What Is Metal Forging?

Metal forging is one of the oldest and most reliable manufacturing methods. For centuries, it has created durable, high-performance components. Unlike casting or welding, forging reshapes solid metal with compressive force. This process refines the grain structure and boosts strength.

To understand forging, we must look at the forging metal definition, the role of temperature of forging steel, and the function of modern forging equipment. Together with advanced forging methods, these factors shape the quality of forged parts. Today, the broad applications of metal forging include automotive, marine, mining, and heavy machinery. Forging remains essential for industries that demand reliability and efficiency.

Forging Metal Definition – The Basics

The forging metal definition is shaping metal with compressive forces from hammers, presses, or rollers. This process refines internal grain structure, increases toughness, and boosts fatigue resistance.

Forged parts combine strength with dimensional stability. Unlike subtractive machining, forging improves the metal’s natural properties. This makes metal forging ideal for gears, shafts, flanges, and fasteners.

Industries often choose custom forging for unique designs or special alloys. Today, forging integrates with CNC machining and inspection. Each part meets strict global standards.

Common Materials Used in Forging

Forging materials vary depending on the part’s application and required strength. The most common are steel, aluminum, copper, and titanium.

Material | Properties | Applications |

Carbon Steel | Toughness, fatigue resistance, cost-efficient | Automotive and heavy equipment |

Stainless Steel | Corrosion resistance, high pressure strength | Marine, chemical, food processing |

Aluminum | Lightweight, strong, machinable | Aerospace, transportation |

Copper/Brass | Conductivity, durability | Electrical, plumbing, fittings |

Titanium | Strength-to-weight, corrosion resistant | Aerospace, defense, medical devices |

Temperature of Forging Steel – Why Heat Matters

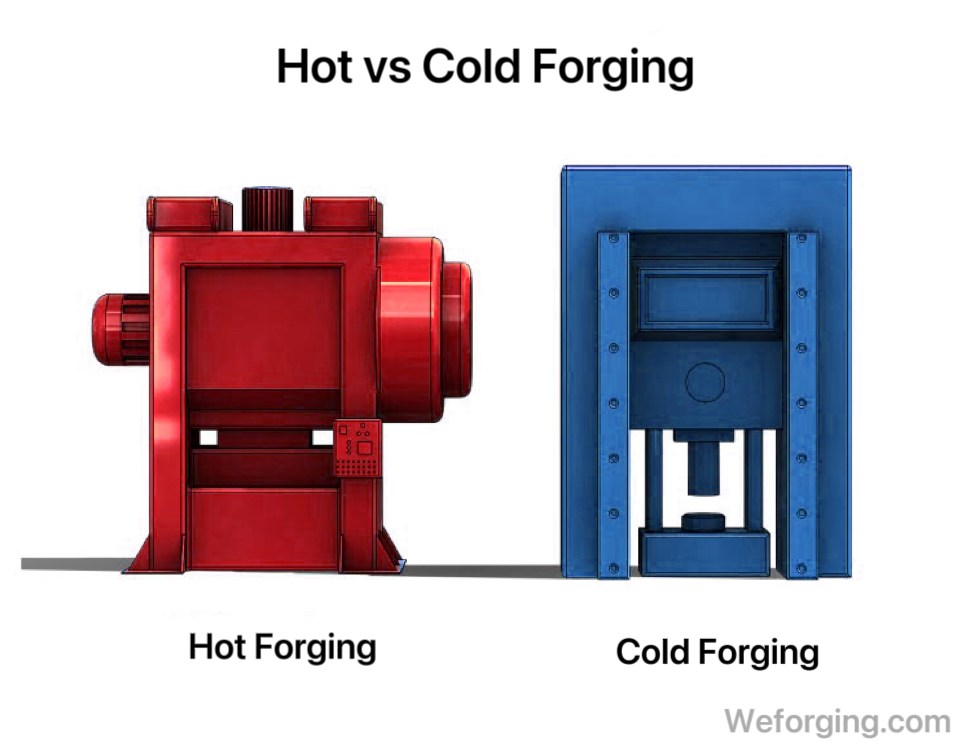

The temperature of forging steel plays a decisive role in shaping and performance. When hot forging, the metal is heated above its recrystallization point. At this stage, steel becomes more ductile, which allows deformation with minimal resistance and ensures even grain flow. This method is commonly used for producing large components such as flanges, shafts, and heavy-duty fasteners where toughness and strength are critical.

By contrast, cold forging occurs at or near room temperature. It requires greater force because the steel is less ductile, but the process provides excellent surface finishes, tighter tolerances, and improved dimensional accuracy. Cold forging is often chosen for small precision components like nuts, bolts, and bushings.

Both methods have unique advantages, and modern manufacturers often combine hot and cold forging with CNC machining to achieve optimal balance between strength, precision, and efficiency.

Forging Equipment – Tools and Technology

At Weforging, we combine traditional forging techniques with advanced digital tools. While drop hammers and mechanical presses were once the backbone of production, our workshops now operate with hydraulic presses capable of shaping heavy-duty parts for mining and construction. These presses provide stable pressure and ensure the durability required for demanding industries.

In addition, we integrate Mazak CNC machining centers and CMM inspection systems directly into our forging process. This allows us to deliver forged components with tight tolerances, smoother finishes, and consistent quality. For clients in automotive, marine, and heavy equipment, this means shorter lead times and higher reliability.

By aligning forging equipment with precision machining and strict testing, Weforging offers more than just standard solutions. We provide customized forging services that meet international standards and adapt to the unique needs of every customer.

Forging Methods and Applications

Different forging methods serve different needs. Open-die forging works for large flexible shapes. Closed-die forging creates accurate smaller parts in high volume. Upset forging makes bolts, fasteners, and shafts stronger.

Applications of metal forging cover many industries. Automotive uses crankshafts, connecting rods, and gears for durability. Energy and heavy equipment require forged flanges and pressure parts to ensure safety. Marine sectors use forged shafts and couplings for reliability under stress.

Conclusion

Metal forging remains one of the most reliable processes for producing high-performance parts. From temperature control to advanced equipment and forging methods, it ensures strength, durability, and efficiency that casting or welding cannot match.

At Weforging, we combine traditional forging expertise with modern tools such as Mazak CNC machining centers and CMM inspection systems. This integration allows us to deliver forged components with tighter tolerances and consistent quality for industries like automotive, mining, marine, and heavy machinery. By offering custom forging solutions, we meet international standards while adapting to each client’s unique requirements, making us a trusted partner worldwide.

Contact

Submit Your Requirements:

- Upload 2D/3D Drawings(PDF, DWG, DXF, STEP, IGES).

- Specify Material & Quantity & Technical Requirements

- Receive free DFM feedback within 24h.