What Is Upset Forging?

Upset forging, also known as heading or upsetting, is a precision metal-forming process used to enlarge the cross-sectional area of a heated billet by compressing it along its axis. This method refines the grain structure, increases strength, and improves dimensional uniformity. Unlike open die forging or closed die forging, upsetting in forging focuses on controlled deformation within short sections of a workpiece, making it ideal for producing shafts, bolts, flanges, and couplings that require enhanced toughness and axial strength. The upset forging process plays a vital role in industries such as automotive, energy, and heavy machinery, where structural reliability and consistent quality are essential.

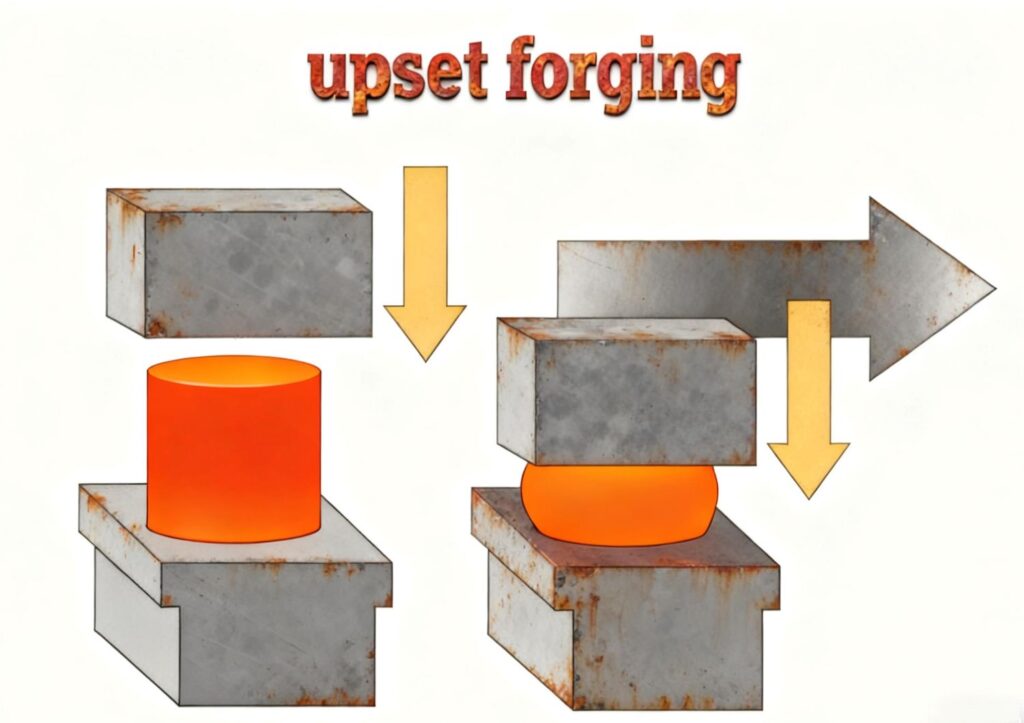

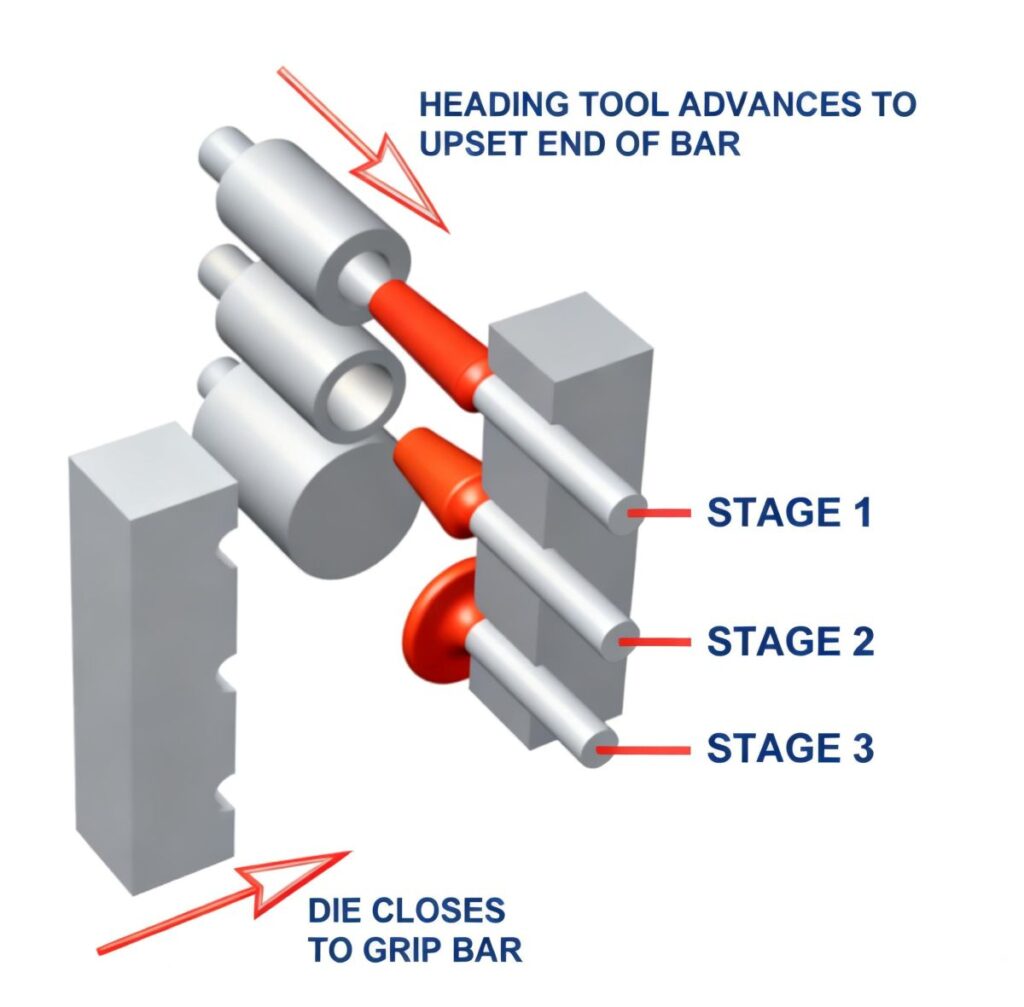

Upset Forging Process

The upset forging process starts by heating alloy or carbon steel billets to 1,050°C–1,250°C under controlled conditions. Once the billet reaches forging temperature, it is clamped in precision dies and axially compressed using hydraulic or mechanical presses. This controlled pressure causes the metal to flow outward, refining the grain structure and increasing density. Meanwhile, temperature and pressure are continuously monitored to ensure uniform deformation and material integrity. After forging, heat treatments such as normalizing, quenching, and tempering further enhance strength and toughness. Finally, CNC machining ensures dimensional accuracy, smooth surfaces, and precise geometry. This combination of steps makes upset forging ideal for producing flanges, bolts, and drive shafts with excellent consistency and performance.

Advantages of Upset Forging

Upset forging provides major advantages in manufacturing high-strength and precision-engineered components. By aligning the grain flow with the stress direction, it enhances tensile strength, fatigue resistance, and impact toughness. These properties are essential for components exposed to dynamic or cyclic loads. The controlled deformation refines the metal’s microstructure and improves internal integrity. This process ensures dimensional stability and extends service life. As a result, upset forging delivers consistent performance for critical industrial applications.

Beyond mechanical strength, it offers excellent efficiency in production. It forms near-net-shape parts with minimal material waste, reducing machining time and energy use. The process supports a wide range of materials, including alloy, carbon, and stainless steels. Additionally, it is suitable for both large-scale and custom production. When combined with precision heat treatment and CNC finishing, upset-forged parts achieve exceptional reliability and uniform quality in demanding environments.

Suitable Materials for This Forming Process

Upset forging is suitable for steels that show stable behavior during axial deformation and maintain strong forging grain flow in hot upset forging environments. Common material choices include:

• 1045 (C45 Medium Carbon Steel)

Reliable workability and balanced mechanical properties; often used for flanges, bar-end forming, and general machinery parts.

• 4140 / 42CrMo (Chromium-Molybdenum Steel)

High strength and consistent performance, making it ideal for shafts, couplings, and power-transmission components.

• Alloy Steels (e.g., 40Cr, 35CrMo)

Good hardenability and mechanical stability, suitable for parts requiring precise upset shapes.

• Stainless Steels (304, 316, 410)

Provide excellent surface quality and corrosion resistance for valves, flanges, and marine applications.

• Warm-Forging Grades

Designed for forming at 650–850°C, offering smooth deformation and improved dimensional control.

These materials support stable forming behavior and strong mechanical performance after forging and heat treatment, making them well-suited for automotive, energy, mining, and industrial machinery applications.

Applications of Upset Forging

Upset forging serves as a critical manufacturing process across multiple industrial sectors that demand high mechanical strength, reliability, and dimensional precision. Each industry applies the process differently to meet its unique engineering and performance standards.

- Automotive Industry:

Used to produce drive shafts, bolts, connecting rods, and steering components that endure torsional and vibrational stress.

The controlled grain flow achieved through upsetting enhances fatigue resistance and ensures consistent performance in high-volume production. - Agricultural Machinery:

Used for gear hubs, transmission shafts, and connecting joints that must resist vibration, shock, and heavy loading.The process enhances the durability and stability of tractors, harvesters, and soil-working equipment. - Aerospace and Heavy Machinery:

Aerospace systems and industrial machines rely on upset-forged rings, shafts, and load-bearing connectors that demand flawless internal structure and tight dimensional tolerance. The combination of forging, heat treatment, and CNC machining guarantees superior mechanical stability and alignment under extreme loads, ensuring performance reliability in engines, turbines, and transmission assemblies.

Through these diverse applications, upset forging supports critical industries by delivering components that combine strength, precision, and operational longevity, helping OEM manufacturers maintain high safety and performance standards.

Upset Forging vs Other Forging Methods

Forging Method | Key Characteristics | Advantages | Limitations |

Metal deforms freely under repeated hammering; suitable for large custom parts. | Flexible shaping, good for oversized or unique geometries. | Lower precision, inconsistent dimensions, more post-machining needed. | |

Metal fills enclosed dies to form complex shapes with high detail. | Excellent repeatability, ideal for intricate parts and mass production. | Higher tooling costs, limited size range, slower setup. | |

Upset Forging | Metal compressed axially to expand diameter; deformation confined locally. | Superior control, uniform grain flow, reduced waste, high material utilization, best for shafts, flanges, bolts. | Less suitable for complex shapes compared to closed die forging. |

The Role of Upset Forging in Cold Forging and Extrusion

In both cold forging and cold extrusion, the upset forging step plays a crucial role in shaping the metal blank before final forming. By increasing the cross-sectional area or forming the head of a component, this stage ensures proper material flow and optimal geometry for subsequent extrusion or forming operations. Controlled deformation at room temperature enhances precision, improves surface finish, and reduces machining needs. This makes cold upset forging an essential technique in the production of fasteners, shafts, and precision mechanical components used across automotive and industrial applications.

Conclusion

Upset forging remains a key process in the production of high-strength, precision components. Its ability to refine grain structure, improve density, and maintain dimensional accuracy makes it vital for modern engineering. Whether for automotive, energy, or heavy equipment applications, the upset forging process ensures reliable performance and long service life.

If you’re seeking a trusted forging partner for your next project, Weforging provides full-process solutions—from forging and CNC machining to heat treatment and testing—all under one quality management system.

Click the inquiry button below to request a real-time quote or upload your technical drawings.Our engineering team will review your specifications and provide a professional quotation tailored to your requirements.