Open Die Forging vs Closed Die Forging

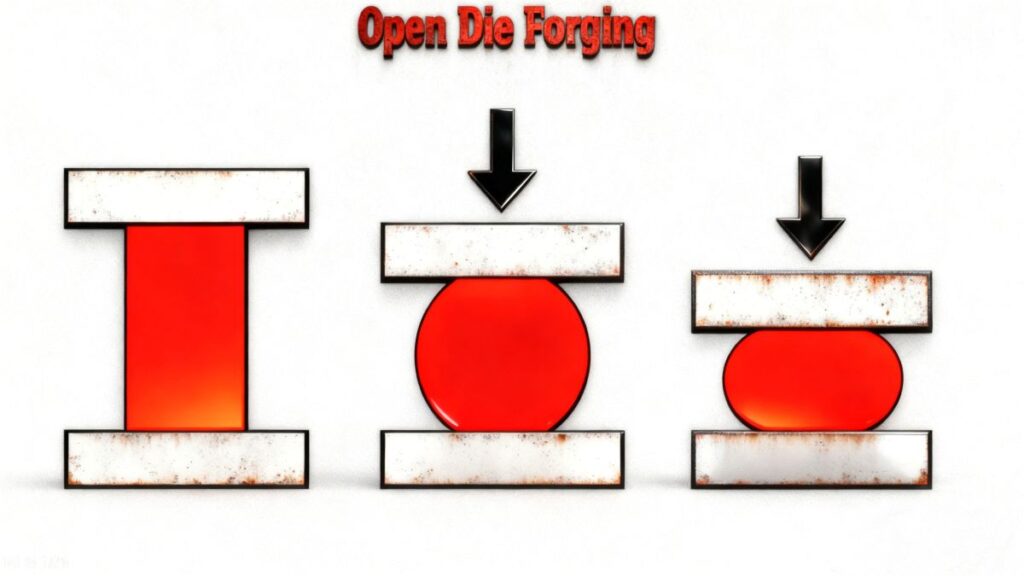

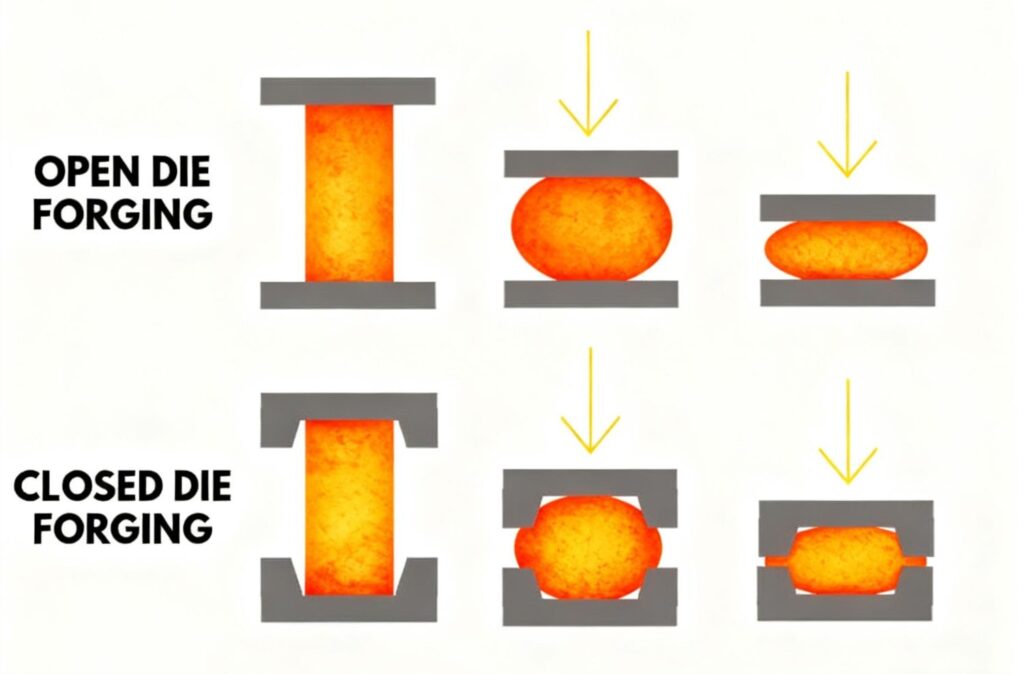

When it comes to shaping and strengthening metal, forging is one of the most established manufacturing processes. Within this field, two widely used methods—open die forging and closed die forging—are based on similar heating and deformation principles but differ in how the dies interact with the metal.Open die forging allows the metal to flow freely between flat or simple dies, while closed die forging confines the metal within a cavity to achieve an exact shape and tolerance.

This article introduces the basic concepts of both metal forging methods, explains how each process works, compares their differences, and highlights where each is most effectively applied.

What Is Open Die Forging

Open die forging, also known as free forging, uses flat or simple dies that do not completely enclose the metal. The heated workpiece is shaped through repeated compressions, allowing excellent control of internal grain flow and structural integrity. This process is ideal for large and heavy components such as :

At Weforging, open die forgings range from 50 kg to 8 tons, made from alloy, carbon, and stainless steels. Each piece undergoes CNC machining, heat treatment, and ultrasonic or MPI testing to ensure dimensional precision and stable mechanical performance.

What Is Closed Die Forging

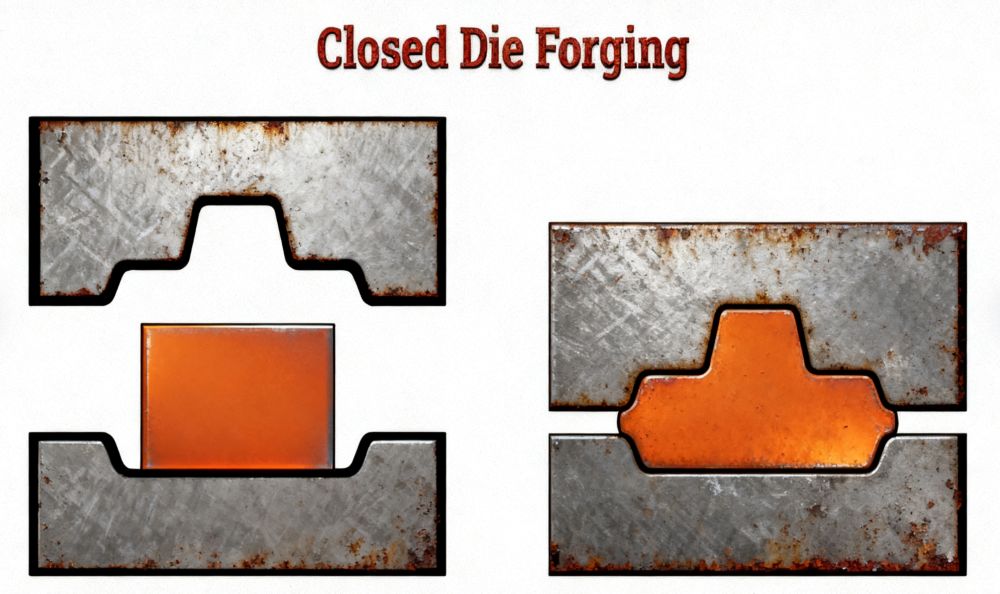

Closed die forging, also known as impression-die forging, forms heated metal inside precision-shaped dies that fully enclose the material. Under high pressure, the metal fills the cavity and takes the final shape of the part.

This process offers high dimensional accuracy, surface quality, and strength consistency, making it ideal for small to medium-sized precision components, such as:

- forged gears

- connecting rods

- valve bodies

At Weforging, each closed die forging is produced using automated lines and Mazak CNC centers, with full testing to ensure ISO 9001:2015 and AGMA compliance.

Key Differences Between Open and Closed Die Forging

Aspect | Open Die Forging | Closed Die Forging |

Die Structure | Uses flat or simple dies | Uses precision-designed enclosed dies |

Part Size | Large and heavy components | Small to medium-sized parts |

Dimensional Accuracy | Moderate precision | High precision and repeatability |

Tooling Cost | Lower tooling investment | Higher initial die cost but efficient per part |

Typical Products | Shafts, rings, flanges, discs | Gears, rods, valve bodies, flange nuts |

Production Volume | Ideal for low-to-medium quantities | Suitable for mass production |

Material Flow | Controlled by operator or automation | Confined within the die cavity |

Advantages of Open Die Forging and Closed Die Forging

Each forging method offers distinct benefits depending on the part size, complexity, and production volume.

- Open Die Forging Advantages:

This process provides excellent control of grain flow, resulting in superior strength, toughness, and fatigue resistance. It allows greater flexibility for producing large or custom-shaped components without expensive molds. Open die forging also enables easier material testing and structural refinement, making it ideal for heavy-duty shafts, flanges, and power-transmission parts. - Closed Die Forging Advantages:

Closed die forging ensures high dimensional accuracy and repeatability, making it perfect for high-volume or precision applications. The enclosed die cavity allows for complex geometries and tighter tolerances while minimizing post-machining. It also improves material utilization and surface finish, offering consistent quality for gears, connecting rods, and hydraulic components.

Together, these two processes allow manufacturers to balance cost, precision, and mechanical performance—covering a wide range of industrial requirements.

How to Choose Between Open and Closed Die Forging

Selecting the right forging method depends on part size, tolerances, geometry, material grade, and machining requirements. Below is a clear decision guide for engineers and procurement teams.

Key Decision Factors

1. Part Size & Weight

> 500 kg → Open Die Forging

< 200 kg → Closed Die Forging

2. Complexity of Geometry

Simple or straight shapes → Open die

Ribbed, contoured, or intricate shapes → Closed die

3. Dimensional Tolerance Requirements

Moderate tolerances → Open die

Tight assembly tolerances → Closed die

4. Batch Size

Prototypes / small batches → Open die

Medium to high-volume production → Closed die

5. Material Grade

Heat-resistant alloys often benefit from open-die deformation

(Better grain flow and structural refinement)

6. CNC Machining Requirements

Open die → More machining needed

Closed die → Reduced machining time & cost

Conclusion

Both open die and closed die forging play vital roles in modern manufacturing. Open die forging provides flexibility for large components, while closed die forging offers precision for complex parts. With complete forging + CNC + testing capabilities, Weforging delivers reliable, high-performance solutions tailored to every industry.

If you are looking for custom metal forging solutions or need technical support for your project, you are welcome to contact Weforging to discuss your drawings or request a quotation.

F.A.Q.

The choice depends on your part’s size, geometry, and required accuracy. Open die forging is ideal for large or custom components, while closed die forging is better for high-precision or high-volume production. Weforging’s engineering team can evaluate your drawings and recommend the most cost-effective process.

To prepare an accurate quotation, please provide material grade, rough dimensions, annual quantity, and any special heat treatment or machining requirements. 3D drawings or reference samples are also helpful for tooling design and process planning.

Every forging undergoes full process control—from billet heating and forming to CNC machining and inspection. Weforging applies ultrasonic, MPI, hardness, and dimensional tests to ensure each part meets international standards such as ISO and AGMA.