What is Rolled Ring Forging?

Rolled ring forging, often called ring forging, is a precise metal-forming process used to produce seamless, high-strength rings. The process begins by piercing a solid round billet and shaping it through high-temperature rolling and forging to achieve uniform density and excellent mechanical properties. Compared with other manufacturing methods, rolled ring forgings provide outstanding strength, toughness, and fatigue resistance, making them ideal for aerospace, energy, automotive, and heavy machinery applications where performance and reliability are essential.

Rolled Ring Forging Process Steps

At weforging manufacturing, the rolled ring forging process follows a standardized, high-precision workflow to ensure the final product meets strict industry standards.

1. Raw Material Cutting (Billet Shearing)

This process involves choosing the appropriate metal material and size specification, usually mainly in the form of bars. Material: Carbon steel, alloy steel SAE8620H, etc., stainless steel or non-ferrous metals, etc. The billets are then cut to the required length using billet shearing, ensuring accurate weight and volume for forging.

2. Electric Furnace Heating

After cutting, the billets are heated in an electric furnace to a forging temperature, usually between 1,100°C to 1,250°C (2,000°F to 2,300°F). Controlled heat treatment forging ensures uniform temperature distribution, which is essential for achieving superior grain flow and material strength.

3. Pre-Forming (Upsetting and Rough Forging)

After the billet reaches the required forging temperature, it undergoes upsetting to increase its cross-sectional area and refine its internal structure. This process ensures uniform material distribution and eliminates voids or segregation. The billet is then rough-forged to achieve the approximate ring shape, improving metal flow for the subsequent piercing stage.

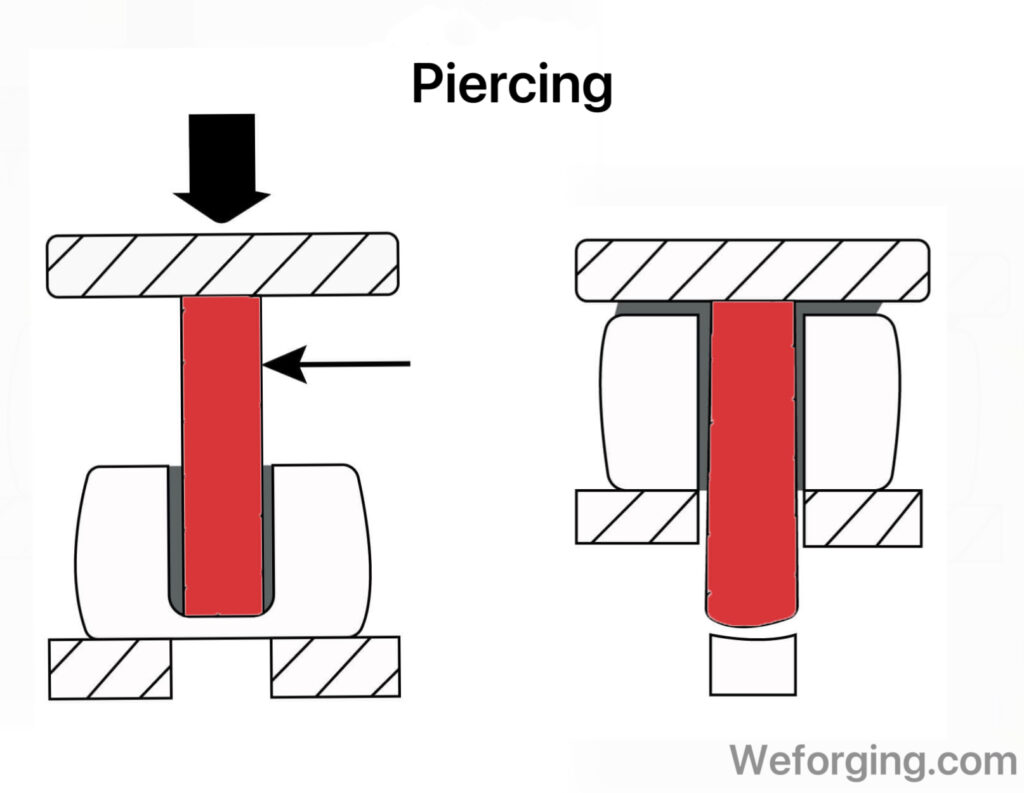

4. Punching (Piercing)

After pre-forming, the heated billet is carefully opened at the center using a hydraulic or mechanical press, forming a smooth, ring-shaped blank. This opening defines the initial inner diameter and allows easy mandrel placement for the next rolling stage. Precise punching supports even metal flow, excellent concentricity, and refined grain structure during ring expansion—providing strength, precision, and stability throughout the forging process.

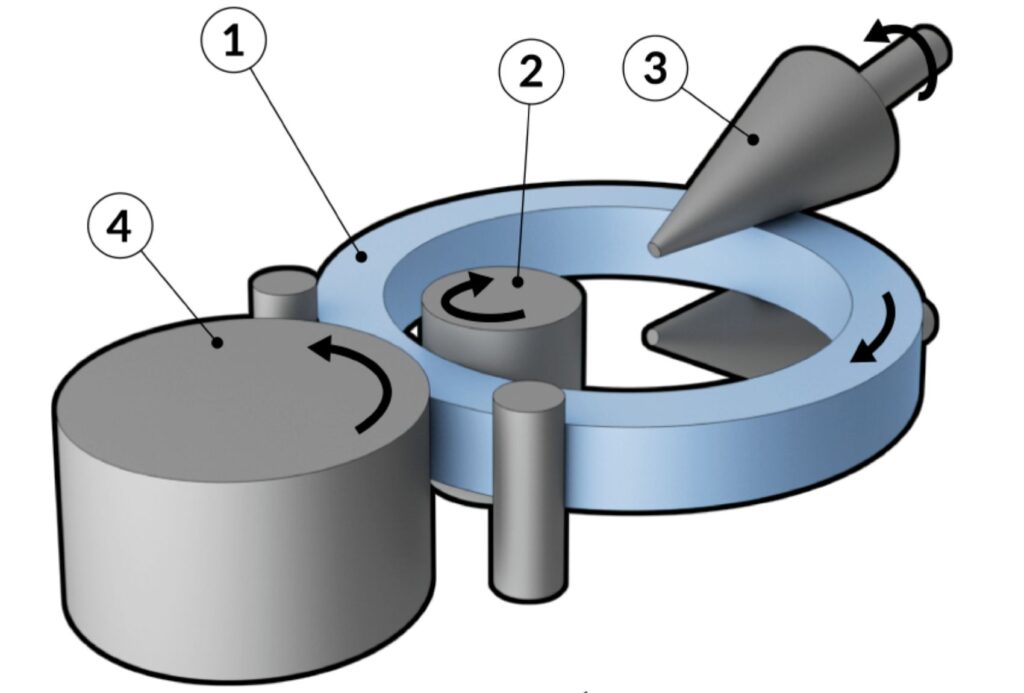

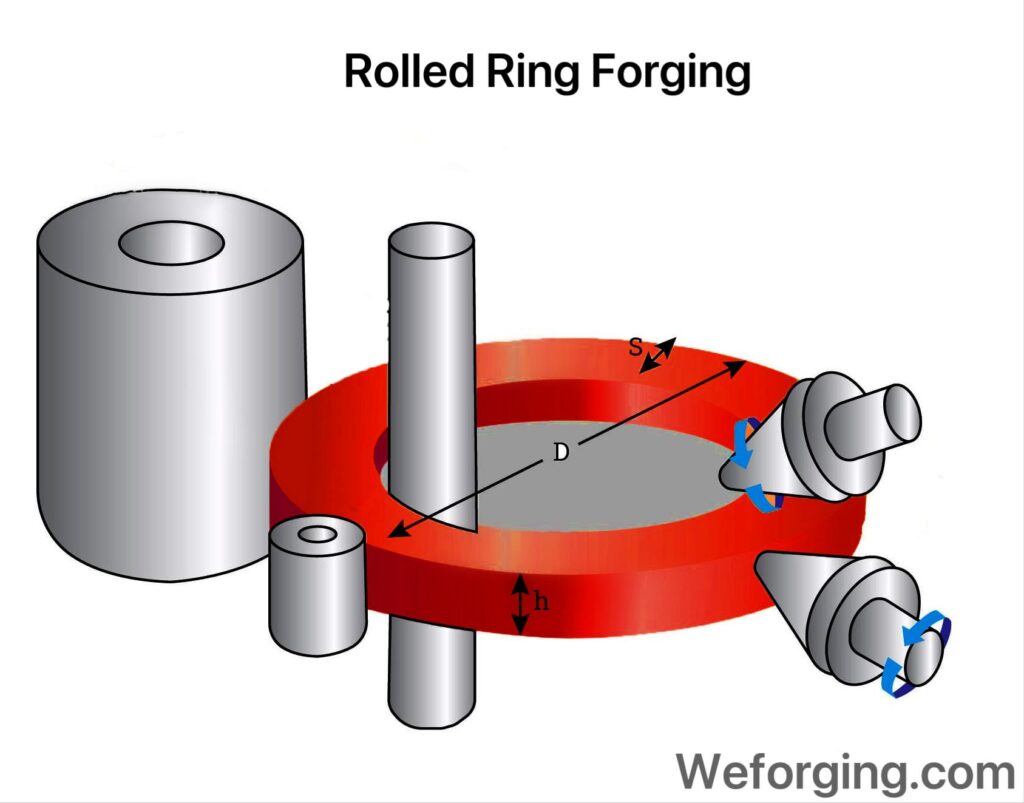

5. Ring Rolling (Ring Mill Forging)

The donut-shaped blank is placed onto a ring rolling mill, where it is rotated and gently shaped under controlled radial and axial pressure. This process expands both the inner and outer diameters to the desired dimensions with excellent precision. Ring rolling offers exceptional efficiency, maximizing material utilization and enhancing production consistency across every forged ring.

Throughout the process, our CNC machining technology ensures precision dimensions and tight tolerances, enabling us to deliver high-quality custom forging solutions.

Benefits of Rolled Ring Forging

Rolled ring forging offers both performance and production benefits. First, controlled grain flow enhances fatigue strength and impact resistance. Next, near-net shaping improves material use and reduces machining time. Additionally, each forged ring maintains concentricity and dimensional accuracy under extreme conditions. Moreover, the process supports carbon, alloy, and stainless steels, ensuring flexibility for different industries. Every ring is traceable, inspected, and tested to ensure consistent strength, density, and reliability.

Applications of Rolled Ring Forgings

Forged steel rings are used in many industrial systems requiring strength and reliability:

Wind Power:

Used in main bearing rings, yaw drives, and tower flanges for stability.Energy & Oil:

Applied in turbine casings, pressure vessels, and couplings for strength.Aerospace:

Used for jet engine rings and turbine housings requiring precision and heat resistance.Automotive:

Found in gear rings, wheel hubs, and transmission parts ensuring performance.Heavy Machinery:

Used in crane bearings, slewing rings, and drive shafts for durability.Mining Equipment:

Applied in crusher gears, drill joints, and conveyor shafts for reliability.

These rolled ring forgings ensure minimal distortion, improved fatigue resistance, and long service life across harsh operating environments.

Why Choose Weforging Manufacturing?

As a trusted custom forging manufacturer, Weforging provides complete rolled ring forging solutions—from billet cutting and forming to CNC machining, heat treatment, and final inspection.

🔩 Our Core Capabilities Include:

Custom forged rings produced from carbon steel, alloy steel, stainless steel, and other premium materials.

In-house CNC machining for tight tolerances and precise surface finishes.

Expertise in gear rings, flanges, and slewing bearings for critical applications.

Advanced heat treatment to improve strength, hardness, and long-term performance.

Full material traceability and quality assurance throughout every production stage.

By partnering with Weforging, you gain shorter lead times, optimized cost efficiency, and professional engineering support. Whether for a single custom ring or high-volume production, we deliver reliable forged components designed for your exact requirements.

Conclusion

Weforging specializes in rolled ring forging and forged steel rings, utilizing a fully integrated process that includes forging, CNC machining, heat treatment, and testing.Our advanced facilities, ISO 9001:2015 certified quality system, and experienced engineering team ensure the production of high-strength, precision-engineered components for global OEM and MRO clients.

Looking for a trusted ring forging manufacturer?

📩 Click the inquiry button below to upload your drawings or request a quotation.

Our engineering team will provide technical guidance and custom solutions tailored to your project.