy Machinery

Heavy machinery requires components that can endure high stress and long operation cycles. Forged steel parts provide the strength, density, and fatigue resistance that casting or welding cannot achieve. As a key manufacturing process, heavy machinery forgings ensure stable performance in excavators, cranes, mining trucks, and wind turbine systems.

At Weforging, each forged component is produced through an integrated process combining forging, CNC machining, heat treatment, and inspection. This workflow enhances dimensional accuracy and reliability, supporting demanding industrial operations worldwide.

Why Forgings Are Essential for Heavy Machinery

Heavy machinery operates under extreme loads and vibration. Forged steel provides superior grain flow and structural integrity compared to cast or welded parts, making it ideal for components that must withstand impact and fatigue. Each forged shaft, gear forging, or flange forging delivers uniform strength and dimensional accuracy, ensuring smooth torque transmission and long-term durability.

Typical Forged Components in Heavy Equipment

Forged components are widely used across heavy machinery systems to ensure structural integrity and precise motion transmission. Each category serves a specific mechanical function:

Forged Shafts and Axles – Transfer torque and rotation in excavators, cranes, and trucks. They require high fatigue resistance and dimensional accuracy.

Gear Forgings and Pinions – Enable smooth power transmission in gearboxes and drive systems. Forged gears maintain uniform grain flow and wear resistance.

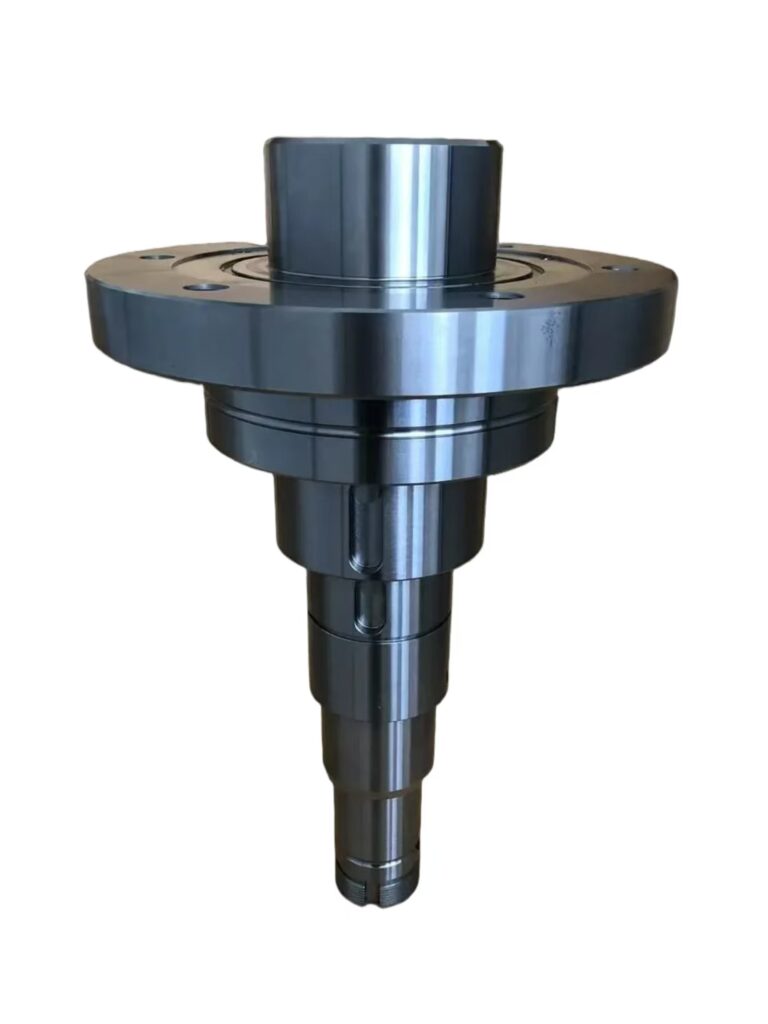

Flange Forgings and Hubs – Provide reliable connections in hydraulic systems and wheel assemblies. They prevent leakage and ensure alignment under heavy load.

Forged Rings and Bearings – Support rotational stability in reducers, wind turbines, and construction machinery. Their dense structure enhances load-bearing capacity.

Alloy Forgings for Couplings and Links – Deliver excellent strength-to-weight ratio and corrosion resistance, suitable for demanding outdoor or mining environments.

Together, these heavy machinery forgings ensure strength, precision, and safety in every industrial operation.

The Forging and CNC Machining Process

Weforging applies advanced hot forging, closed die forging, and ring rolling to form near-net shapes with refined grain structure. Precision CNC machining ensures every tolerance meets design specifications, while heat treatment improves hardness and fatigue life. All forged components undergo ultrasonic (UT) and magnetic particle inspection (MPI) for flawless quality verification.

Quality and Inspection

At Weforging, quality begins with material selection and ends with certified inspection. Every custom forging is tracked from billet to finished part, ensuring full traceability. Using CMM measurement, hardness tests, and dimensional inspection, Weforging guarantees that all forged steel components meet or exceed customer expectations for heavy machinery applications.

Conclusion

Forged components remain the foundation of safety and performance in heavy machinery. From shafts and gears to flanges and hubs, each part plays a critical role in maintaining structural stability and efficiency under demanding conditions. Weforging continues to provide complete solutions integrating forging, CNC machining, and testing, ensuring every forged steel component meets international quality standards.

If your project requires custom heavy machinery forgings, our engineering team can support you from technical evaluation to full-scale production.

📩 Contact Weforging today to discuss your requirements or send your drawings for quotation.