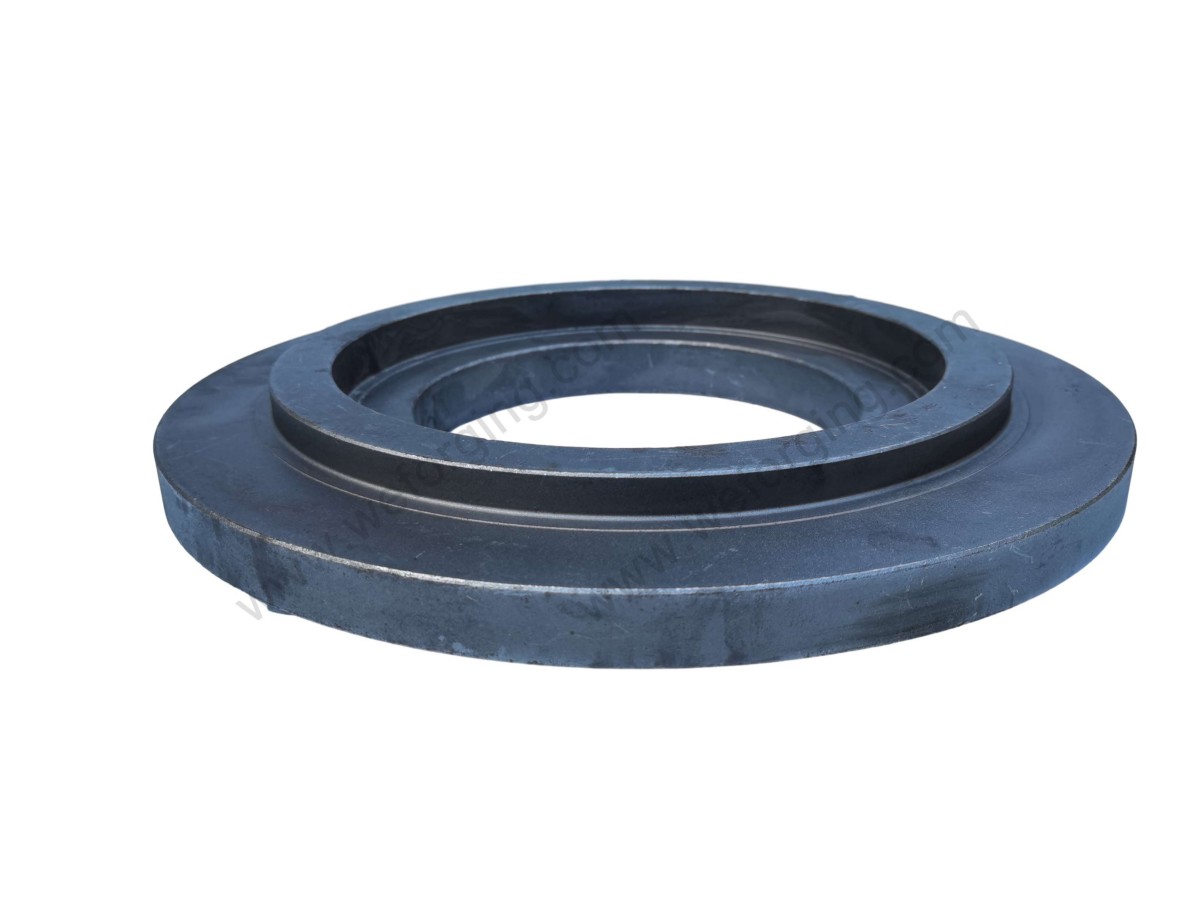

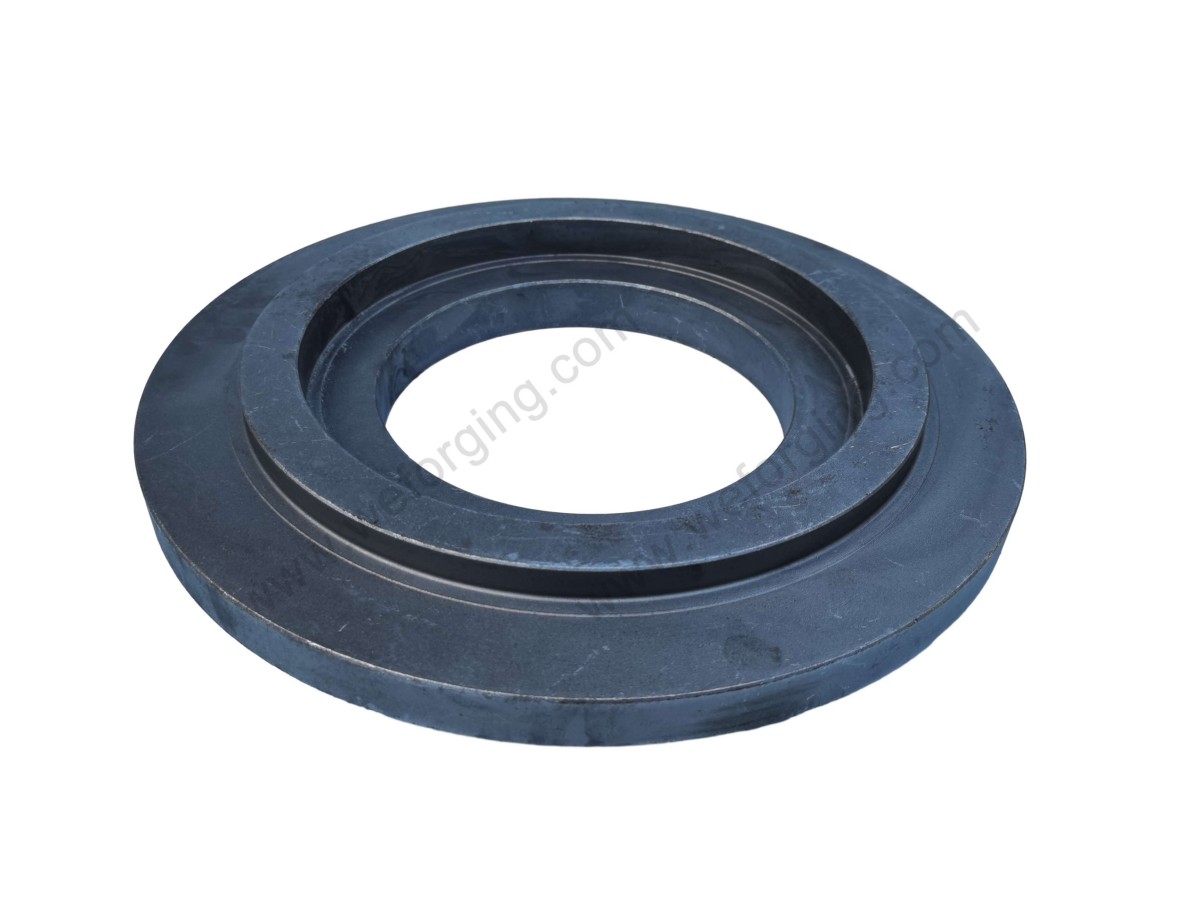

Slewing Bearing Rings – Forged & CNC Machined Ring Components

A slewing bearing ring is a precision-engineered rotating component widely used in excavators, cranes, wind energy yaw systems, and industrial turntables. Compared with cast or welded parts, a forged slewing ring blank offers superior strength, longer service life, and higher load-bearing capability under continuous heavy-duty operation.

Weforging provides both forging blanks and fully machined rings with optimized raceway geometry, ensuring stable rotation and reliable structural performance.

Manufacturing Process & Technical Performance

Our slewing bearing rings are produced through a controlled forging process that aligns metal grain flow and removes porosity. This improves strength and resistance to cyclic loading.

After forging, rings undergo CNC machining for the raceway, bolt holes, and sealing surfaces.

Key performance features include:

Consistent raceway geometry

Stable hardness after heat treatment

Accurate roundness and flatness for smooth rotation

Core Advantages

Weforging’s slewing bearing rings offer strong stability under load and long service life.

Main advantages include:

High fatigue resistance due to forged structure

Precise machining for consistent rolling performance

Optional raceway hardening for enhanced wear resistance

These benefits make the rings suitable for harsh working environments and long operation cycles.

Application of Slewing Bearing Rings

Our rings are widely used in equipment that requires controlled rotation and high load capacity:

Construction machinery such as excavators and cranes

Wind turbine yaw and pitch systems

Industrial turntables and welding positioners

Mining and bulk handling machinery

Their durability and load performance make them ideal for heavy-duty operations.

Technical Specifications

| Parameter | Value |

|---|---|

| Diameter Range | 500–3000+ mm |

| Materials | 42CrMo, 50Mn, 42CrNiMo |

| Heat Treatment | Normalizing / Q&T / Raceway hardening |

| Hardness | Core HRC 28–36, Raceway HRC 55–62 |

| NDT | Ultrasonic + Magnetic Particle Testing |

OEM Custom Capability

We offer flexible production options based on customer needs. Rings can be supplied as:

Forged blanks

Semi-finished rings

Fully machined bearing rings

Customization includes bolt-hole layouts, raceway geometry, sealing surfaces, and surface treatments. Full quality documentation is available for OEM audits.

Why Choose Weforging

Weforging has over 40 years of forging and CNC machining experience. Our integrated workflow—forging, heat treatment, machining, and testing—ensures stability and repeatable quality.

We support small batches, prototypes, and mass production with export-grade packaging and reliable delivery.