What Is CNC Milling

CNC milling is a precise and versatile manufacturing method used to create complex metal parts with consistent accuracy. Using computer-controlled toolpaths, a CNC milling machine removes material from forged or solid blocks to achieve tight tolerances and clean surfaces. At Weforging, every component runs through an integrated forging + CNC machining + testing workflow. Moreover, our ISO-certified process combines advanced equipment with disciplined quality validation, ensuring dependable results for automotive, energy, and industrial applications.

What Is CNC Milling and How It Works

CNC milling is a subtractive process in which rotating cutters remove material while the workpiece is fixtured. The heart of the method is digital control: a CAM program converts a 3D CAD model into G-code, which orchestrates spindle speed, feed rate, tool engagement, and multi-axis motion. Consequently, complex contours—such as pockets, ribs, and free-form surfaces—are produced with repeatable accuracy. Furthermore, closed-loop feedback on modern machines stabilizes positioning, while tool compensation maintains geometry as inserts wear. This synergy of software, fixturing, and metrology enables Weforging to mill forged blanks into dimensionally stable, high-strength parts.

The CNC Milling Process Explained

The CNC milling process transforms a 3D design into a precise finished part through several digital stages.

- Design: Each component starts with a 3D CAD model, created under DFM (Design for Manufacturing) principles. Proper wall thickness, hole spacing, and tolerance settings ensure smooth machining and accurate inspection later.

- CAM Programming: The model is then processed in CAM (Computer-Aided Manufacturing) software, which generates G-code. This code defines tool paths, cutting speeds, and coolant control. Moreover, simulation within CAM helps verify tool motion, reducing setup time and improving machining reliability.

- Machining: The CNC milling machine follows the G-code automatically. The workpiece—often a forged blank—is fixed securely as rotating tools remove material layer by layer. Roughing, semi-finishing, and finishing passes gradually form the final geometry while maintaining dimensional stability.

- Inspection: After machining, the part undergoes CMM measurement and surface roughness checks. In addition, in-process probes confirm critical dimensions, ensuring that each product meets design accuracy and quality standards.

Through this coordinated workflow, Weforging ensures every forged and CNC-milled part delivers consistent performance, high strength, and excellent surface finish.

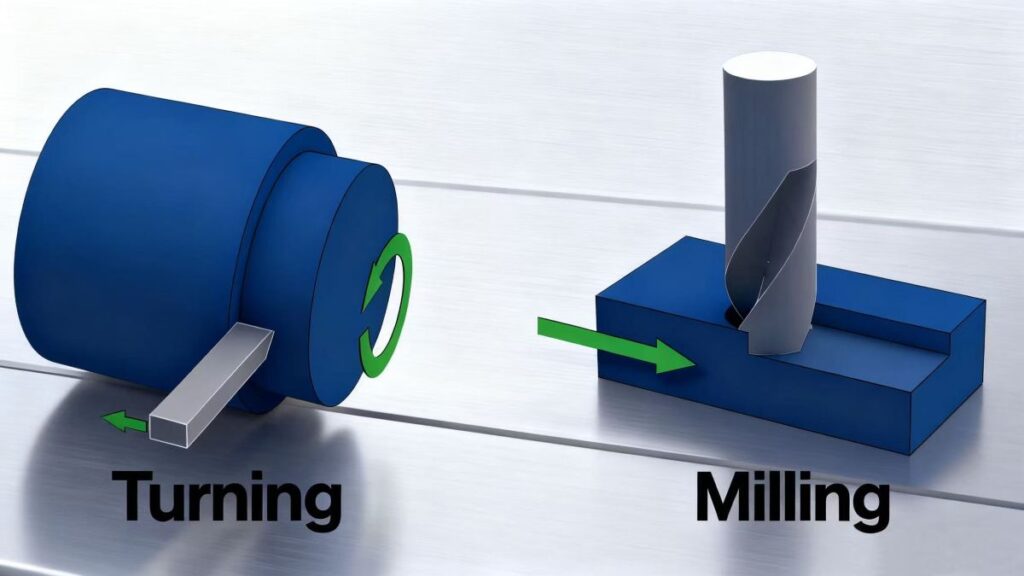

CNC Milling vs CNC Turning

Both CNC milling and CNC turning deliver precision, yet their kinematics guide different choices. Milling excels when parts require prismatic features, intersecting surfaces, or multi-axis contours; pocketed housings, valve blocks, and flange faces are typical examples. Turning shines when the geometry is primarily rotational—shafts, bushings, or tapered seats—where concentricity and roundness dominate. Moreover, hybrid routings often win: turn the datum diameters first for concentricity, then mill the functional faces and features. In addition, cost drivers differ. Milling time depends on toolpath complexity and tool changes, while turning time correlates with diameter, length, and material removal along the axis. By selecting the right mix, Weforging optimizes tolerance stack-ups, surface integrity, and overall throughput.

Advantages of CNC Milling

For forged parts, CNC milling offers more than geometry freedom. Because forged blanks arrive with directional grain flow, milling can preserve load paths while achieving tight tolerances on functional faces. Furthermore, multi-axis strategies reduce re-clamping, thereby maintaining datum integrity and improving cumulative accuracy. Surface integrity also benefits: tailored cutting parameters, edge prep, and coolant delivery limit tensile surface effects and support uniform finishes before heat treatment. As a result, downstream processes—such as carburizing, grinding, or honing—start from a stable geometry, which shortens validation loops and enhances consistency across batches.

Applications of CNC Milling in Industry

CNC milling plays a vital role in multiple industrial sectors, where precision and repeatability are essential.

- Automotive Systems:

CNC milling defines transmission housings, differential covers, and bearing seat faces, improving gear alignment, sealing, and NVH performance in drivetrains. - Hydraulic Equipment:

Accurate pocket depths and flat sealing surfaces on valve blocks ensure smooth hydraulic flow and long-term sealing reliability. - Wind and Energy Systems:

Balanced gear hubs and bolt circles are critical for torque transmission. Multi-axis milling completes these features in a single setup, ensuring alignment and efficiency. - Construction Machinery:

High-load flanges, joint interfaces, and gear carriers require strong surface contact and repeatable geometry for durability under heavy torque. - Marine and Industrial Machinery:

Components use corrosion-resistant materials and uniform finishes. Controlled milling and verified inspection deliver stability in harsh marine and industrial environments.

Together, these applications demonstrate how Weforging’s CNC milling ensures strength, dimensional accuracy, and performance across diverse global industries.

CNC Milling Machines & Equipment at Weforging

Weforging operates vertical, horizontal, and 5-axis CNC mills with high-speed spindles, through-spindle coolant, and digital monitoring. Furthermore, automatic tool changers and probing systems shorten cycles while sustaining accuracy. Large-envelope machines manage sizeable forged blanks for gears, shafts, and flange gears; compact centers handle high-mix parts with agile setups. In addition, our process library—covering tool grades, coatings, entry strategies, and exit paths—standardizes best practices across materials, which supports predictable surface quality and repeatable tolerances.

Quality Control and Testing

Quality is embedded in the flow. First, incoming forged blanks are referenced and traced; then, in-process probing validates datums before each critical pass. Moreover, CMM verification confirms dimensions and positional tolerances, while roughness checks benchmark finishing strategies. Heat-treated parts receive hardness and case-depth confirmation to align with functional requirements. In addition, ultrasonic and magnetic particle methods assess internal consistency and surface integrity. Therefore, every lot aligns with ISO, DIN, and AGMA expectations, demonstrating Weforging’s commitment to precision and dependable performance.

Inquiry and Customization

Weforging provides custom CNC milling for forged components—covering design consultation, CAM optimization, prototype validation, and series production. Moreover, our team aligns material choice, tolerance budgets, and inspection plans with your performance targets.

Contact Weforging to accelerate your next program with integrated forging and precision milling.

F.A.Q.

Typical milled features hold ±0.01–0.03 mm depending on geometry, material, and setup. Moreover, critical fits can be tightened with finishing strategies such as reaming or grinding.

Choose CNC turning for primarily rotational geometries; select CNC milling for prismatic shapes or multi-axis contours. In addition, hybrid routings—turn then mill—often deliver the best balance of concentricity and feature accuracy.

We regularly machine alloy steels (e.g., 42CrMo, 4140), carbon steels, stainless steels, and aluminum. Furthermore, tool selection and coolant strategy are tailored to each material for surface integrity and throughput.