Hot Forging Services for High-Strength Steel Components

Hot forging is a precision metal-forming process that shapes heated metals under controlled pressure. At Weforging, we integrate forging, CNC machining, and testing to produce forged steel and alloy steel forging components with high strength, toughness, and dimensional stability. The hot forging process refines the grain structure, enhances mechanical performance, and ensures consistent quality across large production batches. It is widely applied in automotive, energy, and heavy equipment industries, where reliability and precision are critical.

Types of Hot Forging Processes

Hot forging is not a single manufacturing method. Depending on component size, geometry, and production volume, different hot forging processes are applied to achieve optimal material flow and dimensional control.

Open Die Forging

Open die forging is used for large, custom steel components where flexibility in shape and size is required. Without fully enclosed dies, material can be progressively forged to achieve refined grain flow and high structural integrity.

This process is commonly applied to shafts, rings, blocks, and heavy-duty components produced in low to medium volumes.

👉 Learn more about open die forging capabilities.

Closed Die Forging

Closed die forging utilizes shaped dies to form components with defined geometries and tighter repeatability. It is suitable for medium to high production volumes where consistent shape and near-net dimensions are required, such as gear blanks, couplings, and precision connectors.

👉 Learn more about closed die forging capabilities.

Rolled Ring Forging

Rolled ring forging is a specialized hot forging process for large ring-shaped components. By expanding the ring diameter while reducing wall thickness, this method improves material utilization and grain flow continuity. It is widely used for flanges, bearing rings, and slewing ring blanks.

👉 Explore our rolled ring forging solutions.

Hot Forging Process

The hot forging process begins by heating alloy or carbon steel billets to between 1,050°C and 1,250°C. Once the billet reaches the optimal forging temperature, it is transferred to a hot forging press or hammer machine where it is shaped under high pressure. Controlled deformation allows the metal to flow uniformly, refining the microstructure and eliminating internal defects.

After forging, processes such as trimming, shot blasting, and CNC machining are performed to achieve precise dimensions. Finally, heat treatments like quenching, tempering, or normalizing further enhance the part’s strength and toughness.

Materials Used in Hot Forging

Weforging manufactures hot forged steel components using a wide range of materials including:

Alloy Steels (42CrMo, 35CrMo, 4140, 4340, 8620H) — For high-load parts like shafts, gears, and flanges.

Carbon Steels (40Cr, 20CrMnTiH) — Excellent machinability and toughness for general engineering.

Stainless Steels (304L, 316) — Corrosion-resistant for marine and energy systems.

Aluminum and Copper Alloys — Lightweight and conductive for aerospace and electrical components.

All materials are tested and certified under ISO, DIN, and AGMA standards, ensuring stable performance and long service life.

Typical Hot Forged Components

Hot forging is commonly selected for components that require high load capacity, fatigue resistance, and long-term reliability. At Weforging, hot forged parts are often supplied as forged blanks or combined with CNC machining for precise dimensional control.

Typical hot forged components include:

Shafts and drive shafts for power transmission systems

Forged rings and bearing rings for rotating assemblies

Flanges and pressure-rated connectors

Gear blanks and hubs for heavy-duty gearboxes

Large structural blocks for machining-intensive applications

These components are widely used in OEM equipment where material strength and internal structural integrity are critical to performance.

Hot Forging Temperature Chart

| Material | Temperature Range | Heating Method |

|---|---|---|

| Carbon Steel (C45, 1045) | 1100–1250 °C | Induction / Furnace |

| Alloy Steel (42CrMo / 4140) | 1050–1200 °C | Furnace → Soaking |

| Stainless Steel (304 / 316L) | 1180–1250 °C | Gas furnace / High-temp |

| Aluminum Alloys | 400–480 °C | Short-cycle heating |

| Copper / Brass | 650–900 °C | Induction preferred |

| Titanium Alloys | 900–950 °C | Controlled-atmosphere |

Hot forging is typically performed above the recrystallization temperature of metal, allowing deformation without work hardening.

Advantages of Hot Forging

Hot forging offers a unique balance of strength, efficiency, and precision that few manufacturing methods can match.

By shaping metals at elevated temperatures, the process promotes optimal plastic flow and internal structural refinement — ensuring exceptional performance in demanding applications.

Refined Grain Structure:

During hot deformation, the grain flow naturally aligns with the direction of applied stress. This structural refinement minimizes internal defects and significantly improves fatigue resistance, especially in load-bearing components.Efficient Material Utilization:

The near-net-shape forming capability of hot forging reduces material waste and machining time, resulting in better yield and cost efficiency across large-scale production.Dimensional Stability and Repeatability:

Advanced forging presses and precision-controlled heating systems allow consistent deformation and uniform tolerances, ensuring that every forged component meets strict dimensional requirements.Versatile Material Compatibility:

Hot forging is suitable for a wide range of materials—from carbon and alloy steels to stainless steels—providing flexibility for diverse mechanical and environmental demands.Enhanced Mechanical Properties:

Follow-up heat treatments such as quenching and tempering strengthen hardness, toughness, and wear resistance, enabling forged parts to deliver long-term durability even under cyclic or high-stress conditions.

Why Choose Weforging for Hot Forging

Weforging provides integrated hot forging services for OEM and industrial applications requiring strength, dimensional control, and process reliability.

Key reasons OEM customers choose Weforging include:

Integrated forging and CNC machining

In-house coordination enables controlled machining allowances, shorter lead times, and consistent dimensional results.Large and custom forging capability

Supports large cross-sections, extended lengths, and non-standard geometries for heavy-duty applications.Dimensional control and inspection

Defined tolerances verified through in-process measurement, dimensional inspection, and material testing.Material and standards alignment

Carbon, alloy, and stainless steels aligned with ASTM, DIN, and EN standards.Export-oriented OEM experience

Proven support for international projects with consistent quality and documentation.

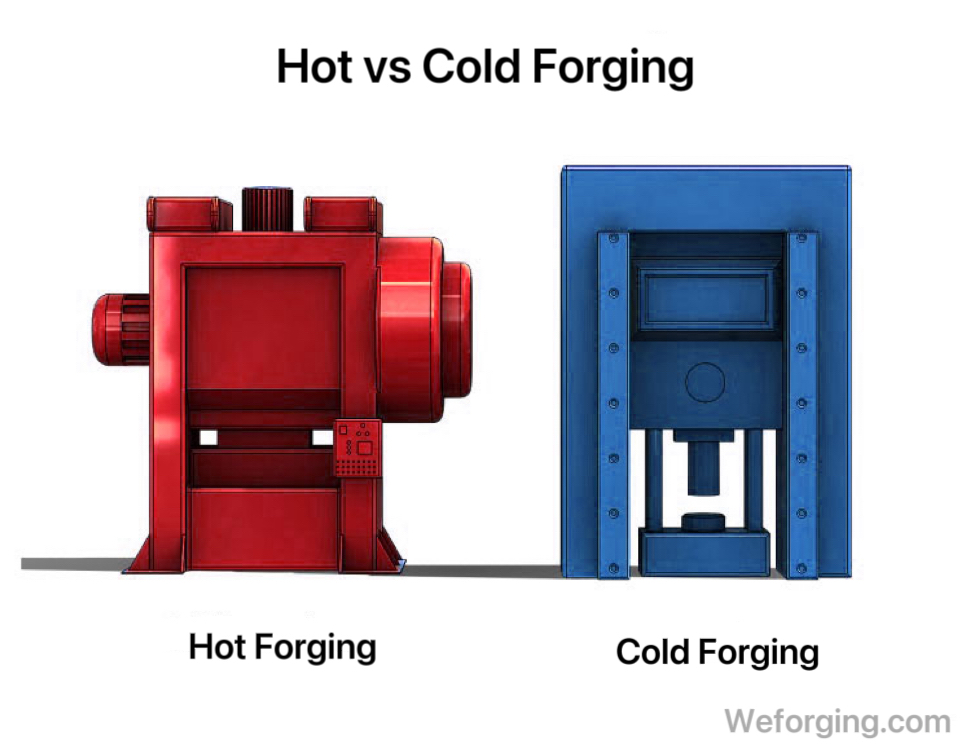

| Aspect | Hot Forging | Cold Forging |

|---|---|---|

| Working Temperature | 1,050°C – 1,250°C (high-temperature plastic zone) | Room temperature or ≤150°C (ambient forming) |

| Material Flow | Excellent metal flow; refined grain structure | Limited deformation; restricted flow |

| Strength Characteristics | High strength and good ductility after heat treatment | Higher initial hardness but lower ductility |

| Surface Finish | Oxidized surface; requires post-machining | Smooth surface; minimal machining required |

| Dimensional Accuracy | Moderate precision; suitable for larger or complex parts | High precision; ideal for small fasteners |

| Typical Components | Shafts, flanges, gears, couplings | Bolts, nuts, pins, fasteners |

| Energy Consumption | Higher (requires heating) | Lower (formed at room temperature) |

Applications & Industries

Hot forging is widely applied across multiple high-performance industries where strength, reliability, and precision are essential:

Automotive Industry:

Hot forging is used to manufacture forged steel components such as axles, connecting rods, crankshafts, and gear blanks.

These parts provide excellent fatigue strength and ensure long-lasting drivetrain performance in vehicles.Energy & Oil & Gas Industry:

The process produces flanges, couplings, and valve components that operate reliably under extreme temperature and pressure.

Hot forged parts maintain superior toughness, sealing integrity, and corrosion resistance for energy and pipeline systems.Agricultural Machinery Industry:

In agricultural equipment,it is applied to produce gear hubs, transmission shafts, and connecting joints that withstand continuous vibration, shock, and heavy loading.

These alloy steel forgings enhance the durability and operational stability of tractors, harvesters, and soil machinery.Heavy Machinery & Construction Equipment:

Hot forging is ideal for shafts, wheels, and bearing housings that require high load capacity and impact durability.

It ensures stable operation and extended service life for construction, mining, and industrial equipment.

Conclusion & Contact

Hot forging remains one of the most efficient and reliable methods for manufacturing high-strength, precision-engineered parts.

At Weforging, our integrated system of forging, CNC machining, and testing ensures consistent quality and global delivery standards.

📞 Looking for a reliable forging company?

Click the inquiry button below to get a real-time quote or upload your drawings.

Our engineering team will provide technical guidance and a tailored quotation for your project.