What Does Forged Mean?

The term forged is widely used in manufacturing, engineering, and product descriptions. In practice, forged means metal shaped under compressive force rather than casting. This process improves grain structure and creates stronger, more reliable components. Understanding what does forged mean is essential for buyers and engineers because forged metal offers higher durability, tighter tolerances, and cost efficiency. Unlike cast or welded parts, forged products deliver superior performance in industries such as automotive, aerospace, and construction. By exploring the true forged meaning, procurement teams can make informed decisions and choose components that meet strict quality and safety standards.

Definition of Forged in Manufacturing

In manufacturing, forged describes components created by deforming metal under pressure, usually using hammers, presses, or dies. Unlike casting, where molten metal is poured into a mold, forging reshapes solid material to achieve desired geometry. The main difference between forged and cast parts lies in mechanical properties. Forged metal typically has higher strength, uniform grain structure, and better fatigue resistance, making it suitable for critical applications. In contrast, cast parts may contain internal voids or porosity that weaken performance.

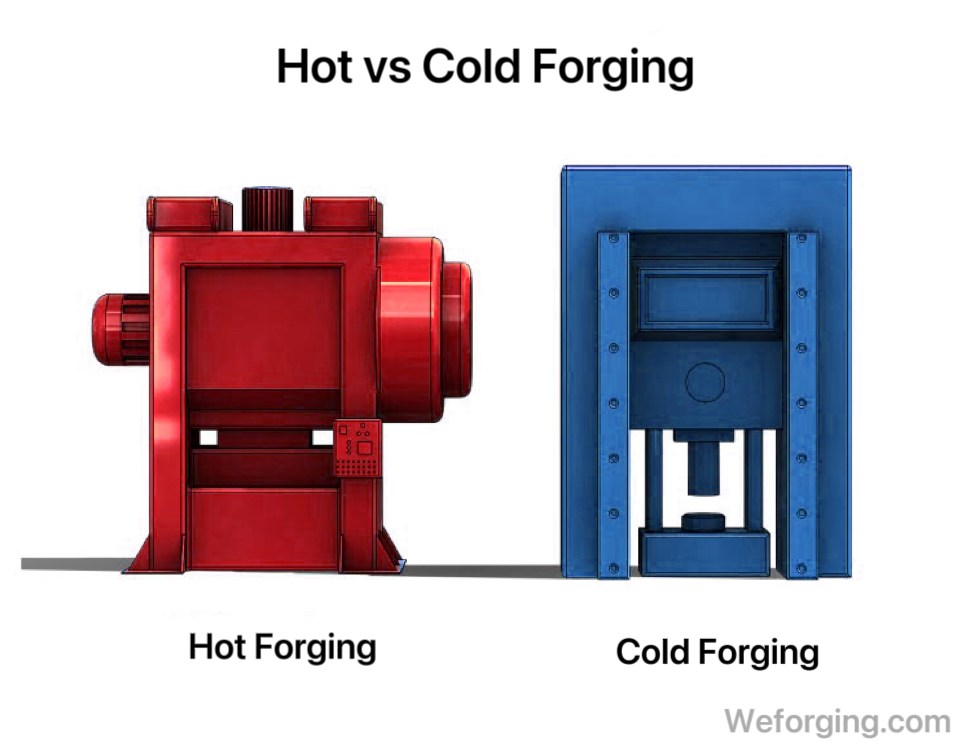

How Forging Works

Forging processes can be divided into several categories, including hot forging, cold forging, and closed-die forging. Hot forging involves heating the metal to improve plasticity, while cold forging uses immense pressure at room temperature to achieve tighter tolerances. In closed-die forging, dies shape the billet precisely into complex forms. Regardless of the method, forging improves grain alignment, resulting in parts with enhanced toughness and dimensional stability.

Advantages of Forged Metal

– Strength and Reliability – Forging refines the internal grain structure, resulting in parts with superior performance.

– Consistency – Forged metal shows uniform density, reducing risks of cracks and defects.

– Precision – Forged parts allow tighter tolerances, especially with CNC finishing.

– Cost Efficiency – Less material waste compared to machining.

– Durability – Fatigue resistance ensures longer service life.

Applications of Forged Components

Precision-formed parts are used across many industries:

Automotive: crankshafts, gear shafts, and suspension components.

Aerospace: landing gear, turbine discs, and structural fittings.

Construction and Energy: flanges, couplings, and wind turbine hubs.

Industrial Machinery: gears, bearings, and hydraulic parts.

These applications highlight why forging is a preferred choice for OEMs seeking reliability in critical systems.

Forged Products We Supply

At Weforging, our product portfolio covers a wide range of forged components designed for critical industries.

We specialize in:

- Forged shafts – For automotive, mining, and heavy machinery.

- Gear blanks and ring gears – Applied in transmissions, wind turbines, and industrial drives.

- Flanges – Used in pipelines, construction, and infrastructure projects.

- Sun gears and planetary gears – For compact and efficient power transmission.

- Fasteners – Including hex nuts, flange nuts, and anti-loosening systems.

By integrating forging, CNC machining, and heat treatment, we ensure high dimensional accuracy and durability.

Advanced inspections such as CMM measurement, ultrasonic testing, and metallography guarantee quality for global buyers.

Why Weforging Is a Reliable Forging Partner

At Weforging, we provide an integrated process that covers forging, machining, and testing. Every batch undergoes hardness verification, metallography, ultrasonic testing, and CMM inspection to ensure compliance with ISO and AGMA standards. We support customers across automotive, aerospace, wind power, and construction with customized designs and flexible production.

-1024x634.png)

Conclusion

For engineers and procurement specialists, understanding the meaning of forged goes beyond terminology. It ensures recognition of components that combine advanced forming methods, CNC machining, and strict testing.

At Weforging, we provide custom forged parts with complete traceability, certified to ISO and PPAP standards. Our process integrates forging, machining, and inspection to deliver precision, reliability, and shorter lead times for global buyers.

F.A.Q.

Forged parts are widely used in automotive, aerospace, wind power, heavy machinery, and infrastructure projects. At Weforging, we supply components such as shafts, gears, flanges, and fasteners to global OEMs and large-scale engineering projects.

Yes. We specialize in custom forged parts, covering weight ranges from 0.05 kg to 150 kg. With integrated forging, CNC machining, and heat treatment, we tailor products to meet specific material, size, and performance requirements.

Every batch undergoes strict inspections, including CMM measurement, ultrasonic testing, magnetic particle testing, metallography, and hardness checks. All products comply with ISO and AGMA standards, ensuring international buyers receive consistent and reliable quality.