CNC Machining

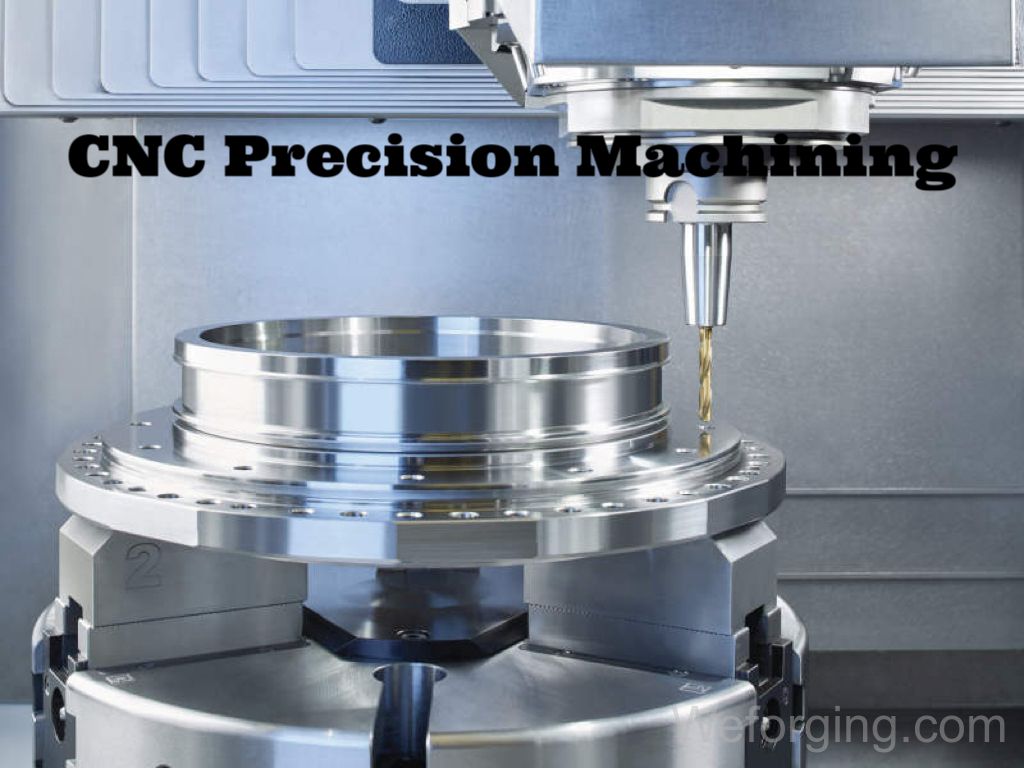

CNC machining is a precision manufacturing process that uses computer-controlled equipment to produce highly accurate and repeatable metal components. As industries increasingly rely on CNC machining services for critical applications, the demand for tighter tolerances and improved surface quality continues to grow. Moreover, when precision CNC machining is applied to forged blanks, the resulting parts achieve exceptional strength and long-term stability, making them ideal for heavy-duty environments.

CNC machining is a computer-controlled manufacturing process used to produce high-precision metal components with consistent accuracy. Using programmed instructions, CNC machines perform turning, milling, drilling, and boring operations to achieve tight tolerances and repeatable results.

In OEM and industrial applications, CNC machining services are widely applied for components requiring precise dimensions and stable batch consistency. CNC machining is often performed on forged blanks, combining structural strength with machining accuracy, making it suitable for shafts, flanges, housings, and other load-bearing parts.

Types of CNC Machining Services

CNC machining is not a single process. Different machining methods are applied based on component geometry, tolerance requirements, and production volume. Weforging provides a full range of CNC machining services to support both forged blanks and machined OEM components.

CNC Turning

CNC turning is used for rotational components such as shafts, rings, and hubs. It delivers precise concentricity and stable dimensional control, making it suitable for power transmission and load-bearing applications.

CNC Milling

CNC milling enables the machining of complex profiles, pockets, and contoured surfaces. It is widely applied to housings, connector blocks, and components requiring multi-face machining.

Multi-Axis CNC Machining (3-Axis / 4-Axis / 5-Axis)

Multi-axis CNC machining allows complex geometries to be completed in fewer setups, improving accuracy and efficiency. This capability is critical for precision OEM parts with tight tolerances and integrated features.

Deep-Hole Boring & Large-Part Machining

For large or thick-walled components, deep-hole boring and large-part machining are applied to achieve controlled straightness, alignment, and internal surface quality.

Our CNC Machining Capabilities

Weforging provides in-house CNC machining services for forged and machined OEM components. Our capabilities support tight tolerances, complex geometries, and stable batch consistency.

Key capabilities include:

CNC turning for shafts and rings (up to Ø800 mm)

CNC milling for complex profiles and surfaces

3-axis, 4-axis, and 5-axis machining centers

Deep-hole boring and precision end finishing

Surface roughness up to Ra 0.4 μm

Dimensional tolerance up to ±0.01 mm

Materials: carbon steel, alloy steel, stainless steel, aluminum

Integrated tool monitoring and on-machine measurement ensure consistent machining accuracy across every production batch.

CNC Machined Parts We Produce

Weforging manufactures a wide range of CNC machined components designed to withstand heavy loads while maintaining tight dimensional tolerances.

For many load-bearing and precision-critical parts, CNC machining is performed on forged blanks, combining structural strength with high machining accuracy.

This integrated forging and machining approach helps our customers achieve reliable long-term performance, even in demanding industrial and OEM applications.

We commonly produce:

Shafts and drive shafts for power transmission systems

Flanges and connector blocks for piping and mechanical assemblies

Housings, bearing seats, and covers requiring precise alignment

Rings, hubs, and spindles with controlled concentricity

Custom OEM precision components based on drawings or specifications

CNC Machining Advantages

High dimensional accuracy

CNC machining supports tight tolerances and repeatable precision, making it suitable for components with strict dimensional and assembly requirements.Consistent quality across batches

Automated machining processes and in-process measurement systems help maintain stable quality from prototype to serial production.Capability for complex geometries

Multi-axis CNC machining enables the production of complex profiles, contoured surfaces, and integrated features within a single setup.Improved surface finish

Controlled cutting parameters allow surface roughness to meet functional and assembly needs without excessive secondary processing.Wide material compatibility

CNC machining is suitable for carbon steel, alloy steel, stainless steel, aluminum, and other engineering materials.Efficient integration with forged blanks

Machining on forged components combines structural strength with precision, supporting load-bearing and long-term performance requirements.Flexible production volumes

CNC machining supports both small-batch customization and stable repeat production for OEM programs.

Why Choose Weforging for CNC Machining

Weforging provides integrated CNC machining services designed for OEM and industrial applications where dimensional accuracy, batch consistency, and delivery reliability are critical.

Key reasons customers choose Weforging include:

Integrated forging and CNC machining

Forging and machining are coordinated in-house, allowing controlled machining allowances and reduced production lead times.Capability for large and complex components

Our machining capacity supports large diameters, extended lengths, and complex geometries commonly required in heavy-duty equipment.Stable dimensional control and inspection

Machined components are verified through in-process measurement, dimensional inspection, and quality control procedures.Material and standards alignment

Machining processes are aligned with ASTM, DIN, and EN standards for carbon steel, alloy steel, and stainless steel materials.OEM and export-oriented experience

We support international OEM projects requiring consistent quality, documentation, and repeatable performance across production batches.

Conclusion

Choosing the right CNC machining partner is essential for ensuring long-term performance, stable tolerances, and reliable delivery. As industrial components continue to become more complex, OEM buyers increasingly require suppliers who can provide precision CNC machining along with strong engineering support. At Weforging, our integrated forging and machining capabilities allow us to deliver stronger parts, faster production times, and consistent quality across every batch.

If you are looking for CNC machining services, custom CNC machined parts, or engineering support for your project, we are ready to help.

Send us your drawings or technical requirements for a fast and professional quotation.