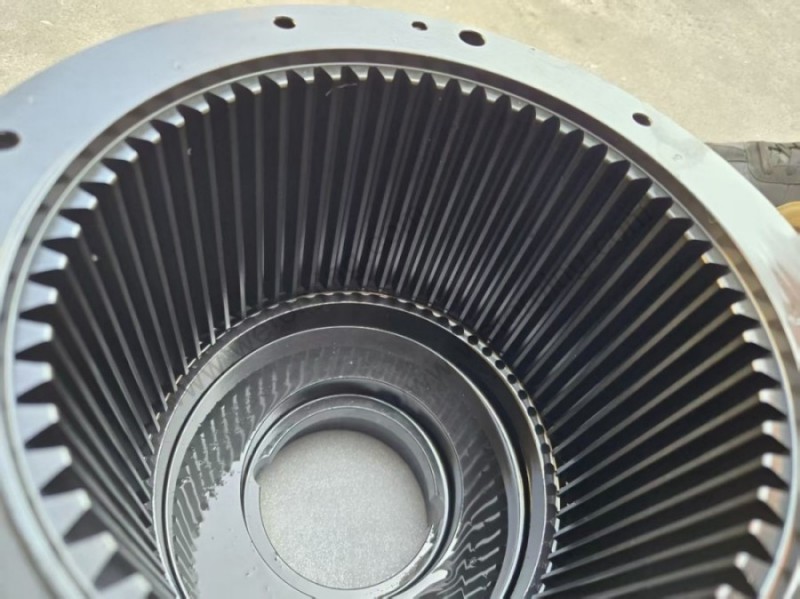

Precision Inner Ring Forgings for Industrial Applications

At Weforging, we specialize in precision inner ring forgings designed to meet the most demanding industrial requirements. Our high-quality inner rings are forged from premium alloy steels and undergo advanced CNC machining to ensure optimal dimensional accuracy and performance. With a focus on strength, durability, and reliability, our inner ring forgings serve a wide range of applications across industries such as automotive, aerospace, heavy machinery, and renewable energy.

Inner Ring Forging Process

The forging of inner rings involves multiple precision-controlled stages to achieve structural integrity and dimensional accuracy.

Billet Selection and Heating — High-quality alloy or carbon steel billets are cut to the required size and heated uniformly to 1050–1250°C to ensure ideal plasticity and refined grain flow.

Upsetting and Preforming — The heated billet is upset and roughly shaped to achieve the target cross-section and prepare for ring formation.

Piercing (Punching) — A central hole is punched to create a donut-shaped blank. This allows accurate metal flow during the rolling stage.

Ring Rolling — Using advanced ring-rolling mills, the blank is expanded radially and axially to achieve precise wall thickness and diameter control, aligning the grain structure circumferentially.

Heat Treatment — Processes such as normalizing, quenching, and tempering enhance mechanical strength, fatigue resistance, and dimensional stability.

CNC Machining & Inspection — Precision machining (turning, grinding, drilling) ensures tolerance accuracy up to ±0.01 mm. Ultrasonic, hardness, and dimensional inspections guarantee quality and traceability.

This process produces inner rings with excellent concentricity, load-bearing capacity, and fatigue strength.

Key Features of Precision Inner Ring Forgings

Superior Strength and Durability

Our forged inner rings are made from high-strength materials for excellent performance in demanding conditions. The forging process refines the grain flow, improving strength and fatigue resistance—ideal for high-load and rotating parts.

Tight Dimensional Tolerances

Advanced CNC machining ensures precise dimensions and smooth surfaces. This accuracy provides a perfect fit, enhances system efficiency, and reduces extra processing.

Versatility and Customization

Weforging offers flexible solutions for custom sizes and materials. Our engineers design optimized inner rings to ensure reliable performance and assembly compatibility.

Corrosion Resistance

Made from alloy and corrosion-resistant steels, our inner rings perform reliably in harsh environments, maintaining stability under moisture, chemicals, and temperature changes.

Applications of Precision Inner Ring Forgings

Automotive: Used in transmission systems, wheel hubs, and drive shafts, our precision inner rings ensure smooth operation and long service life.

Aerospace: Critical components in landing gear and engine systems, where precision and reliability are crucial for safety and performance.

Industrial Machinery: Our inner rings support heavy machinery in high-load environments, including construction, mining, and material handling equipment.

Energy: Precision inner rings are essential for wind turbines and hydraulic systems, where efficiency and durability are paramount.

Why Choose Our Inner Ring Forgings?

At Weforging, we take pride in our integrated manufacturing system that combines precision forging and advanced CNC machining.Each component is produced to meet the highest standards of quality and reliability.With efficient lead times and optimized production costs, we provide practical, high-value solutions for OEM clients worldwide.We focus on consistency, precision, and customer satisfaction makes Weforging a trusted global partner.

Contact us today to learn how our precision inner ring forgings can meet your specific application needs or request a quote for your next project.