When to Choose Die Forging

In modern metal forming, die forging stands out as one of the most efficient methods to produce strong, precise, and repeatable components.By compressing heated metal within dies, it enhances grain flow and mechanical integrity while ensuring dimensional accuracy.Engineers evaluate factors such as part geometry, production volume, and performance needs to decide between open die forging and closed die forging.Understanding these conditions helps determine when die forging offers the best balance of strength, cost, and precision for industrial and OEM forging applications.

What Is Die Forging?

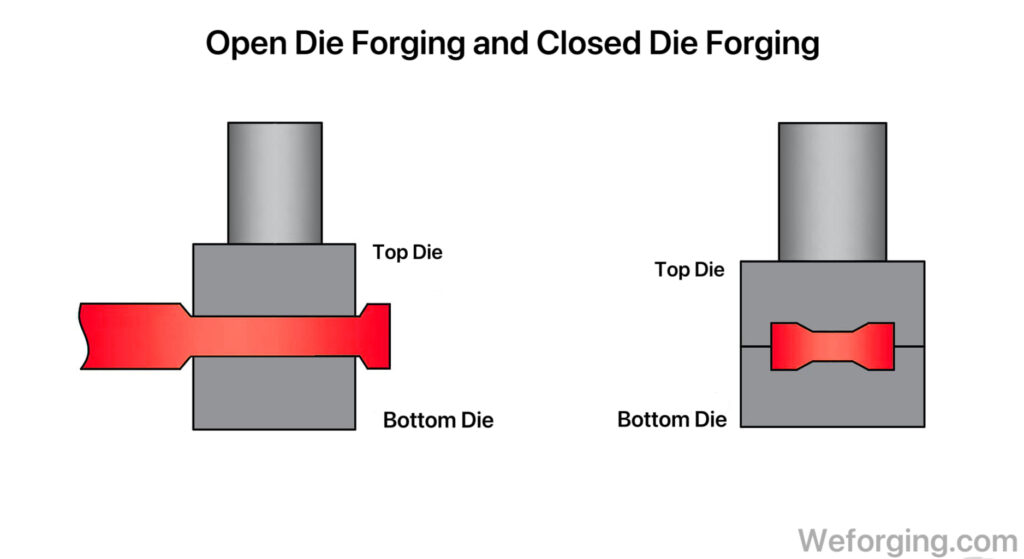

Die forging is a process in which metal is deformed between two dies that shape it into the desired geometry. During the closed die forging process, preheated billets are compressed within matched dies to form precise contours, while excess material (flash) is later trimmed. In contrast, open die forging involves shaping larger parts between flat or simple dies without full enclosure.

This controlled deformation aligns the metal grain structure with the part’s geometry.It increasing strength and fatigue resistance — a key advantage over casting or machining.

When to Choose Die Forging

Die forging is most suitable when parts require high strength, precise geometry, and consistent quality across medium to high production volumes.

Choose die forging when:

– Complex geometry demands repeatable precision (e.g., flanges, gears, and couplings).

– High strength or fatigue resistance is required for load-bearing parts.

– Material efficiency is a concern — forging minimizes waste compared with machining.

– OEM standardization requires consistent tolerances and mechanical reliability.

Open Die Forging vs Closed Die Forging

Both open and closed die forging share the same metallurgical benefits but differ in scale and precision.

Aspect | Open Die Forging | Closed Die Forging |

Forming Method | Metal is deformed freely between flat or simple dies | Metal is shaped within fully enclosed dies under high pressure |

Part Size | Suitable for large components such as shafts and rings | Ideal for small and medium precision parts |

Tolerance | Moderate precision | High precision and dimensional repeatability |

Tooling Cost | Lower tooling cost | Higher tooling cost but reusable for mass production |

Production Volume | Low to medium | Medium to high |

Material Utilization | Flexible but less efficient | High utilization and minimal waste |

Surface Finish | Requires additional machining | Near-net shape, minimal machining required |

Typical Applications | Gears, fittings, connecting rods |

Leran more about open die forging vs closed die forging.

Applications of Die Forging

The applications of die forging span across heavy-duty and precision industries where reliability and strength are essential.

- Automotive Industry:

Die forging is used for drive shafts, connecting rods, differential gears, and steering components.

These forged parts provide high torque capacity and fatigue resistance in commercial vehicles, trucks, and construction machinery. - Energy and Wind Power:

Forged flanges, hubs, and coupling rings are vital in wind turbines, pipelines, and pressure systems.

They maintain sealing integrity and load-bearing stability under variable or high-pressure conditions. - Construction and Heavy Equipment:

Hydraulic pistons, arms, and joints produced by die forging offer strength and impact resistance.

They are commonly used in excavators, loaders, and hydraulic presses operating under repeated loads. - Marine and Mining:

Forged shafts, anchor rings, and propeller hubs deliver excellent corrosion resistance and long-term durability.

These components are ideal for offshore equipment and abrasive mining environments.

Each forged component maintains refined grain flow, structural consistency, and dimensional integrity.These properties are critical for systems exposed to high stress and safety requirements.

Advantages Over Other Metal Forming Techniques

Compared with other metal forming techniques such as casting, stamping, or machining, die forging delivers superior strength, precision, and long-term reliability.The controlled deformation of heated metal refines the internal grain structure and improves material density.As a result, tensile and impact strength increase, while porosity and internal defects are greatly reduced.This refined microstructure gives forged parts superior structural integrity and mechanical consistency under demanding conditions.

Forged components maintain uniform properties throughout the cross-section.This ensures excellent fatigue resistance and dimensional stability in demanding environments.Die forging also provides a smoother surface finish and requires less machining allowance.These advantages improve production efficiency and reduce material waste.

Conclusion

Die forging offers the best balance of strength, precision, and production efficiency for modern industrial manufacturing.By selecting the right forging method — open or closed — engineers can achieve superior mechanical performance, consistent geometry, and reduced material waste.For OEM and engineering projects requiring tailored solutions, custom forging provides the flexibility to meet specific material, dimension, and load requirements.

For custom forging inquiries or project consultations, please contact our engineering team to discuss your requirements and receive a professional quotation.

F.A.Q.

The main advantage of die forging over casting lies in its superior mechanical strength and structural integrity.During the forging process, heated metal flows along the shape of the part, creating a continuous and dense grain structure.This alignment minimizes porosity and eliminates weak points that are often present in castings.

As a result, forged components provide higher reliability under cyclic loads, impacts, and high-pressure conditions.They are especially suitable for critical parts such as gears, shafts, and flanges used in demanding industrial systems.

Closed die forging is preferred when components require high dimensional precision, complex geometries, and consistent quality.It produces near-net-shape parts with minimal machining and excellent repeatability — suitable for mass production of precision components.

In contrast, open die forging is more suitable for large structural parts such as shafts and rings, where directional grain flow and toughness are prioritized.

Yes. Modern die forging supports full OEM customization, including material selection, die design, CNC machining, and non-destructive testing.

Manufacturers like Weforging provide custom forged parts for automotive, energy, marine, and heavy equipment sectors.

This ensures each component meets precise mechanical standards, dimensional tolerances, and international quality certifications.