Ring Rolling vs Open Die Forging: Which Is Better for Large Rings?

Large metal rings are critical components in heavy-duty industrial systems such as construction machinery, energy equipment, and power transmission assemblies. Operating under high loads and cyclic stresses, their long-term performance and reliability depend heavily on the selected manufacturing process. Among available methods, ring rolling and open die forging are two widely used but fundamentally different approaches to producing large rings. Each process affects grain flow orientation, material efficiency, dimensional control, and application suitability. This article compares ring rolling and open die forging from an engineering and procurement perspective, with a focus on selecting the most appropriate process for large diameter industrial rings.

What Is Ring Rolling Forging?

Ring rolling forging is a specialized forming process used to produce seamless rolled rings. The process begins with a pre-forged ring blank that is heated and radially expanded between a driven roll and a mandrel. During rolling, the ring rotates as its diameter increases while wall thickness is reduced in a controlled manner.

As a result, this process forms a continuous circumferential grain flow that follows the ring geometry. Compared with other forging methods, rolled ring forging provides higher material efficiency and improved mechanical performance along the primary load path, making ring rolling well suited for large diameter rings with relatively uniform cross-sections in high-performance industrial applications.

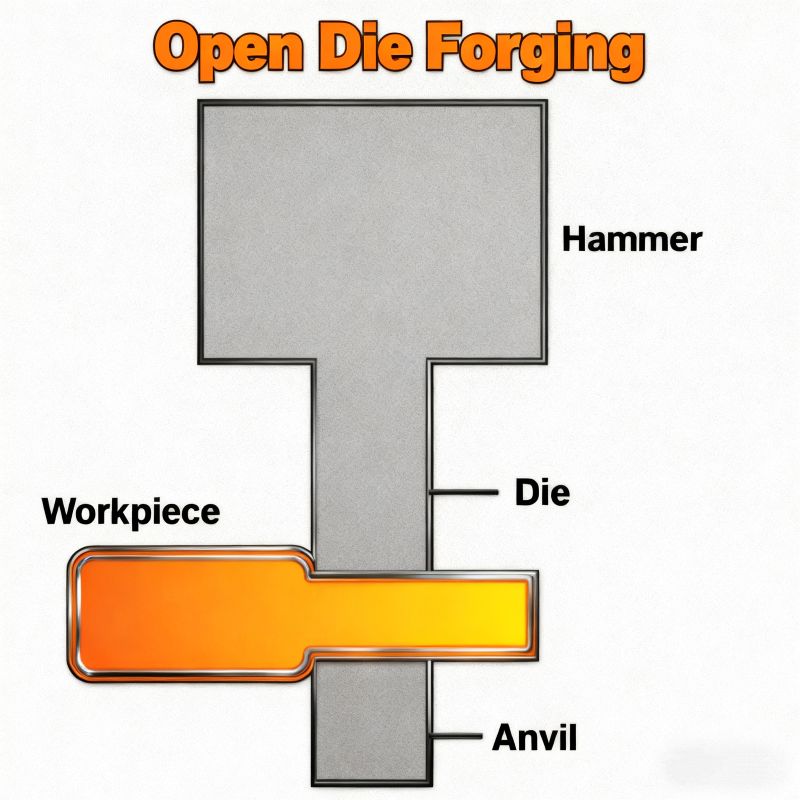

What Is Open Die Forging for Rings?

Open die forging is a traditional forging process in which heated metal is shaped between flat or contoured dies without fully enclosing the workpiece. For ring production, a solid billet is first forged, then punched or expanded to create a ring geometry.

Unlike rolling-based processes, open die forging relies on repeated compressive deformation rather than circumferential expansion. While this process refines the material structure, the resulting grain flow does not form a continuous circumferential pattern and is therefore more suitable for applications with complex geometries, significant wall thickness variation, or relatively low production volumes.

Key Characteristics of Seamless Rolled Rings

Seamless rolled rings produced through ring rolling offer structural and dimensional characteristics that support reliable performance in heavy-duty industrial applications. A key feature is continuous circumferential grain flow that follows the ring geometry, enhancing resistance to fatigue and cyclic loading.

In addition, seamless rolled rings provide uniform wall thickness and consistent diameter control, contributing to stable stress distribution and predictable mechanical behavior in service. From a manufacturing perspective, ring rolling enables efficient material utilization and reduced machining allowance, supporting cost-effective production of large diameter rings.

Ring Rolling vs Open Die Forging: Key Differences

When comparing ring rolling and open die forging, several technical factors are particularly relevant for large diameter rings.

Comparison Factor | Ring Rolling | Open Die Forging |

Grain Flow Orientation | Continuous circumferential grain flow, improving fatigue resistance and uniform load distribution | Discontinuous grain patterns, generally suitable for static loads but less optimal for cyclic stress |

Material Utilization | High material efficiency due to near-net shape expansion during rolling | Lower efficiency, often requiring larger machining allowance and higher material loss |

Dimensional Control | Precise control of diameter and wall thickness, especially for seamless rolled rings with uniform sections | Wider dimensional tolerances, requiring additional machining for accuracy |

Suitability for Large Diameter Rings | Well suited for large diameter rings with consistent cross-sections and performance-critical applications | More suitable for variable cross-sections or lower-volume, less dimension-sensitive applications |

Which Process Is Better for Large Rings?

For large diameter ring manufacturing, the choice between ring rolling and open die forging depends on application requirements rather than a universal “best” solution.

However, in applications where consistent grain flow, dimensional stability, and long-term fatigue performance are critical, ring rolling has become the dominant and often irreplaceable process. By aligning the material structure with service loads, seamless rolled rings provide predictable performance under rotating and load-bearing conditions. Open die forging remains suitable for complex geometries or limited production volumes, but its applicability becomes increasingly constrained as performance demands increase.

Typical Industrial Applications of Rolled Ring Forgings

Rolled ring forgings are widely used in heavy industrial applications due to their structural consistency and efficient material utilization. Typical applications include:

Gear blanks for power transmission – supporting stable torque transfer and reliable fatigue performance

Slewing bearing rings for construction equipment – enabling smooth and dependable rotation under combined loads

Flange rings for pressure connections – providing secure interfaces and structural support

Large bearing rings for rotating systems – ensuring dimensional consistency and smooth operation

These components benefit from uniform grain flow and controlled geometry, supporting reliable performance in long-term service applications.

Conclusion

Both ring rolling and open die forging are used in the production of large industrial rings, with the appropriate process determined by ring size, geometry, and performance requirements. For applications where large diameter rings, consistent grain flow, and dimensional stability are critical, ring rolling is commonly selected.

If your project involves ring rolling or large ring applications, our team is available for technical discussion and process evaluation.