Different Types of Nuts and Bolts

Understanding the main types of nuts and bolts is essential for choosing reliable industrial fasteners. These components are widely used in heavy machinery, wind turbines, construction equipment, and automotive systems. Selecting the right fastener type—such as hex bolts, lock nuts, or heavy-duty structural bolts—helps ensure strength, torque stability, and long service life. This guide provides a clear overview of the most common nuts and bolts, their applications, and how engineers and OEM buyers can select the best fasteners for demanding industrial environments.

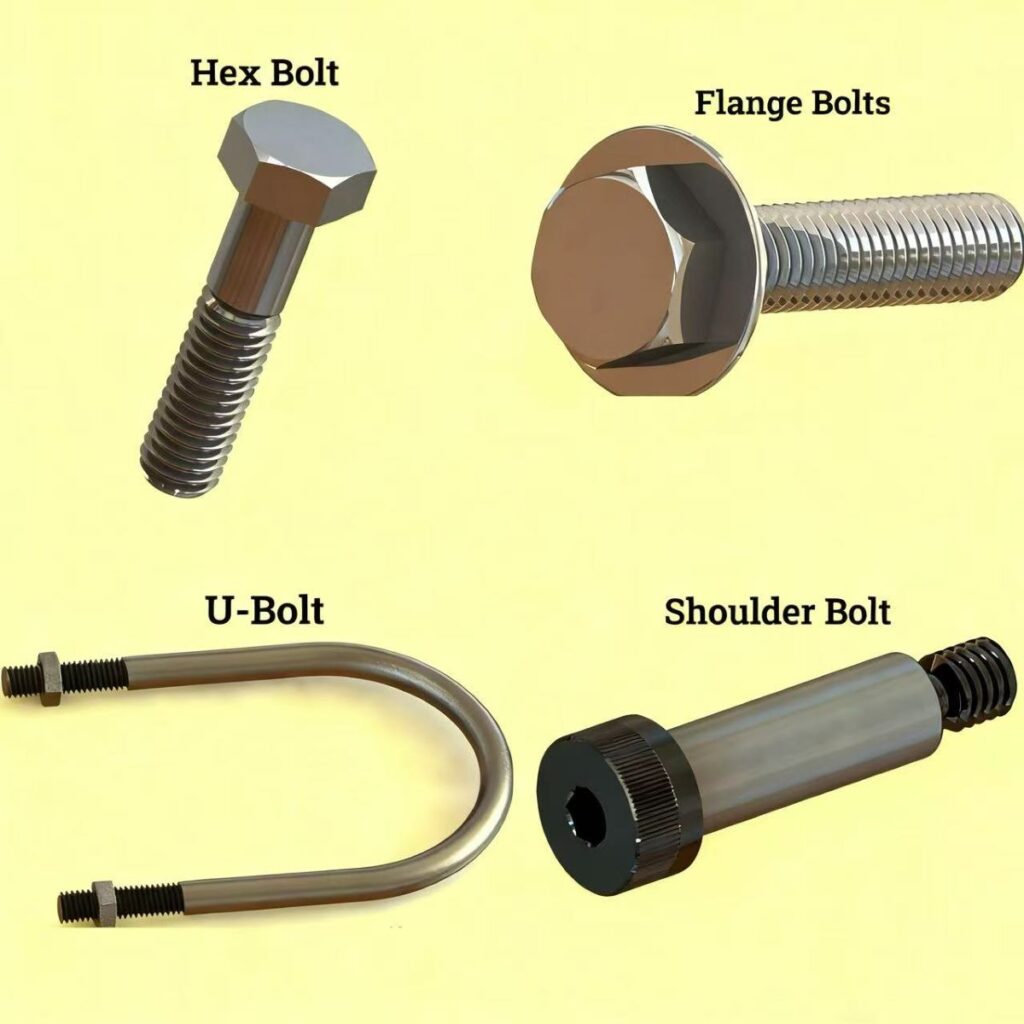

Bolts — Structure and Common Uses

Bolts are designed to create strong, stable connections under tension and shear. Their geometry, head shape, and strength grade determine performance under both static and dynamic loads. The most common bolt types include:

- Hex bolts– Used in structural assemblies and equipment frames

- Flange bolts– Provide a wider bearing surface for better load distribution

- U-bolts – Ideal for round components, pipes, and suspension systems

- Shoulder bolts– Used in machinery where precise alignment or sliding motion is required

These bolts are widely applied in construction machinery, wind-power systems, heavy-duty vehicles, gearboxes, and industrial frames. Proper bolt selection is essential for ensuring system stability and preventing fatigue failures.

Nuts — Materials and Major Categories

Industrial nuts come in various structural designs to meet different assembly requirements, locking performance, and installation methods. The most common nut types include:

- Hexagonal nuts – The standard fastening option for machinery, structures, and general industrial assemblies

- Castle nuts – Used with cotter pins to provide secure locking in dynamic or rotating systems

- Dome (cap) nuts – Protect exposed threads and offer enhanced safety and corrosion resistance

- Wing nuts– Designed for quick manual tightening without tools

- Nylon insert self-locking nuts – Prevent loosening under vibration using a built-in nylon ring

- T-nuts – Provide strong threaded connections in sheet metal, wood structures, and embedded mounting points

Engineers choose standard nuts or custom-forged CNC-machined nuts based on load, vibration, and installation needs.

Lock Nuts — Structure and Anti-Loosening Function

Lock nuts are designed for environments where vibration or torque reversal can loosen standard nuts. The most common lock-nut types include:

- Metal lock nuts – Use thread deformation or added friction

- Nylon insert lock nuts – Feature a nylon ring that increases friction and prevents loosening

- Prevailing-torque lock nuts – Use mechanical interference to maintain clamping force

Industries such as construction machinery, wind turbines, heavy transport, and mining equipment rely heavily on lock nuts due to their strong resistance to vibration and dynamic loading.

Lug Nuts — Automotive and Heavy-Equipment Applications

Lug nuts secure wheels on vehicles, trucks, and heavy machinery. The main types include:

- Conical seat lug nuts – Most common for commercial vehicles

- Ball seat lug nuts – Often used by European automotive manufacturers

- Flat seat lug nuts – Used in specialized wheel systems

These nuts must withstand lateral loads, rotational torque, and dynamic weight shifts. They are typically made from high-strength alloy steel and protected with coatings such as zinc plating, phosphating, or chrome finishing to resist corrosion and fatigue.

Industrial Bolts and Nuts for Heavy-Duty Applications

Industrial systems such as wind-power towers, excavators, cranes, hydraulic presses, and drilling equipment rely on high-strength fasteners designed for extreme load conditions. Examples include:

- Structural bolts for wind-turbine tower flanges

- Large-diameter nuts for excavators, cranes, and mining machinery

- Precision fasteners for gearboxes, sprockets, and transmission shafts

These fasteners must remain strong under high pressure, cyclic stress, temperature changes, and long operating cycles. Strength grades such as 8.8, 10.9, and 12.9 are widely used in demanding environments.

A well-known example is the Hong Kong–Zhuhai–Macao Bridge, where large-diameter forged nuts and high-strength bolts were installed in critical joints exposed to marine corrosion, wind loads, and long-term fatigue. This illustrates the essential role of reliable industrial fasteners in major infrastructure projects.

How to Choose the Right Fastener

Selecting the correct nuts and bolts is essential for safety and long-term reliability. Engineers should evaluate:

- Mechanical load and torque requirements – Consider tension, shear, and fatigue.

- Strength grade – Choose 8.8, 10.9, or 12.9 based on tensile strength needs.

- Material and corrosion protection – Options include zinc plating, hot-dip galvanizing, black oxide, and Dacromet.

- Forged vs. Machined fasteners – Forged fasteners provide superior grain flow and fatigue strength for structural loads.

Why OEMs Choose Weforging for Industrial Fasteners

Weforging offers an integrated manufacturing system that includes:

- Closed-die forging / hot forging / ring rolling for structural strength

- CNC machining for precise tolerance control

- Heat treatment for improved hardness and wear resistance

- Full inspection (CMM, UT, MPI, hardness, tensile, metallurgical tests)

We provide stable batch production, strict dimensional control, and reliable delivery for European and North American OEMs.

Conclusion

Nuts and bolts are essential components in mechanical and industrial systems. Understanding the main types of nuts and bolts—including lock nuts, lug nuts, structural bolts, and heavy-duty fasteners—helps engineers and buyers select solutions that improve safety, durability, and long-term performance.

Weforging supplies custom-forged and CNC-machined fasteners, including structural bolts, special-geometry nuts, high-strength fasteners, and OEM-specific designs. For custom industrial fasteners, drawings, or project support, you are welcome to contact us for technical assistance and quotations.

F.A.Q.

Forged bolts are ideal for applications requiring high strength, impact resistance, and superior fatigue performance—such as wind turbines, construction machinery, and heavy equipment. Machined bolts are suitable for complex geometries, small batches, or parts requiring high dimensional precision. For dynamic loads, vibration, or high torque conditions, forged bolts typically provide better long-term reliability.

These grades indicate tensile and yield strength levels. Higher numbers mean higher load capacity and better fatigue resistance. Grades 10.9 and 12.9 are commonly used in wind-tower flanges, lifting machinery, and mining equipment, where components must withstand high stress, cyclic loads, and harsh operating conditions.

Weforging can produce a wide range of custom forged and CNC-machined fasteners, including:

• Large-diameter structural bolts and nuts

• Forged flange bolts, shoulder bolts, and T-nuts

• Special-geometry nuts (castle nuts, cap nuts, wing nuts, etc.)

• High-strength alloy-steel fasteners (Grades 8.8 / 10.9 / 12.9)

• Bolts with holes, slots, internal hex, or weight-reduced hollow designs

These products are widely used in heavy machinery, wind-power systems, automotive components, and transmission assemblies.