How OEMs Select the Right Forging Process for Heavy-Duty Applications

For OEMs working with heavy-duty applications, forging process selection is a critical decision made early in project planning. Components used in construction machinery, mining equipment, energy systems, and industrial drives often operate under high loads and long service cycles, making the choice of forging method closely tied to performance, manufacturability, and delivery consistency.

Instead of viewing forging methods in isolation, OEM engineering and procurement teams evaluate how different forging processes align with component geometry, material requirements, production volume, and downstream machining. This article outlines how OEMs approach forging process selection for heavy-duty applications, providing practical guidance to support informed manufacturing and sourcing decisions.

What Is Forging Process Selection in Heavy-Duty Manufacturing

Forging process selection refers to the evaluation and choice of a forging method that best supports component function, manufacturability, and production planning. In heavy-duty manufacturing, this decision is closely linked to part size, load conditions, and expected service life.

OEMs typically define forging routes early in the project lifecycle, as this choice influences material flow, machining allowances, inspection methods, and supplier coordination. Selecting a suitable forging process helps establish a stable manufacturing foundation for subsequent operations.

Key Factors Affecting Forging Process Selection

- Component size and geometry

Large dimensions, section thickness, and shape complexity influence the suitable forging process. - Load conditions and service environment

Expected load levels and operating conditions define the performance requirements for the forging route. - Production volume and project scope

Project-based or moderate production volumes often favor more flexible forging processes. - Material grade and applicable standards

Compliance with ASTM, EN/DIN, ISO, or customer-specific standards shapes feasible forging options. - Downstream machining and inspection needs

The forging process should integrate smoothly with machining, heat treatment, and inspection planning.

Common Forging Processes for Heavy-Duty Applications

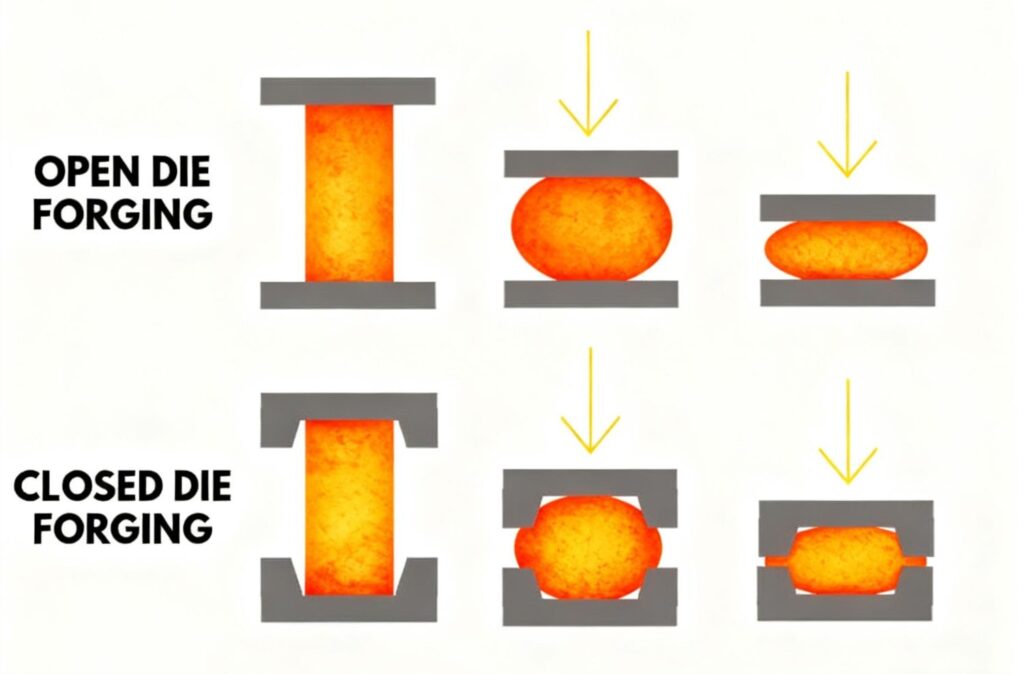

Several forging processes are commonly applied in heavy-duty manufacturing. Open die forging is widely used for large or non-standard components where dimensional flexibility is important. Closed die forging is typically selected for smaller parts produced in higher volumes with defined shapes. Ring rolling is often applied to large ring-shaped components, supporting efficient material utilization and stable geometry.

OEMs assess these processes based on component requirements and production planning rather than treating them as interchangeable options.

Open Die vs Closed Die Forging: How OEMs Compare Options

When comparing open die and closed die forging, OEMs focus on how each process supports component requirements, production planning, and sourcing strategy.

Open die forging is commonly used for large or non-standard components where dimensional flexibility is important. It supports a wide size range and allows geometry to be refined during early project stages, making it suitable for project-based manufacturing and low to medium production volumes.

Closed die forging is typically applied to components with defined geometries and stable specifications. Once tooling is established, it offers high repeatability and efficient production, which aligns well with higher-volume programs and standardized designs.

By evaluating size range, tooling approach, and production scale, OEMs can select the forging process that best supports manufacturing consistency and long-term sourcing goals.

How to Choose a Forging Process Based on Application Needs

Forging process selection is often guided by application-driven priorities. Heavy-duty components that require reliable load support, coordinated manufacturing, and clear material definition are commonly matched with forging routes that support these goals.

OEMs also consider how forging integrates with machining and inspection, as coordinated manufacturing helps maintain consistency across production stages. Early alignment between engineering and procurement teams supports efficient decision-making.

Forging Process Selection and Manufacturing Coordination

Manufacturing coordination plays a key role in forging process selection for heavy-duty applications. The selected forging route influences how machining operations, inspection steps, and delivery schedules are planned and aligned throughout the project lifecycle.

OEMs typically prioritize forging processes that support smooth coordination across forging, machining, heat treatment, and quality control. When manufacturing stages are well aligned, production planning becomes more predictable, technical communication is simplified, and overall project execution remains stable.

Testing and Inspection Capabilities Required for Forging

- Mechanical testing capability

Tensile strength and yield strength testing are used to verify that forged components meet specified mechanical performance requirements. - Metallurgical examination

Metallographic analysis supports confirmation of material structure after forging and heat treatment, helping ensure consistency with material specifications. - Non-destructive testing (NDT)

Ultrasonic testing (UT) and magnetic particle inspection (MT) are commonly applied to evaluate internal and surface integrity without affecting the component. - Standards compliance and traceability

Testing and inspection activities are typically conducted in alignment with applicable standards, with results documented to support traceability across the manufacturing process.

How OEMs Evaluate Forging Suppliers During Process Selection

Supplier evaluation is an integral part of forging process selection. OEMs typically assess suppliers based on a few core considerations:

Forging capabilities and process coverage, matching the required forging method and component size range

Quality systems and inspection capability, aligned with OEM standards and project requirements

Production capacity and delivery planning, supporting consistent execution across project timelines

Technical communication and project coordination, enabling smooth alignment during design and manufacturing

Manufacturing integration, with the ability to coordinate forging, machining, and inspection within a unified process

Conclusion

Forging process selection for heavy-duty applications is a system-level decision that balances application needs, manufacturing coordination, and sourcing strategy. By evaluating key factors early and aligning engineering with procurement, OEMs can establish a manufacturing route that supports consistent performance and efficient project execution.

If you are evaluating forging options for a specific project, our team is available to provide technical input and manufacturing guidance. You are welcome to contact us for a free consultation, with responses typically provided within 24 hours.