Premium Forged Valve Bodies | High-Precision

At Weforging, we specialize in manufacturing high-precision valve bodies through integrated forging, CNC machining, heat treatment, and quality testing. Each valve body is produced using premium carbon steel, alloy steel, or stainless steel, ensuring exceptional strength, sealing reliability, and dimensional accuracy.

Our forged and machined valve bodies are widely used in hydraulic systems, oil & gas valves, transmission units, and construction machinery, meeting the high-performance requirements of global OEM clients.

Product Overview

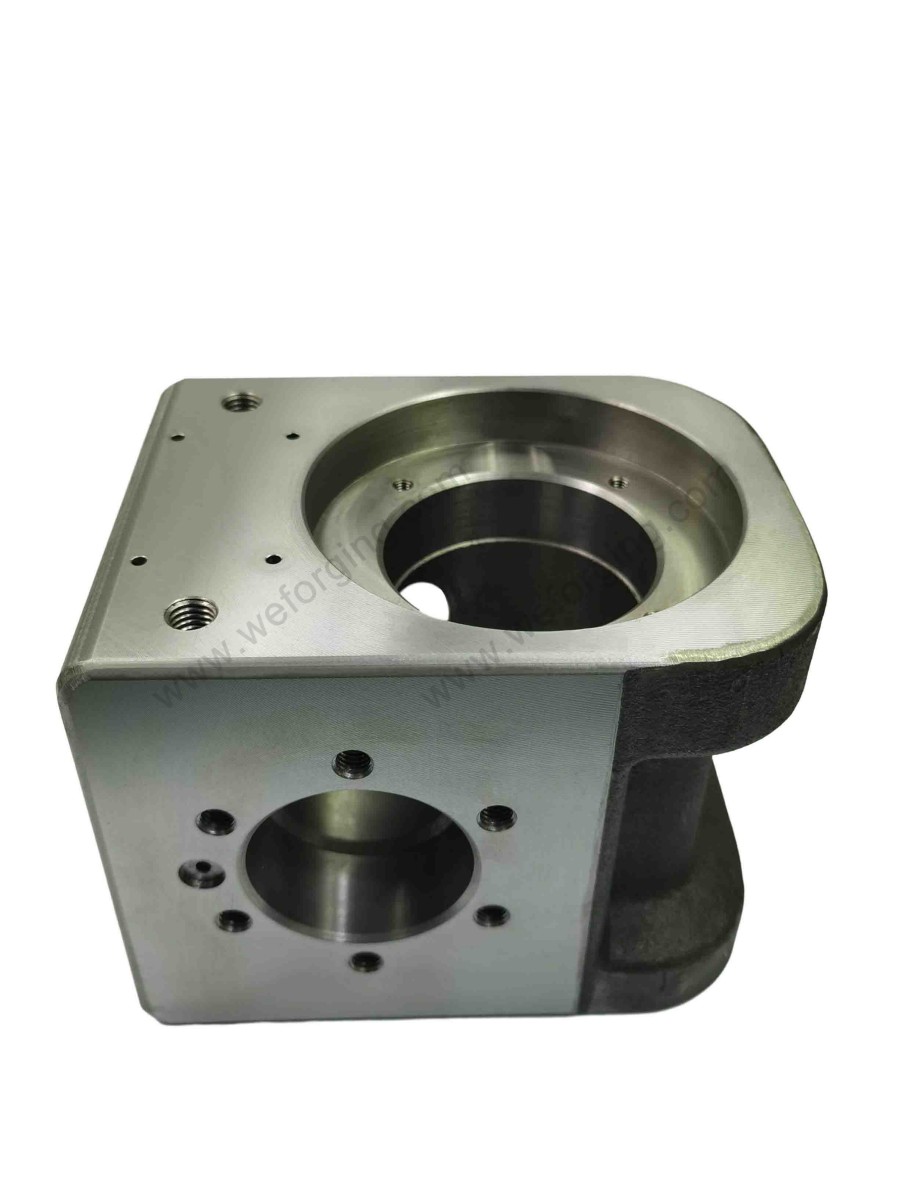

The valve body is a critical component that regulates fluid flow and pressure in hydraulic and transmission systems. Weforging’s valve bodies are produced through closed-die forging to achieve dense internal grain structure and high mechanical integrity.

Compared with casting or welded structures, forged valve bodies provide superior fatigue strength, dimensional stability, and corrosion resistance—ideal for heavy-duty industrial applications where consistent pressure control is required.

Materials and Specifications

Each valve body is forged from high-quality materials such as carbon steel, 42CrMo alloy steel, or stainless steel (SS304/316).These materials are selected for their combination of tensile strength, wear resistance, and compatibility with hydraulic oils.After forging, the parts undergo heat treatment, CNC turning, milling, and drilling, resulting in smooth internal flow channels and tight dimensional tolerances.Standard surface finishes include anodizing, phosphating, or anti-corrosion coating depending on client requirements.

Key Advantages of Forged Valve Bodies

High Strength and Density — Forged structure eliminates porosity and enhances fatigue resistance.

Dimensional Accuracy — CNC machining ensures perfect sealing and smooth fluid transitions.

Corrosion Resistance — Alloy and stainless steels maintain stability under temperature and pressure changes.

Material Efficiency — Forging achieves near-net shapes, reducing waste and machining time.

Custom Engineering Support — Tailored valve body design and DFM optimization based on 2D/3D drawings.

Applications

Hydraulic Systems — Precision control of fluid flow and pressure regulation.

Automotive Transmissions — Transmission valve bodies for reliable shifting and oil channel balance.

Oil & Gas Equipment — Pressure-resistant valve housings for extreme environments.

Construction & Mining Machinery — High-strength valve housings for excavators, cranes, and presses.

Industrial Automation — Custom valve assemblies for production and forming systems.

Contact

If your project requires a forged or CNC machined valve body, our engineering team can assist with design optimization, material selection, and process feasibility.

Upload your 2D/3D drawings (PDF, DWG, or STEP), and our engineers will provide a technical review and quotation within 24 hours.